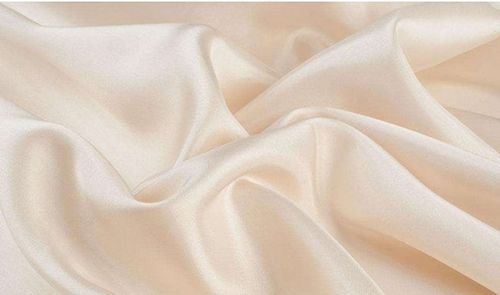

Light and thin fabrics are especially suitable for use in areas and climates with high temperatures. Common special light and thin fabrics include silk, chiffon, georgette, glass yarn, crepe, lace, etc.It is loved by people all over the world for its breathability and elegant feel, and accounts for a large proportion of my country's exports.

What problems are likely to occur in the production of light and thin fabrics, and how to deal with them? Let’s sort it out together.

Cause analysis: Seam wrinkling directly affects the quality of garments. The common causes are seam shrinkage caused by excessive seam tension, seam shrinkage caused by uneven fabric feeding, and seam shrinkage caused by uneven shrinkage of surface accessories. wrinkle.

Process solutions:

The suture tension is too tight:

① Try to loosen the tension between the sewing thread, the bottom line and the fabric, and the overlock thread as much as possible to avoid shrinkage and deformation of the fabric;

② Adjust the stitch density appropriately, and the stitch density is generally adjusted to 10-12 inches per inch. Needle.

③Choose sewing threads with similar fabric elasticity or smaller stretch rates, and try to use soft and thin threads, such as short fiber sewing threads or natural fiber sewing threads.

Uneven shrinkage of surface accessories:

① When selecting accessories, special attention should be paid to the fiber composition and shrinkage rate, which should be consistent with the characteristics of the fabric, and the difference in shrinkage rate should be controlled within 1%.

② Before putting into production, the fabric and accessories must be pre-shrunk to find out the shrinkage rate and observe the appearance after shrinkage.

2. Draw yarn

Reason analysis: Because the yarn of light and thin fabrics is thin and brittle, during the high-speed sewing process, the fibers are easily hooked out by blunt-damaged feed teeth, presser feet, machine needles, needle plate holes, etc., or due to rapid and frequent punctures by the machine needle. The movement pierces the yarn and tightens the surrounding yarn, commonly known as "drawing yarn". For example, when punching buttonholes with a blade on a door-cutting machine, fibers around the buttonholes are often pulled out by the blades. In severe cases, yarn detachment defects may occur.

Process solutions:

① In order to prevent the machine needle from damaging the fabric, a small needle should be used. At the same time, pay attention to choosing a needle with a round tip. The following are several needle models suitable for light and thin fabrics:

A Japanese needle: needle size 7~12, S or J-shaped needle tip (extra small round head needle or small round head needle);

B European needle: needle size 60~80, Spi tip (small round head needle);

C American needle: needle size 022~032, Ball Tip needle (small round head needle)

② The size of the needle plate hole must be changed in accordance with the model of the needle. Small-sized needles need to be replaced with needle plates with small holes to avoid problems such as stitch skipping or thread drawing during sewing.

③Replace with plastic presser feet and feed dogs covered with plastic molds. At the same time, pay attention to the use of dome-shaped feed dogs, and timely replacement of blunt-damaged feed parts, etc., which can ensure smooth conveyance of cut pieces and reduce yarn draw and Problems such as snagging and damage to the fabric occur.

④ Applying glue or adding adhesive lining to the seamed edge of the cut piece can reduce the difficulty of sewing and reduce the damage to the yarn caused by the sewing machine.

⑤Choose a button door machine with a straight blade and a knife rest pad. The blade movement mode uses downward punching instead of horizontal cutting to open the buttonhole, which can effectively prevent the occurrence of yarn drawing.

3. Sewing marks

Cause analysis: There are two common types of seam marks: "centipede marks" and "tooth marks." "centipede marks" are caused by the yarn on the fabric being squeezed after the stitches are sewn, causing the stitch surface to be uneven. Shadows are shown after light reflection; "teeth marks" are caused by the seam edges of the thin, soft and light fabrics being scratched or scratched by feeding machines such as feed dogs, presser feet, and needle plates. An obvious trace.

"Centipede pattern" process solution:

① Try to avoid making multiple rows of wrinkled styles on the fabric, reduce or use no lines to cut structural lines, consider using diagonal lines instead of straight and horizontal lines in parts that must be cut, and avoid cutting in the direction of straight grains with dense tissue. Cut the lines and sew the pieces.

② Reduce or increase the amount of space: use simple seam folding to process the raw edges and sew the fabric with a single line, without pressing or less pressing the decorative topstitch.

③Do not use the needle feed device to transport fabrics. Since double-needle machines are equipped with needle feed devices, you should avoid using double-needle machines to capture double rows of topstitching. If the style does have a design for capturing double-row topstitching, you can use a single-needle sewing machine to capture double threads separately.

④ Try to cut the pieces along the twill or straight diagonal direction to reduce the appearance of fabric ripples.

⑤Choose thin sewing thread with fewer knots and smoothness to reduce the space occupied by the sewing thread. Do not use a presser foot with obvious grooves. Choose a small round-mouth machine needle or a small-hole machine needle to reduce the damage of the machine needle to the fabric yarn.

⑥ Use the five-thread overlocking method or chain stitch instead of flat stitch to reduce yarn squeezing.

⑦Adjust the stitch density and loosen the thread tension to reduce the sewing thread hidden between the fabrics.

"Indentation" process solutions:

①Loosen the pressure of the presser foot, use diamond-shaped or domed fine feed teeth, or use a plastic presser foot and feed teeth with a rubber protective film to reduce damage to the fabric by the feeder.

② Adjust the feed dog and the presser foot vertically so that the forces of the feed dog and the presser foot are balanced and offset each other to prevent damage to the fabric.

③ Glue lining to the seam edges, or put paper on seams where marks are prone to appear, to reduce the appearance of marks.

4. Stitch swing

Cause analysis: Due to the loose cloth feeding parts of the sewing machine, the cloth feeding operation is unstable, and the pressure of the presser foot is too loose. The stitches on the surface of the fabric are prone to skew and wobble. If the sewing machine is removed and re-sewn, needle holes are easily left, resulting in a waste of raw materials. .

Process solutions:

①Choose a small needle and a needle plate with small holes.

② Check whether the screws of the feed dog are loose.

③Slightly tighten the stitch tension, adjust the density of the stitches, and increase the tension of the presser foot.

Reason analysis: When the sewing machine is stopped during sewing, the oil cannot return to the oil pan quickly and attaches to the needle bar to contaminate the cut pieces. Especially thin silk fabrics are more likely to absorb and seep from the machine tool and feed teeth when stitched with a high-speed sewing machine. Spilled engine oil.

Process solutions:

① Choose a sewing machine with an excellent oil transport system, or a specially designed sealed oil transport sewing machine. The needle bar of this sewing machine is made of alloy and is coated with a layer of chemical agent on the surface, which can resist friction and high temperature, and can effectively prevent oil spillage. . The oil delivery volume can be automatically adjusted in the machine tool, but the cost is high.

② Regularly check and clean the oil circuit. When oiling the sewing machine, only fill half a box of oil, and turn down the throttle of the oil pipe to reduce the amount of oil delivered. This is also an effective technique to prevent oil spillage.

③Slowing down the vehicle speed can reduce oil leakage.

④Switch to a micro-oil series sewing machine.

Post time: Feb-26-2024