Ukuphepha kwama-excavators ayimishini kuhlobene nezinyathelo zobuchwepheshe zokuqeda noma ukunciphisa izingozi ezibangelwa izingozi ezinkulu, izimo eziyingozi noma izehlakalo eziyingozi ekusetshenzisweni, ekusebenzeni nasekunakekeleni ukwakhiwa kwe-earthwork.Yimaphi amazinga okuhlola ama-excavators ngomshini?Ahlolwa kanjani ama-excavators ngomshini?

Mechanical Excavator

Ama-excavators emishini abhekisela kubavubukuli abanezakhiwo zabo eziphezulu ezisebenza ngezintambo zocingo.Ikakhulukazi basebenzisa amafosholo okuhudula, amafosholo angaphambili noma amabhakede okubamba ukuze kumbiwe;sebenzisa amapuleti e-tamping ukuze uthinte izinto;sebenzisa izingwegwe noma amabhola ekusebenzeni kokuchotshozwa;futhi usebenzise izinto zokusebenza ezikhethekile nezinanyathiselwa.Yenza ukuphatha impahla.

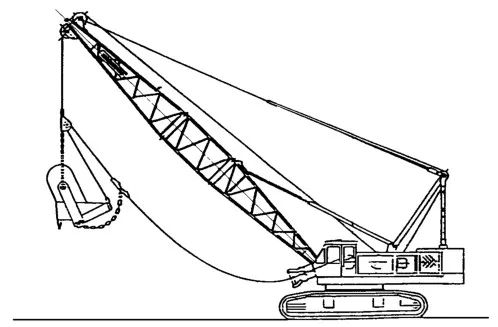

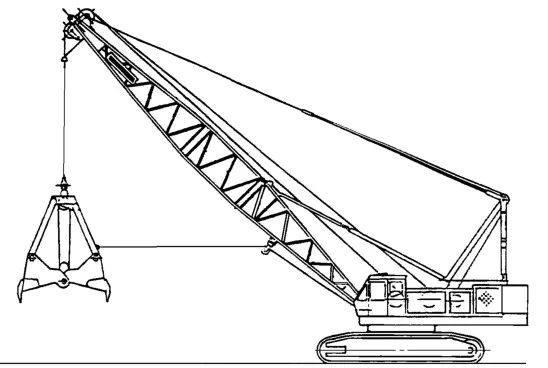

I-Crawler mechanical excavator enezinto zokubamba

Mechanical Excavatorizimfuneko ezijwayelekile zokuhlola

01Ukuhlolwa kwe-Mechanical Excavator-ukuhlolwa kwendawo yokusebenza komshayeli

-Izisetshenziswa

Ikhebhu yomshayeli kufanele ifakwe endaweni yomshayeli emshinini wokugibela.

Imishini enesisindo esingaphezu kuka-1,500 kg kanye nendawo yomshayeli kufanele ifakwe ikhebhu yokushayela.Imishini enesisindo esingaphansi noma esilingana no-1,500 kg ayidingeki ukuthi ifakwe ikhebhu yomshayeli.

Imishini enyakazayo kufanele yakhelwe ukuqinisekisa ukuthi izinsimbi zokuvikela ezanele ziyafakwa uma zisetshenziswa lapho kunobungozi bemfucumfucu endizayo (isb. ukusebenzisa ama-hydraulic).

-Indawo encane yokusebenza

Isikhala esincane sokunyakaza sabashayeli kufanele sihambisane ne-ISO 3411.

Isikhala esincane sendawo yomshayeli nendawo yezilawuli kufanele kuhambisane ne-ISO 6682

-Izingxenye ezihambayo

Izinhlinzeko kufanele zenziwe ukugwema ukuthintana ngengozi endaweni yomshayeli nezingxenye ezihambayo njengamasondo, amabhande noma izinto zokusebenza noma okunamathiselwe.

- Ukuphela kwenjini

I-exhaust gas evela enjinini kufanele igcinwe kude nomshayeli kanye ne-air inlet ye-cab

- Ukuthenga kanye nediphozi yelayisensi yokushayela

Kufanele kuhlinzekwe isikhala eduze nendawo yomshayeli ukuze kugcinwe ngokuphephile imanuwali yomshayeli noma ezinye iziqondiso zokusebenza.Uma indawo yomshayeli ingakwazi ukukhiywa noma lingekho ikhabhu yomshayeli, isikhala kufanele sikhiyeke.

-Iziphetho ezicijile

Akufanele kube khona imiphetho ecijile esobala noma amakhona endaweni yokusebenzela yomshayeli (njengosilingi, iphaneli yensimbi yangaphakathi kanye nephaseji eliya endaweni yomshayeli).

-Izimo zezulu endaweni yomshayeli

Ikhebhu yomshayeli kufanele ivikele umshayeli ezimweni zezulu ezibonakala zingesihle.Amalungiselelo ezinhlelo zokungenisa umoya, izinhlelo zokushisa eziguquguqukayo kanye nezinhlelo zokuqeda ingilazi kufanele zifakwe ngokuhambisana nemithethonqubo.

-Amapayipi aqinile namapayipi

Ikhebhu ifakwe umfutho we-liquid omkhulu kuno-5 MPa noma izinga lokushisa elingaphezu kuka-60 C kanye namapayipi.

-Basic yokungena nokuphuma

Ukuvulwa kokufinyelela okuyisisekelo kuzohlinzekwa, ubukhulu bayo obuzohambisana ne-ISO 2867.

- Enye indlela yokungena nokuphuma

Enye indlela yokungena/yokuphuma izohlinzekwa ngakolunye uhlangothi olusuka endaweni yokuqala yokungena/yokuphuma.Ubukhulu bayo buzohambisana ne-ISO 2867. Lokhu kungaba iwindi noma omunye umnyango ongavuleka noma uhanjiswe ngaphandle kokhiye noma amathuluzi.Uma umnyango ungavulwa ngaphakathi ngaphandle kokhiye noma amathuluzi, sebenzisa i-latch.Izicabha zengilazi eziphukayo namafasitela anosayizi ofanele angase abhekwe njengezinye izindlela zokuphuma ezifanele, inqobo nje uma isando sokuphunyuka esidingekayo sinikezwe kukhebhu futhi sibekwe endaweni lapho umshayeli angafinyelela khona.

-Isistimu yokungenisa umoya

Uhlelo lokungenisa umoya kufanele lukwazi ukunikeza umoya ohlanzekile ekhebhuni yomshayeli ngesilinganiso sokugeleza esingekho ngaphansi kwama-43 m/h.Izihlungi zizohlolwa ngokuhambisana ne-SO 10263-2.

-Isistimu ye-Defrost

Isistimu yokuqeda iqhwa kufanele ihlinzeke ngemishini yokuqeda isithwathwa yamafasitela angaphambili nangemuva, njengokusebenzisa isistimu yokushisisa noma idivayisi yokuqeda iqhwa.

-Isistimu yokushaja

Uma i-cab enohlelo lwe-pressurization inikezwa, uhlelo lwe-pressurization luzohlolwa ngokuhambisana nezinhlinzeko ze-SO 10263-3 futhi lunikeze ukucindezela kwangaphakathi okuhlobene okungengaphansi kwama-50 Pa.

-Iminyango namafasitela

Iminyango, amafasitela kanye nama-flap kufanele kuvinjelwe ngokuphephile ezindaweni ezihlosiwe zokusebenza.Iminyango kufanele ibanjwe endaweni yayo yokusebenza okuhloswe ngayo yizithiyo eziqinile eziklanyelwe ukugcina ukuvuleka okuphephile kwendawo yokungena nokuphuma endaweni okuhlosiwe yokusebenza, futhi imingcele kufanele ikhululwe kalula endaweni yomshayeli noma endaweni yokungena yomshayeli.

Amafasitela ezimoto kufanele afakwe ngokuphepha noma ezinye izinto ezinokusebenza okufanayo kokuphepha.

Amafasitela angaphambili kufanele afakwe amawipha kagesi namawasha.

I-tank yamanzi ye-washer yefasitela kufanele ifinyeleleke kalula.

-Ukukhanya kwangaphakathi

I-cab yomshayeli kufanele ifakwe umshini wokukhanyisa wangaphakathi ongaguquki, okufanele usasebenza ngemva kokucisha injini, ukuze indawo yomshayeli ikhanyise futhi ifunde incwadi yokushayela.

- Isivikelo somshayeli

Ama-excavators angama-mechanical kufanele akwazi ukufaka izakhiwo zokuvikela umshayeli (onogada abaphezulu nabaqaphi bangaphambili).Umkhiqizi kufanele ahlinzeke ngezakhiwo zokuzivikela (onogada abaphezulu nabaqaphi bangaphambili), okufanele bakhethwe umsebenzisi ngokusekelwe ezingozini ezikhona zohlelo lokusebenza.

-Isakhiwo sokuvikela sezinto eziwayo (FOPS)

Ngaphandle kwalokho okuhlukile okushiwo ku-ISO3449, ama-cranes ayisikwele okulindeleke ukuthi asetshenziswe ezindaweni ezinezingozi zezinto eziwayo kufanele adizayinelwe ukuthi akwazi ukufaka isakhiwo sokuvikela into ewayo (FOPS).

02Ukuhlola I-Mechanical Excavator -Izilawuli Zomshayeli Nezinkomba

-Qala futhi umise idivayisi

Imishini enyakazayo kufanele ifakwe izinto zokuqalisa nokumisa (ezifana nezikhiye), futhi isistimu yokuqala kufanele ifakwe izinto zokuzivikela ukuze kuvinjelwe ukusetshenziswa okungagunyaziwe.

Imishini enyakazisa umhlaba izoklanywa ngendlela yokuthi lapho injini iqalwa noma imiswa, akunakwenzeka ukuhambisa umshini, izinto zokusebenza nezinamathiselo ngaphandle kokuqalisa izilawuli.

-Ukusebenza okungalindelekile

Amadivayisi okulawula angabangela ingozi ngenxa yokusebenza kwengozi kufanele ahlelwe noma acishwe noma avikelwe ngokuvumelana nesimiso sokunciphisa ubungozi.Ikakhulukazi, lapho umshayeli engena futhi ephuma endaweni yomshayeli, idivayisi evimbela isilawuli kufanele izisebenze yona, noma Ivuselelwe ngenkani futhi yenziwe isebenze ngamadivaysi afanelekile.

-i-pedal pedal

Kufanele kube nosayizi ofanele, umumo kanye nesikhala esanele phakathi kwazo.Ukunyathela kufanele kube nendawo engasheleli futhi kube lula ukuyihlanza.Uma ama-pedals emishini ehambisa umhlaba kanye nama-pedals ezimoto anemisebenzi efanayo (i-clutch, i-braking ne-acceleration), ukuze ugweme ingozi ebangelwa ukuxuba, ama-pedals kufanele ahlelwe ngendlela efanayo.

- Ukufika okuphuthumayo kokunamathiselwe

Uma injini igxilile, kufanele kwenzeke:

· Yehlisa idivayisi/okunamathiselwe phansi/okunamathiselwe;

· Ukwehliswa kweyunithi/okunamathiselwe emsebenzini kubonakala endaweni lapho umshayeli enza kusebenze isilawuli sokwehlisa:

· Ukuqeda ukucindezela okuyinsalela kusekethe ngayinye ye-hydraulic kanye ne-pneumatic yemishini yokusebenza/impahla yokufinyelela engase ibangele ubungozi.Izinhlinzeko zokwehlisa okunamathiselwe kanye nezindlela zokususa umfutho osalayo zingatholakala ngaphandle kwendawo yomshayeli futhi zizochazwa encwadini yokushayela.

-Ukunyakaza okungalawuleki

Ukunyakaza kwemishini nezinto zokusebenza noma okunamathiselwe ezindaweni ezigxilile, ngaphandle uma kusetshenziswa umshayeli, ngenxa yokushelela noma ukuhamba kancane (isb. okubangelwa ukuvuza) noma lapho ukunikezwa kwamandla kuphazamiseka, kuzolawulwa phakathi kwebanga elingadali ingozi. kubantu abadaluliwe.

-Izibonisi ezibonakalayo/amaphaneli okulawula, izinkomba nezimpawu

· Umshayeli kufanele akwazi ukubona izinkomba ezidingekayo zokusebenza okuvamile komshini endaweni yomshayeli, emini noma ebusuku.Ukukhanya kufanele kuncishiswe.

Izinkomba zokulawula ukusebenza okujwayelekile nokuphepha komshini kufanele zihambisane nezinhlinzeko ze-ISO 6011 mayelana nokuphepha kanye nezindaba ezihlobene.

· Izimpawu zemishini yokubonisa/yokulawula emshinini wokunyakazisa umhlaba zizothobelana nezinhlinzeko ze-ISO 6405-1 noma ze-S 6405-2, njengoba kusebenza.

- Imishini yokulawula yemishini yokugibela okungahloselwe ukuthi isetshenziswe phansi izohlinzekwa ngezindlela zokunciphisa amathuba okuphakamisa idivayisi yokulawula ukusuka phansi.

- Imishini okungeyona eyokugibela kufanele ifakwe isisetshenziswa esibambayo esimisa ukusebenza komshini kanye nokunyakaza okuyingozi kwethuluzi lapho umshayeli ekhipha ukulawula.Izilawuli kufanele zakhelwe ukucabangela ubungozi bokuhamba ngephutha komshini uya ku-opharetha.

03Ukuhlolwa kwe-Mechanical Excavator-ukuhlolwa kwesistimu yokuqondisa

- Isistimu yokuqondisa kufanele iqinisekise ukuthi indlela yokuqondisa iyahambisana nesiqondiso esihlosiwe esicaciswe kusoISO 10968.

- Imishini emboze ibhande eya phambili/ehlehla Uhlelo lokuqondisa lomshini ovalwe ngebhande ohamba ngesivinini esingaphezu kuka-20 km/h kufanele lube mnene.

04Ukuhlolwa kwe-Mechanical Excavator-ukuhlolwa kwesistimu ye-swing brake

Ama-excavators angama-mechanical kufanele afakwe ukusebenza kokushwiba kanye nezinhlelo zamabhuleki okupaka.

05Ukuhlolwa kwe-Mechanical Excavator-ukuphakamisa ukuhlolwa kwesistimu

- Ukulawula okuphoqelelwe (ukuphakamisa / phansi)

Isistimu yokuphakamisa ye-excavator yemishini kufanele ifakwe ibhuleki.Ibhuleki kufanele lisebenze ngokushesha ngemva kokukhulula isibambo noma i-pedal.Isistimu yokubhuleka kufanele isebenze ngokuzenzekelayo uma kwenzeka ukuphelelwa amandla noma ukwehla kokulawula okuphoqelelwe, futhi akufanele kuthinte ukuzinza komsebenzi we-excavator.Ukubhuleka Uhlelo kufanele lukwazi ukugcina umthwalo olinganiselwe oshiwo ku-4.8

-Ukusebenza kokuwa kwamahhala

Uhlelo lokuphakamisa i-excavator engumshini kufanele lufakwe ibhuleki futhi luzovulwa ngokushesha ngaphansi kwalezi zimo ezilandelayo:--Ukusebenza okuhambisanayo kwe-foot pedal;

Khulula insimbi yesandla.

Amabhuleki azoklanywa ukuze anikeze ukubhuleka okuqhubekayo komthwalo onyakazayo. Umhlahlandlela kufanele wakhelwe ukuvimbela intambo yocingo ukuthi ingavuki noma iwele ekulawuleni.

-Shintsha

Lapho usuka ekusebenzeni kokulawula okuphoqelekile ukuya ekusebenzeni kokwehla kwamahhala, akufanele kube khona ukwehla komthwalo.

-boom

I-boom ye-excavator engumshini kufanele ivikelwe ekubopheni kabusha esimweni sokuthulula kungazelelwe.I-boom kufanele ifakwe iswishi ekhawulelwe ukuze kugwenywe ukulayishwa okubuyela emuva.

Izixhumanisi (amabholithi) phakathi kwezingxenye ezihlukahlukene ze-boom kufanele zakhelwe ukuvumela ukufakwa nokususwa ngaphandle kwesidingo sokuthi abasebenzi bame ngaphansi kwe-boom.

-Intambo yocingo

Isici sokuphepha sentambo yocingo lwe-excavator kufanele inqunywe.

-Isigubhu sentambo yocingo kanye ne-wire rope pulley

· Ukwakhiwa kanye nokwakhiwa kwezigubhu zezintambo zocingo kanye namapulangwe ezintambo zocingo kufanele kuvimbele ukulimala kwentambo yocingo kanye nokushelela noma ukuhlukaniswa komhlahlandlela wezintambo zocingo.

· Isilinganiso sedayamitha yesigubhu sentambo yocingo nobubanzi bentambo yocingo kufanele okungenani sibe ngu-20:1.

· Isilinganiso sedayamitha yentambo yentambo yocingo nedayamitha yentambo elinganiswa emseleni wezintambo kufanele okungenani sibe ngu-22:1.Iziqondiso zemigqa yokudonsa, ama-pulleys kanye nezintambo ezisizayo azifakiwe.

· I-crimping rim, unqenqema lwesigubhu sewinji kufanele okungenani lube ngokuphindwe ka-1.5 ububanzi bentambo yocingo.

06Ukuhlolwa kwe-Mechanical Excavator-ukukhawulela ukuhlolwa kwedivayisi

-Layisha umkhawulo wesikhathi

Ezimweni zokuphatha impahla, isistimu yokuphakamisa kanye nesistimu yokuphakamisa i-boom kufanele ifakwe isinqamuli sesikhathi somthwalo ukugwema ukugcwala ngokweqile.Umkhawulo wesikhathi sokulayisha kufanele usethelwe kumthwalo olinganiselwe ocaciswe ku-4.8, ngokubekezelela okungu-10%.Ngemva kokusetshenziswa komkhawulo wesikhathi sokulayisha, isikhathi sokulayisha kufanele sincishiswe.4.7.2 Phakamisa ukushintsha komkhawulo.

Ezimweni zokuphatha impahla, ama-excavators angama-mechanical kufanele afakwe amaswishi anomkhawulo wokunyakaza kokuphakamisa.Ngemuva kokuthi iswishi yomkhawulo isicushiwe, i-boom kufanele ikwazi ukwehla.

-Limit switch for boom lift system

Isistimu yokuphakamisa i-boom ye-excavator engumshini kufanele ifakwe iswishi enomkhawulo ukuze kugwenywe ukulayishwa okuphambene kwe-boom.Ngemuva kokuthi iswishi yomkhawulo isicushiwe, i-boom kufanele ikwazi ukwehla.

07Ukuhlolwa kwe-Mechanical Excavator-ukuhlola ukuzinza

- Imishini enyakazisa umhlaba enamadivayisi asebenzayo kanye nezinamathiselo, okuhlanganisa izisetshenziswa ozikhethela zona, eziklanywe futhi zakhiwe zizohlinzeka ukuzinza okwanele ngaphansi kokugcinwa, ukuhlanganisa, ukuqaqa kanye nezimo zokusebenza zokuthutha ezishiwo umenzi ebhukwini lomshayeli.Amadivayisi asetshenziselwa ukukhulisa ukuzinza kwemishini yokunyakazisa umhlaba kumodi yokusebenza kufanele afakwe i-valve yokukhiya noma indlela eyodwa ukuze kubambe ipayipi lapho lisebenza khona uma lehluleka noma ligcwala uwoyela.

- Ibhakede le-dragline, umthamo wokusebenza we-excavator engumshini ekusebenzeni kwe-dragline uzoba mncane kokubili okulandelayo:

a) ama-75% omthwalo oginqikayo obaliwe P;

b) Umthamo omkhulu wokuphakamisa iwintshi.

Ukulinganisa umthamo webhakede lokudonsa kuzonqunywa umkhiqizi

- Ukubambana nefosholo

Umthamo wokusebenza we-excavator engumshini ekubambeni nasezimeni zefosholo kufanele ube mncane kokubili okulandelayo:

· Ngokusekelwe ku-66% wesibalo esibaliwe sokugumbuqela esingu-P;

· Umthamo omkhulu wokuphakamisa wewintshi.

Ukulinganiswa komthamo wefosholo kuzonqunywa ngokuhambisana ne-ISO 7546 futhi ukulinganiswa komthamo webhakede lokubamba kuzonqunywa umkhiqizi.

Isikhathi sokuthumela: Dec-19-2023