A sofa is a kind of multi-seat chair with upholstery.A backrest chair with springs or thick foam plastic, with armrests on both sides, is a kind of soft furniture.The inspection and test of sofa is very important.So how do you inspect the sofa?

1. The overall inspection standard of the sofa

(1) Design and appearance

The style and collocation of the design are determined by the designer, not controlled by the scope of the inspection personnel.So we mainly discuss the inspection standards for appearance.

1. After the hair is set up, check whether the combination of corners is regular, and touch the armrests and corners to see if there are empty corners and whether the sponge is elastic.

2 Strictly follow the size of the prenatal sample after confirmation.

3. Leather and cloth:

a. When the factory leather or cloth comes back, check whether its color, texture, softness, etc. meet the requirements.

b. The texture of the leather/cloth is confirmed to be the same, moderate in softness and hardness, not hard, and no odor.

c. The sofa leather is flat, full and elastic, without bumps and folds; the pattern of the fabric sofa fabric stitching should be complete, the fluff direction is the same, and there is no hair removal phenomenon.

d. Open a part of the leather with both hands to see if there are any subtle cracks. The leather or fabric has no fading, and there are no stains, oil stains and residues.

4. Color: The color of the product needs to be confirmed according to the sample, the overall color should be uniform, there is no color difference, and the color of different POS of the same ITEM should be the same.For brightly colored fabrics or leather materials, wipe the surface with a white towel a few times to see if there is any discoloration.

5. Turning: The turning style is meticulous, there are no obvious floating lines, the embedded lines should be smooth and straight, there are no exposed threads, the rounded corners are well-proportioned, the exposed nails are neatly arranged, there is no white, no gaps, the stitching is intact, and there are no cracks.The first layer should be placed on top of the second layer of skin.

6. The surface of the external wooden parts is exquisite and smooth, with no tree knots, scars, horizontal stubble, inverse lines, grooves and mechanical damage. There are no burrs when touched by hand, and the outside should be chamfered.The rounded corners, radians and lines should be symmetrical and uniform.It is straight and smooth, and there must be no knife marks or sand marks.

7. The external paint parts should be free of sticky paint and peeling, the surface should be kept bright, there should be no small spots such as dust, and the electroplating parts should be free of cracks, peeling and rust.

8. The packaging must be in good condition, the hardware package is complete, the packaging is not damaged, and the content of the feeding mark is correct and clear.

(2) Perception

1. Confirm the feeling of sitting on the sofa in the prenatal sample:

Sitting on the sofa in free fall, the body feels whether the sofa is elastic, not only according to the prenatal confirmation, but also to confirm whether it feels like sitting on the wooden frame.

2. Press the armrests and backrests of the sofa with your hands, the leather or fabric is moderately soft and hard, and there is no obvious wooden frame.

3. There should be no abnormal metal friction and impact sounds when pressing the seat surface and back with bare hands.

4. Exposed metal parts have no edge burrs, and the gap between the seat surface and the armrest or backrest is reached into the burr-free edge sofa with bare hands, so that no sharp metal objects penetrate out of the seat surface and back.

5. Touch the surface of the sofa with your hands for a long time to feel whether the fabric will irritate the skin, and observe whether the fabric used before and after the sofa is consistent.

(3) Durability

1. Wooden frame: Check whether the moisture content of the wood is high, whether the wood is regular and strong, and whether the wooden frame is stable.Whether the sponge inside is clean, dry and odorless.Check the matching pillow and touch the interlining and filling inside with your hands.

2. The functional chair needs to be checked whether its functions are complete.

3. Sofa feet: Whether the metal sofa feet have rust marks, whether the solder joints are loose, and whether the wooden sofa feet have cracks.

4. Hardware: The nail gun is neat and complete, the structure is firm, and there is no loosening and falling off.

5. Leather: wear-resistant.You can rub the leather surface with a coarse cloth to test its wear resistance.

2.The appearance inspection standards of finished sofas

(1) Product appearance requirements

1. After the sofa is set up, the overall shape is symmetrical from the left to the right, the connection between the various parts is coordinated, and the corners are arranged in a regular manner. There should be no empty corners when touching the armrests and corners. There are no objects in the cracks, and the foam should be highly resilient.;

2. The product strictly follows the size and color of the sample after confirmation;

3. The soft-surface embedded thread should be smooth and straight, the rounded corners are symmetrical, and there is no obvious floating thread, jumping needle or exposed thread.;

4. The symmetrical pattern of the splicing of the covered fabric should be complete; the direction of the fabric in the same part should be the same, and there should be no obvious color difference.;

5. The surface of the soft bread coating should be flat, full, elastic and uniform, and there should be no obvious wrinkles. Symmetrical craftsmanship wrinkles should be well-proportioned and clearly layered.;

6. The coated fabric should be free of damage, scratches, color stains, and oil stains.;

7. The exposed rivets should be arranged neatly, the spacing should be basically equal, and the rivets should not be significantly flattened or unpainted.;

8. The spacing of sewing stitches should be uniform, with no obvious floating threads, curved or exposed threads, off-thread, slits, and degumming.;

9. Press the armrests and backrests of the sofa with your hands. The leather or fabric is moderately soft and hard, and there is no obvious wooden frame.;

10. Three people, two people with the same seat, different seats require the same seat feeling, and the back cushions must also be the same (every sofa must be experienced);

11. When pressing the seat surface by hand, the spring shall not make noises such as impact and friction.

12. The packaging must be in good condition, the hardware package is complete, the packaging is not damaged, and the contents of the mark are correct and clear.;

13. Lift up the sofa to see if the bottom treatment is meticulous. The legs of the sofa must be straight, the surface treatment must be smooth, and the bottom of the legs must have non-slip mats.;

14. All labels are ordered as required (the required location and quantity are correct).

(2) Appearance requirements of paint film

1. The color of the parts of the same color should be similar;

2. No fading or fading phenomenon;

3. The coating should not be wrinkled, sticky or leaking paint.;

4. The coating should be flat, smooth, clear, no obvious particles, no obvious processing marks, scratches, white spots, bubbling, and bristles.

5. The surface of the product is painted evenly, and the phenomenon of thickening and thinning is not allowed.

6. The external paint parts should be free of sticky paint and peeling, the surface should be kept bright, and there should be no small spots such as dust.

(3) Appearance requirements of hardware accessories

1. The structure and size of each part should meet the requirements of drawings or samples;

2. There are no obvious burrs (less than 0.2mm), indentation, bumps and obvious warping deformation, the interface is flat and the spot welding is beautiful.;

3. There is no obvious color difference between the color and the model, and the color of the same visual board is uniform, without dark lines, pigmentation, and variegation.;

4. If there is a pattern font or LOGO on the surface, the pattern and font should be clear and correct, and the content should be complete; the position deviation is ±0.5mm

5. Rust is not allowed on the hardware surface or welding parts, and salt spray testing should be done when incoming materials.;

6. Children's products cannot use screws with any sharp heads.

(1) Processing frame

1. The frame of the sofa is the basic shape and main load bearing part of the sofa, and it is also the basis for making the sofa. Therefore, all sofa frames must not use rotten wood, broken, severely lacking materials or bark, stuttering, insect-eyed wooden squares.;

2. The length and width of the frame cutting size deviation should be controlled at ±1MM, and the thickness and size deviation should be controlled at ±.5MM;

3. The edges of the cutting material should not have appearance problems such as burrs, chipping, serrations, and waves.

4. Control the moisture content of parts and components not to exceed 8%

(2) Nail frame

1. The height and size of the long and short strips of the inner material of the frame should be unified to avoid uneven surfaces.;

2. Nailing should not have floating nails, virtual nails or leakage of nail heads, etc.;

3. The nails should be flattened to prevent leaking nails and exploding.;

4. The placement of wooden strips should be placed in strict accordance with the drawings.;

5. The structure is firm, the interface is tight, and the wooden square has no cracking, deformation, or distortion.;

6. The tilt angle of the back is the same, and the overall size deviation shall not exceed 3MM.;

7. The frame should be positioned at right angles and must not be tilted.

(3) Sewing

1. All sewing leather and fabric turning lines should be straight, the curvature is symmetrical, the embedding is smooth, and there is no skew or damage as a whole.;

2. All leather materials have a needle pitch of 2.5cm for 5-6 needles, and fabric fabrics have a needle pitch of 2.5cm for 6-7 needles.;

3. There is no disconnection, needle skipping, or surface knotting in the sewing parts of all fabrics and leather materials.;

4. The leather seam position is correct, and the texture error at the seam position of the fabric should not exceed 1-2 mm.;

5. The surface of all sewing is evenly pressed, the width is the same, and the suture should be consistent with the color of the main body.;

6. There are no floating lines, no jumpers, and no leakage of pinholes on the surface of the sewing after processing. The color of the thread matches the surface of the leather cloth, and the texture of the fabric is uniform and there is no skew.

(4) Cutting foam

1. Proofread the sponge model and density according to the product style requirements before cutting;

2. The section is vertical, the incision is flush, the beveled edges, and the cutting edges shall not have serious waves.;

3. The size is accurate, the limit deviation of length and width is ≤±2MM;

4. The seam of the product with the edge should not be cracked, and the sponge should not exceed the outer skin too much, and the nailing position should not be too high.;

5. The radians are consistent with the radians required by the drawings.

(5) Spray glue

1. Choose standard environmentally friendly formaldehyde-free spray glue;

2. The glue requires uniform spraying, in place, and no leakage.;

3. Whether the sponge paste is flat and has no folds;

4. Whether the sponge paste is distorted and displaced.

(6) The skin of the child

1. The armrests, screens, and seats of the same product are the same in size, size, height, and lowness, and the seat corners and screen corners are the same in fullness. The screen lines are aligned with the seat lines, and the joints are compact.;

2. Observe the front and back from behind, and observe the seat surface in the same horizontal plane as the seat surface in front of the seat. The irregularities should be uniform.;

3. No floating nails, virtual nails and broken nails;

4. The seam of the back fabric is aligned with the seam of the screen fabric, the edges should be straight, the back of the screen neck should be full and not wrinkled.;

5. Where the bottom cloth is covered, the excess sponge and spray cotton should be cut off.;

6. The nails should be in a straight line, and the distance between the nails is about 2cm.;

7. Keep the bottom surface flat, do not expose nails or break nails, and do not hurt your hands by touching them with your hands.

(7) Labeling

1. The labeling content cannot be wrong or vague;

2. There must be a product qualification label on the product;

3. The digital or letter labels of the parts cannot be missed or misplaced.;

4. The product should have warning labels (such as careful and light labels, fragile labels, moisture-proof labels, etc.).

(8) Accessory package

1. The specifications of the accessories are correct and consistent with actual needs;

2. Different specifications of hardware cannot be mixed and packaged (such as metric and imperial);

3. Hardware accessories cannot be rusty or smudged;

4. Wooden accessories must not have moths or mold;

5. Accessories cannot be missed or overplayed.;

(9) Instruction manual

1. The manual should be clear and easy to understand, so that customers can assemble the product in accordance with the manual, and there should be explosion diagrams on the instructions for some key parts of the assembly.;

2. The hardware, language, component size, etc. on the manual are consistent with the information.;

3. The manual cannot be printed with missing pages, heavy pages, or damaged.

4. Product safety testing requirements for sofas

(1) Fabric testing requirements

1. Leather: The total lead content of all surface coatings is less than 40PPM, the total lead content of the heavy metal content of the underlying material is less than 100PPM, and the soluble lead content of the underlying material is less than 90PPM.;

2. Tensile test of leather/fabric: Randomly take not less than 5 pieces (divided into warp and weft) and cut them into 3*4-inch samples. The tensile test of each piece should be greater than 50lbs.;

3. Leather/fabric color fastness test: dry friction ≥4.0, wet friction ≥3.0;

4. Leather/fabric wear resistance test: The H-18 grinding wheel is 300 revolutions, the fabric cannot be worn through, and the loss is <10%;

5. Seam strength test: The seam strength should be ≥30lbs.

(2) Foam test

1. Foam fire resistance test: the sampling size is 12*4*0.5 inches in length, width and height, and 10 samples, 5 of which are aged for 24 hours; then ignite and burn for 12s, the flame height is 0.75 inches, and the length of the foam burned after burning is recorded. The combustion length of a single sample is <8 inches, and the average combustion length of 10 samples is <6 inches.;

2. Foam smoke-proof test: It is suitable for testing the flame-retardant properties of upholstered furniture materials with lighted cigarettes as the source of fire. The weight loss after the smoke-proof test cannot be ≥80%.

(3) Hardware testing

1. Screw strength test: the tensile strength of the M6 screw is ≥1100lbs, and the tensile strength of the M8 screw is ≥1700lbs.;

2. Salt spray test:

Use a salt spray tester with a concentration of 1% salt water, a constant temperature of 27 degrees Celsius and a humidity of 70%-80%. Spray for 24 hours. After the spray is over, gently rinse the surface of the sample with water. After drying, the surface should not have obvious rust spots, corrosion and other phenomena.

(4) Paint

1. The lead content of all accessible surface paints is ≤90PPM;

2. The surface of the sample paint must pass the hundred grid test, and there must be no paint loss.

3. The paint film is resistant to heat and humidity, 20min, 70℃.Should not be lower than level 3

(5) Stability test

1. Front stability: Put the single-seat sofa on the horizontal ground. For those with adjustable functions, the seat should be adjusted to the most unstable state. Place a wooden bar at the support foot in the test direction to prevent side slippage when horizontal tension is applied. The height of the wooden bar should be as low as 1 inch to avoid preventing the sample from tipping over; fixed point: First find the center point of the width of the cushion to make a mark, and then find the 2.4-inch position at the front end of the cushion to make a mark, and apply a force of 173lbs vertically downwards where the two points meet, and then apply a 4 horizontally forward. The tensile force of 5lbs, the judgment condition: During the entire test process, the product does not overturn, which is considered to have passed the test.;

2. Rear stability test: Use the standard 13 discs for stability after the test to pile up in turn and close to the backrest. After all the 13 discs are stacked, the rear seat will be qualified if there is no overturning phenomenon.

(6) Armrest strength test

1. Vertical strength test of armrests: This test is aimed at sofa seats with armrests. Fix the sofa seats on the test platform, restrict their free movement, adjust various functions to normal use conditions, and apply a force of 200lbs vertically down to the weakest part of the armrest (installed on the armrest with a 5-inch long device) for one minute, and then remove the force to check that the sofa cannot be damaged. Do another verification test, and apply a force of 300lbs vertically down to the weakest part for one minute. The unloading force can allow the product to lose some functions. But there can be no major structural changes.

2. Horizontal strength test of armrests: Fix the sofa seat on the test platform to prevent the chair from moving horizontally and overturning, but not to limit the activity of the armrests, adjust the functions to normal conditions of use, and apply a force of 100lbs horizontally in the weakest position of the armrests (with a device 1 inch wide mounted on the armrests) for one minute, and then remove the force to check, the product cannot have any loss of function or any damage, and then do a verification test, also apply a force of 150lbs horizontally in the weakest position for one minute, and then remove the force to check, the product allows Some functions are lost but no major structural changes can occur.

(7) Dynamic impact test

1. Place the sofa on the test platform and use a 225lbs sandbag to fall freely from a position 6 inches away from the height of the cushion. The sandbag cannot touch the back of the sofa during the fall. Then remove the sandbag and check that the product cannot have any loss of function or structural damage. Then do a verification test, use a 300lbs sandbag to fall freely from a position 6 inches away from the height of the cushion, and then remove the sandbag and check that the product is allowed to have some functional damage, but no major structural changes can occur.

(8) Sofa foot strength test

1. Select one of the sofa feet for testing, and apply a force of 75lbs to the front, back, and left directions of the sofa feet for one minute, so that the sofa feet cannot loose and fall off.

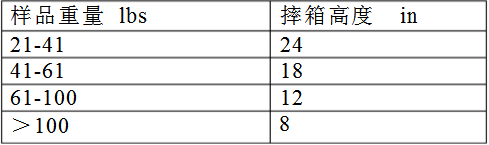

(9) Drop box test

1. Drop box requirements: one point, three sides and six sides;

2、

5. Product packaging inspection standards and requirements for sofas

(1) Outer packaging

1. The size, tile type, tile direction, color label, LOGO, and paper number must be consistent with the order information requirements.;

2. The contents of the outer box mark are consistent with the mark information;

3. There can be no obvious color difference between the cartons of the same batch.;

4. There must be no damage or smudges on the outside of the carton.;

5. The viscose at the joint and the nailing of the wooden frame should be firm.

(2) Inner packaging

1. The various parts in the package should be wrapped with pearl cotton or bubble film, and the gaps should be filled with fillers to prevent shaking.;

2. Confirm whether all labels, tags, hardware accessories, etc. are correct;

3. The non-woven fabric cover must cover all the sofas.;

4. Wrap the sofa tightly in a plastic bag and wrap the sofa with scotch tape. Pay attention to the cleanliness of the tape.

Post time: Apr-17-2024