Amashawa yimikhiqizo yokugezela okudingeka siyisebenzise nsuku zonke ekuphileni kwethu kwansuku zonke.Izihlambi ngokuvamile zingahlukaniswa zibe izinhlobo ezimbili: izihlambi eziphathwa ngesandla kanye nezihlambi ezihleliwe.Indlela yokuhlola ikhanda lokugeza?Yini iziamazinga wokuhlolangamakhanda eshawa?Ziyini ukubonakalaamazinga wokuhlolangemikhiqizo yokugeza?

Ukuhlolwa kokubukeka komkhiqizo

Ukuhlolwa okubonakalayo ebangeni elingama-600 mm±50 mm ukusuka ekhanda leshawa ngaphansi kwezimo zokukhanyisa ze-3001x20 1x

1.Ingaphandle le-copper castings akufanele libe namaphutha njengemigodi enciphayo, amabhamuza, imifantu nezimbotshana, futhi ingaphakathi akufanele libe nesihlabathi esibumbayo esinamathela kuso;

I-2.Indawo yangaphandle yezingxenye zepulasitiki akufanele ibe namaphutha asobala njengama-ripples, ama-scratches, umonakalo wokuguqulwa, njll.;

3.Zonke izindawo ezingathintwa umzimba womuntu ngesikhathi sokusetshenziswa akufanele zibe namakhona abukhali noma ezinye izingozi ezicashile ezingase zidale ukulimala emzimbeni womuntu.

4.Ngemva kokufakwa, akufanele kube nezindawo ezingahlanganisiwe endaweni ye-electroplated.Ubuso kufanele bukhanye futhi bulingane, futhi akukho ukuxebuka, ukuxebuka, amabhamuza, njll.

Ukuhlolwa kokusebenza komzimba namakhemikhali

1. Ukuhlolwa kokunemba kwentambo yepayipi

Ukunemba kwentambo yepayipi yokuxhumana kwangaphandle kwekhanda lokugeza kufanele kulinganiswe nge-gauge yentambo yokunemba okuhambisanayo.Ukunemba kwentambo yepayipi yokuxhumeka kwangaphandle kwekhanda lokugeza kufanele kuhlangabezane nezidingo zokunemba ezifanele.

2.Ukuhlolwa kokusebenza kokuphepha

- Faka ikhanda leshawa esimweni sokusebenza.Ngemuva kokuthi izinga lokushisa kwamanzi liyi-42 C2C, ingcindezi eguquguqukayo ingu-0.10 MPa0.02 MPa futhi ingcindezi eguquguqukayo ingu-0.30 MPa± 0.02 MPa.Ngemuva kokusetshenziswa okuzinzile imizuzu eyi-10 nemizuzwana eyi-10, hlola ukuthi zonke izingxenye zekhanda lokugeza zisesimweni esihle yini ngesandla.I-Flexible, hlola ikhanda lokugeza, ingxenye ngayinye yekhanda lokugeza kufanele ibe nezimo, ikhanda lokugeza akufanele libe ne-deformation ecacile, futhi iphethini yayo yejethi yamanzi akufanele ishintshe.

- Faka ikhanda leshawa esimweni esisetshenziswayo, nezinga lokushisa lamanzi liku-70 C ± 2 C, ingcindezi eguquguqukayo engu-0.05 MPa 0.02 MPa kanye nomfutho oguquguqukayo ongu-0.50 MPa ± 0.02 MPa ngokulandelanayo.Ngemuva kokusetshenziswa okuzinzile kwemizuzu eyi-10 nemizuzu eyi-10, hlola izici ezahlukahlukene zekhanda lokugeza ngesandla.Hlola ukuthi izingxenye ziyagobeka yini.Bheka ikhanda leshawa.Ingxenye ngayinye yekhanda lokugeza kufanele ibe nezimo, ikhanda lokugeza akufanele libe ne-deformation ecacile, futhi iphethini yayo yejethi yamanzi akufanele ishintshe.

I-3.I-Surface coating kanye nekhwalithi yokucwenga

- Ukupholisa okusheshayo nokuhlolwa kokusebenza kokushisa okusheshayo

Izinyathelo zokuhlola izidingo zekhwalithi zokumbozwa komhlaba kanye nokucwecwa kwezingxenye zepulasitiki zimi kanje:

a) Faka isampula kuhhavini onezinga lokushisa elingu-70°C ± 2C bese uyigcina imizuzu engama-30;

b) Ngokushesha beka isampula ekushiseni kuka-15C~20C imizuzu engu-15;

c) Ngokushesha beka isampula ezingeni lokushisa -30C~-25C imizuzu engu-30;

d) Ngokushesha beka isampula ekushiseni kuka-15C~20C imizuzu engu-15.

Okungenhla ukupholisa okusheshayo nomjikelezo wokuhlola wokushisa osheshayo, futhi ukuhlolwa kwenziwa ngokufanele, ngengqikithi yemijikelezo emi-5.Ngemva kokuhlolwa komjikelezo, hlola ngokubukeka ukuthi ingabe ukunamathela okungaphezulu kwesampula konakele yini ngaphansi komthombo wokukhanya ohlakazekile ongu-700 1x~1 000 x ukuqina ebangeni elingu-300 mm no-20 mm ukusuka kusampula.

4.Ukuhlolwa kokusebenza kokuvala uphawu

Xhuma isampula epayipini lokuphakela amanzi.Izinga lokushisa lokuhlinzekwa kwamanzi lingama-70°C ± 2°C.Ingcindezi yokuhlola eguquguqukayo ingu-0.05 MPa ± 0.02 MPa kanye no-0.50 MPa ± 0.02 MPa imizuzu engu-5 ± 10 s ngokulandelana.Hlola ukuthi ingabe kukhona ukuvuza phakathi kwekhanda leshawa nezingxenye zalo zokuxhuma.Isenzo sokugeleza kwamanzi.

5.Ukuhlolwa kwamandla omshini

Akufanele kube nemifantu, ukuguqulwa okubonakalayo okuhlala njalo noma omunye umonakalo ngemva kokuhlolwa.

6.Ukuhlolwa kokusebenza kokukhathala okushisayo nokubandayo

Izinga lokushisa lokuphakelwa kwamanzi ekugcineni kwamanzi ashisayo liyi-70 C2, izinga lokushisa kwamanzi ekugcineni kwamanzi abandayo lingu-20 C2, futhi izinga lokugeleza kwamanzi liyi-0.30 MPa ± 0.02 MPa.Lapho uqhuba ukuhlolwa ku-gear flow gear esiphezulu futhi isikhathi sokuguqulwa asidluli i-2 s, 2 n amanzi abandayo anikezwa kuqala, bese kuthi 2 min amanzi ashisayo, ngomjikelezo owodwa, enze ukuhlolwa komjikelezo we-300.Ngemuva kokuhlolwa, akufanele kube khona ukuvuza, ukuqhekeka, ukukhubazeka okubonakalayo okuhlala njalo kanye nokwehluleka kokusebenza.

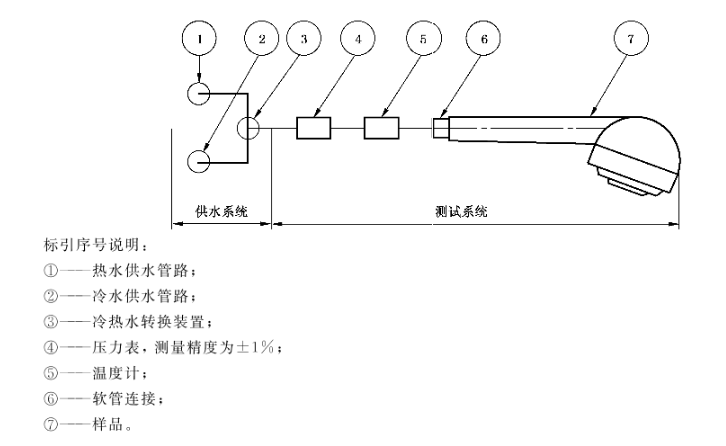

7.Ukuhlolwa kokugeleza

Izinga lokushisa lokuhlola amanzi T<30C, ukuhlolwa kunezinyathelo ezilandelayo

- Lungisa idivayisi yokuhlola ngengcindezi eguquguqukayo engu-0.10 MPa ± 0.02 MPa, gcina ukucindezela kuzinzile iminithi elingu-1, bese urekhoda izinga lokugeleza q1.Gcina isimo sedivayisi yokuhlola singashintshiwe bese uvala ukuhlinzekwa kwamanzi.

- Faka isampula kudivayisi yokuhlola, qala ukuhlinzekwa kwamanzi, lungisa ingcindezi yokuhlola eguquguqukayo ibe ngu-0.10 MPa ± 0.02 MPa, gcina ukucindezela kuzinzile umzuzu ongu-1, hlola futhi urekhode izinga lokugeleza kwekhanda lokugeza;hlola izikhathi ezi-3, bese uthatha i-arithmetic mean Q1.

| isitayela | izinga lokugeleza |

| ishawa yesandla | ≤7.5 |

| Ikhanda leshawa elilungisiwe | ≤9.0 |

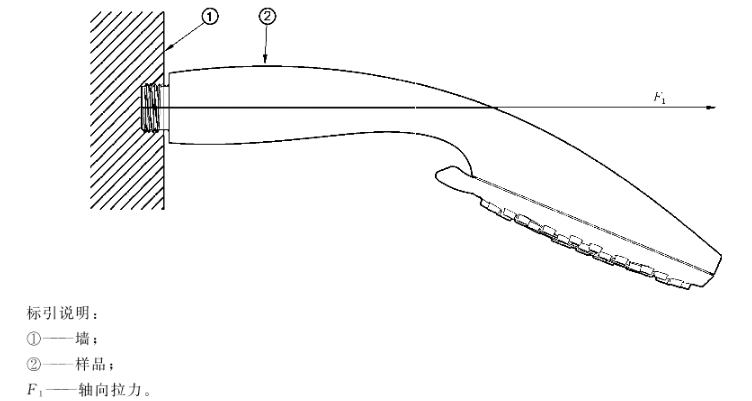

8.Ukuhlolwa kokusebenza okuqinile

Faka futhi ulungise indawo yokungena amanzi eshawa ngomucu wedivayisi oxhumayo, sebenzisa amandla okudonsa i-axial F ka-500 N10 N ekhanda leshawa, futhi uyigcine u-15 s5.Hlola ukuthi ingabe ukhona yini umonakalo osobala esibambo seshawa, ikhanda leshawa, njll. engxenyeni ngayinye yokuxhumana.Susa ikhanda leshawa bese ulixhuma epayipini lokuphakela amanzi.Yigcine imizuzu emi-5 ± 5 s ngaphansi kwezimo zokushisa kwamanzi ezingekho ngaphezu kuka-30C kanye nokucindezela okuguquguqukayo okungu-.50 MPa0.02 MP.Hlola ukuthi ingabe kukhona ukuvuza ekhanda leshawa kanye nezingxenye zayo zokuxhuma..

9.Ukumelana nokuhlolwa komthwalo wokufaka

Ukumelana nentambo yepayipi yokuxhumeka kweshawa kumthwalo wokufaka kuzohlolwa ngokuhambisana nemithethonqubo.Ngemuva kokuhlolwa, intambo ngeke ibe nokuqhekeka, akukho monakalo futhi ihlangabezane nezidingo etafuleni elingezansi.

| isitayela | Uhlobo lochungechunge lokuxhuma | umzuzu we-torsional |

| ishawa yesandla | Isixhumi sePlastiki/Metal | ≥5 |

| Ikhanda leshawa elilungisiwe | Isixhumi sePlastiki | ≥5 |

| isixhumi sensimbi | ≥20 |

10.Ukuhlolwa kokupholisa

Kubekwe ukuthi ukwehla kwezinga lokushisa akufanele kube ku-3C ngesikhathi sokuhlolwa.

11.Isivivinyo sempilo yokuguqulwa komsebenzi wokugeza

Lokhu kuhlolwa kufanele kwenzelwe izihlambi ezinamajethi amanzi ama-2 noma ngaphezulu.Ngemuva kwemijikelezo eyi-10,000 njengoba kucacisiwe, izimfuneko kufanele zihlangatshezwe.

I-12.Ukuhlolwa kwe-anti-siphon eshaweni ebanjwe ngesandla

Kuhlelo lokugeza, uma izingxenye zokuxhuma ngaphandle kwekhanda lokugeza elibanjwe ngesandla, njengama-hoses nama-faucets, zingenawo amadivaysi e-anti-siphon, ikhanda lokugeza elibanjwe ngesandla kufanele libe nomsebenzi wokulwa nesiphon.Ukusebenza kwe-anti-siphonage kuhlolwa ngokuhambisana nemithethonqubo, futhi akukho izinga lamanzi elibonakalayo epayipini elivulekile.

13.Isivivinyo sokusebenza kwe-Swing sokuxhuma kwe-spherical

Kumashawa angaguquki agudlukayo noma amakhanda eshawa anoxhumo lwebhola, lokhu kuhlolwa kufanele kwenziwe.Ngemuva kwemijikelezo engu-10,000 ngokuhambisana nemithethonqubo, izingxenye zokuxhunywa kwebhola akufanele zibe nokuvuza futhi kufanele zihlangabezane nezidingo.

14.Ukuhlolwa kwamandla okushintsha umsebenzi

Ukuze uthole ikhanda leshawa elinemisebenzi eminingi, xhuma isampula epayipini lokuphakela amanzi ngaphansi kwezimo zezinga lokushisa lokuphakelwa kwamanzi elingu-T≤30° kanye nomfutho oguquguqukayo ongu-0.25 MP±0.02 MPa, bese usebenzisa umsebenzi wokuhlola imitha ye-thrust ukushintsha inani lamandla ekugcineni kwesibambo.Amandla okushintsha umsebenzi wawo noma i-torque akufanele ibe mkhulu kuno-45 noma 1.7 N·m;emikhiqizweni eyenzelwe abakhubazekile, ngaphambi nangemuva kokuhlolwa kwempilo, akufanele ibe ngaphezu kuka-22 N.

15.Ball head swing power test

Kumashawa angaguquki anyakazayo anoxhumo lwebhola, amandla okushwiba kwekhanda lebhola ayadingeka ukuthi ahlolwe futhi akufanele adlule ku-45N.

16.Drop test

Ama-showerheads aphathwa ngesandla ahlolwe ngokuhambisana nemithethonqubo, futhi akukho deformation noma imifantu ethinta ukuphepha nokusebenza okuvamile okuvunyelwe.Izingxenye ezihlukaniswayo noma eziwayo phakathi nokuhlolwa zingaphinda zifakwe futhi isampuli kufanele igcine ukusebenza okuvamile.Ngemuva kokuhlolwa, ishawa yesandla kufanele ihambisane nezidingo.

17.Ukuhlolwa kwamandla omjovo

Uma ihlolwa ngokuhambisana nemithethonqubo, amandla okufutha amaphakathi eshawa ephathwayo akumele abe ngaphansi kuka-0.85 N. Uma iwayini lembali eliqukethwe kulo linezindlela eziningi zokukhipha amanzi, kuzosetshenziswa amandla amakhulu okufafaza amaphakathi.

Isikhathi sokuthumela: Jan-25-2024