Showers are bathroom products that we need to use every day in our daily lives. Showers can generally be divided into two types: hand-held showers and fixed showers. How to inspect the shower head? What are the inspection standards for showerheads? What are the appearance inspection standards for shower products?

Visual inspection at a distance of 600 mm±50 mm from the shower head under the lighting conditions of 3001x20 1x

1.The outer surface of copper castings should not have defects such as shrinkage cavities, blisters, cracks and pores, and the inner cavity should not have molding sand adhering to it;

2.The outer surface of plastic parts should not have obvious defects such as ripples, scratches, modification damage, etc.;

3.All surfaces that can be touched by the human body during use should not have sharp corners or other hidden dangers that may cause harm to the human body.

4.After installation, there should be no unplated areas on the electroplated surface. The surface should be bright and even, and no peeling, peeling, blistering, etc. are allowed.

Physical and chemical performance testing

1. Pipe thread accuracy inspection

The pipe thread accuracy of the external connection of the shower head should be measured with a thread gauge of corresponding accuracy. The pipe thread accuracy of the external connection of the shower head should meet the relevant accuracy requirements.

2.Safety performance inspection

- Install the shower head in use state. After the water temperature is 42 C2C, the dynamic pressure is 0.10 MPa0.02 MPa and the dynamic pressure is 0.30 MPa±0.02 MPa. After stable use for 10 minutes and 10 seconds, check whether all parts of the shower head are in good condition by hand. Flexible, check the shower head, each component of the shower head should be flexible, the shower head should have no obvious deformation, and its water jet pattern should not change.

- Install the shower head in use state, with the water temperature at 70 C ± 2 C, dynamic pressure 0.05 MPa 0.02 MPa and dynamic pressure 0.50 MPa ± 0.02 MPa respectively. After stable use for 10 minutes and 10 s, check the various features of the shower head by hand. Check whether the parts are flexible. Check the shower head. Each part of the shower head should be flexible, the shower head should have no obvious deformation, and its water jet pattern should not change.

3.Surface coating and plating quality

- Rapid cooling and rapid heating performance test

The testing steps for quality requirements for surface coating and plating of plastic parts are as follows:

a) Place the sample in an oven with a temperature of 70°C ± 2C and keep it for 30 minutes;

b) Immediately place the sample at a temperature of 15C~20C for 15 minutes;

c) Immediately place the sample at a temperature of -30C~-25C for 30 minutes;

d) Immediately place the sample at a temperature of 15C~20C for 15 minutes.

The above is a rapid cooling and rapid heating test cycle, and the test is carried out accordingly, for a total of 5 cycles. After the cycle test, visually inspect whether the surface coating of the sample is damaged under a scattered light source of 700 1x~1 000 x intensity at a distance of 300 mm and 20 mm from the sample.

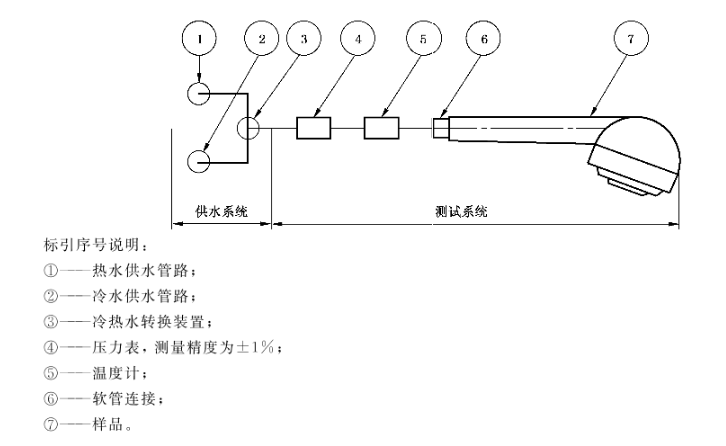

4.Sealing performance inspection

Connect the sample to the water supply pipeline. The water supply temperature is 70°C ± 2°C. The test dynamic pressure is 0.05 MPa ± 0.02 MPa and 0.50 MPa ± 0.02 MPa for 5 minutes ± 10 s respectively. Check whether there is any leakage between the shower head and its connecting parts. Water seepage phenomenon.

5.Mechanical strength inspection

There should be no cracks, visible permanent deformation or other damage after inspection.

6.Hot and cold fatigue resistance performance test

The water supply temperature at the hot water end is 70 C2, the water supply temperature at the cold water end is 20 C2, and the water supply flow rate is 0.30 MPa ± 0.02 MPa. When conducting the test at the maximum flow gear and the conversion time does not exceed 2 s, 2 n cold water is supplied first, and then 2 min hot water, for one cycle, conduct 300 cycle tests. After inspection, there should be no leaks, cracks, visible permanent deformations and functional failures.

7.Flow inspection

The test water supply temperature T<30C, the test has the following steps

- Adjust the test device at a dynamic pressure of 0.10 MPa ± 0.02 MPa, keep the pressure stable for 1 minute, and then record the flow rate q1. Keep the status of the test device unchanged and turn off the water supply.

- Install the sample on the test device, start the water supply, adjust the test dynamic pressure to 0.10 MPa ± 0.02 MPa, keep the pressure stable for 1 minute, test and record the flow rate of the shower head; test 3 times, and take the arithmetic mean Q1.

| style | the flow rate |

| hand shower | ≤7.5 |

| Fixed shower head | ≤9.0 |

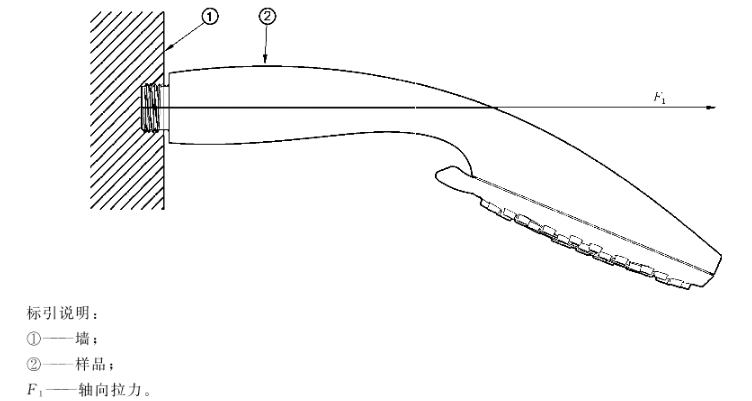

8.Tensile performance inspection

Install and fix the shower water inlet with the matching connecting device thread, apply an axial pulling force F of 500 N10 N to the shower head, and maintain it for 15 s5. Check whether there is any obvious damage to the shower handle, shower head, etc. at each connection part. Remove the shower head and connect it to the water supply pipeline. Keep it for 5 minutes ± 5 s under the conditions of water supply temperature not higher than 30C and dynamic pressure of .50 MPa0.02 MP. Check whether there is leakage in the shower head and its connecting parts. .

9.Resistance to installation load inspection

The shower connection pipe thread resistance to installation load shall be tested in accordance with regulations. After the test, the thread shall have no cracks, no damage and meet the requirements in the table below.

|

style |

Connection thread type | torsional moment |

| hand shower | Plastic/Metal Connector | ≥5 |

| Fixed shower head | Plastic connector | ≥5 |

| metal connector |

≥20 |

10.Cooling test

It is stipulated that the temperature drop should not be greater than 3C during the test.

11.Shower function conversion life test

This test should be carried out for showers with 2 or more water jets. After 10,000 cycles as specified, the requirements should be met.

12.Hand-held shower anti-siphon inspection

In the shower system, if the connecting parts other than the hand-held shower head, such as hoses and faucets, do not have anti-siphon devices, the hand-held shower head should have anti-siphon function. The anti-siphonage performance is tested in accordance with regulations, and there is no visible water level in the open pipe.

13.Swing performance test of spherical connection

For movable fixed showers or shower heads with ball connections, this test should be carried out. After 10,000 cycles in accordance with the regulations, the ball connection parts should have no leakage and should meet the requirements.

14.Function switching force test

For a multi-functional shower head, connect the sample to the water supply pipeline under the conditions of water supply temperature T≤30° and dynamic pressure 0.25 MP±0.02 MPa, and use the thrust meter test function to switch the force value at the end of the handle. Its function switching force or torque should not be greater than 45 or 1.7 N·m; for products designed for the disabled, before and after life testing, it should not be greater than 22 N.

15.Ball head swing power test

For movable fixed showers with ball connections, the ball head swing force is required to be tested and should not exceed 45N.

16.Drop test

Handheld showerheads are tested in accordance with regulations, and no deformation or cracks that affect safety and normal operation are allowed. Parts that become separated or fall off during the test can be reinstalled and the sample should maintain normal functionality. After the test, the hand shower should comply with the requirements.

17.Injection force inspection

When tested in accordance with regulations, the average spray force of the handheld shower should not be less than 0.85 N. If the flower wine contained in it has multiple ways of discharging water, the maximum average spray force will be used.

Post time: Jan-25-2024