When it comes to scales, everyone will not feel unfamiliar. They are very practical in measuring weight in daily life. Common types of scales include electronic kitchen scales, electronic body scales, and mechanical body scales. So, what are the key contents that need to be inspected and what tests need to be conducted when inspecting goods? We hope these contents are helpful to you!

Working principle

When an object is placed on the scale, pressure is applied to the sensor, which deforms, causing a change in impedance. At the same time, the excitation voltage is used to change and output a simulated signal of change. The signal is amplified by an amplification circuit and output to an analog-to-digital converter. Convert into easily processed digital signals and output them to the CPU for operational control. The CPU outputs this result to the monitor based on keyboard commands and programs. Until this result is displayed.

Classification of scales

In the inspection process, we mainly use electronic kitchen scales, electronic body scales, and mechanical body scales

Main components

1) Weight sensor 2) amplifier circuit 3) filter circuit 4) analog-to-digital converter 5) central processing unit 6) power supply circuit 7) buttons 8) housing 9) mechanism 10) scale

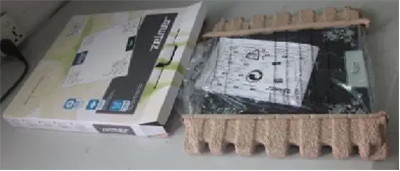

(1) Inspection of outer/inner boxes

(2) Color box/blister packaging inspection

(3) Inspection of accessories and other items

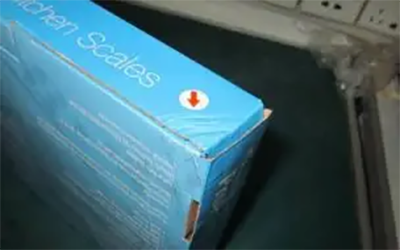

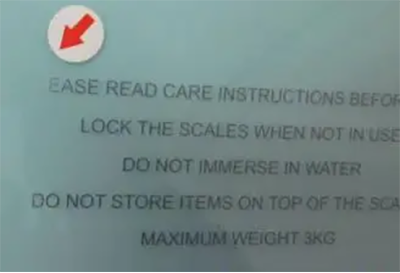

(4) Is the content on the packaging materials, including instructions, warranty cards, service cards, etc., consistent with the product

(1) Are there sharp edges and points, and is the battery leaking liquid

(1) Product confirmation inspection

Check if the product, including accessories, is consistent with the customer’s provided samples, specifications, orders, color box images and content, instructions, etc.

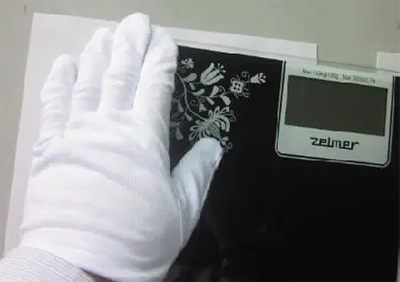

(2) Visual inspection

(1) Check with a handheld camera: Check for any foreign objects or loose assembly inside the product

(2) Assembly inspection: Check if there are too large gaps in the assembly of each part of the accessories, if the accessories are installed incorrectly, or if the accessories are too loose or tight.

(3) Battery box and battery door inspection: After installing the battery, cover the battery door and pat the machine with your hand. The product should not malfunction. (If the battery is installed inside the product and the customer requests a protective film for insulation, we need to check if this film can provide insulation protection.)

(4) Use a feeler gauge to check if the foot pads are uneven

Place the product on glass to see if it shakes, use a feeler gauge to measure its value and record it

5) Routine functional inspection

(1) On/Off switch 3 times, the product should have its original functions

(2) Accuracy testing

a. Generally, three weights are weighed (if requested by the customer, according to the customer’s requirements; if not, three points of 10%, 50%, and 90% of the maximum weight are generally required to be weighed)

b. Accuracy requirements (if requested by the customer, according to the customer’s requirements. If not, the kitchen scale is generally required to be+/-0. 5%, and the human scale should be ± 1%)

(2) LCD display function inspection (all strokes must be able to be displayed without missing strokes, etc.)

(4) Various switches should function normally

(5) Display the weight of the scale and check the automatic shutdown function

(6) Inspection of weight unit selection switches (Kg, Oz, Lb, etc.)

(7) Skin removal function inspection (applicable to kitchen scales)

Place 1KG weight code on the product and press the “Zero” button,

The product should display ’0′. Then add the code,

The product should display the weight of the subsequent addition code (i.e., the weight after peeling)

(8) Overweight function indicator inspection

(According to the instructions, if an overweight code is placed on the product, the LCD of the product should display overweight.)

(9) Check the function of the ’0′ adjustment knob (applicable to mechanical body scales)

(Adjust the ’0′ knob, the pointer should be able to indicate ’0′ and the knob should not have any jamming or other adverse phenomena)

(10) Automatic ’0′ reset function check (applicable to mechanical body scales)

(Remove the weight from the product, the product pointer should return to the ’0′ position, and there should be no jamming or other adverse phenomena on the pointer)

(11) Other functional requirements mentioned in the manual require inspection

6) Special data and measurement items

(1) Security aspect: None

(2) Performance testing

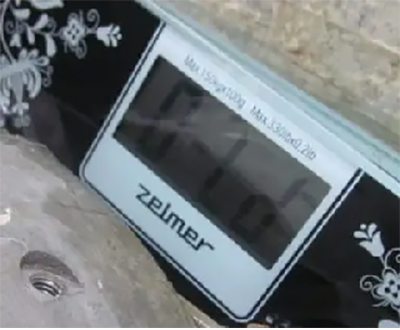

a. Battery voltage measurement

Use a multimeter to check that the battery voltage should exceed the nominal voltage

b. Standby current test

Check the standby current with a multimeter and record the parameters.

(Connect the multimeter in series to the product power supply circuit, and the standby current is the current when the product is turned on and not operated)

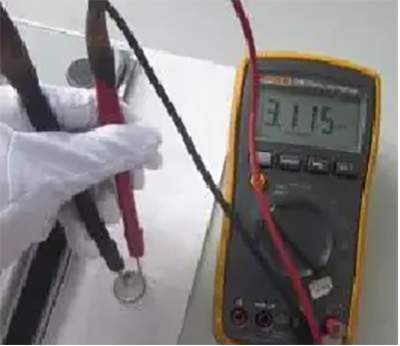

c. Low voltage display function inspection

(Low voltage display should be consistent with customer standards or instructions)

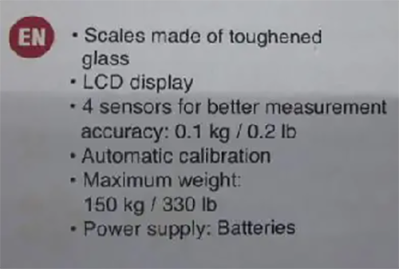

d. Maximum weighing range inspection

(The maximum weighing range should be consistent with the customer’s standard, color box, and instruction manual)

e. Resolution check

(The product resolution should be consistent with customer standards, color boxes, and instructions)

f. Repeated weighing error check

(Weigh 50% of the nominal maximum weight at the same position of the product three times, and record the change in weight three times. The resolution unit should not exceed 1 grid.)

g. Single or double foot weighing error check (applicable to human scale)

(Weighing on product with one or two feet – select a weight close to full weight and compare the changes in weighing, which should not exceed 1 grid resolution unit)

h. Internal process and major component inspection

(3) Dimensional inspection

a. Barcode scanning inspection

Scan the barcode three times with a scanner

The barcode must be readable and the number displayed by the scanner should match the number printed on the barcode.

b. Inspection of dimensions and weight of shipping cartons

Measure the length x width x height of the product or compare it with the product specifications. If no product specifications are provided, record the data in the report.

c. Measurement of product external dimensions

If the product or packaging size is not mentioned in the customer’s specifications, then this test is not suitable.

d. Transportation testing

(a) Shipping cardboard box drop test (if not requested by the customer, this test is not suitable).

1. Poor printing of the outer box and microphone

2. Wrinkles on the corners of the color box

3. Poor printing of the word ‘PLEASE’ on the plastic bag

4. There is dirt inside the mirror, with a diameter of 0.3mm

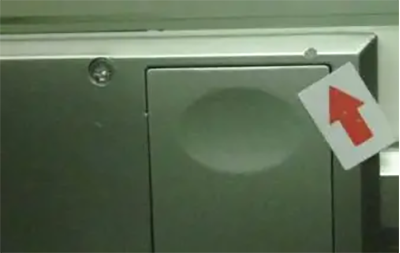

5. There are dents on the back of the product shell, with a diameter of 1.5mm

6. Scratches on the surface of the bowl (length 15mm)

7. The gong thread is not tightened tightly

Post time: Apr-11-2024