The inspection of accessories should be used in conjunction with the textile inspection guide. The accessories products in this issue include handbags, hats, belts, scarves, gloves, ties, wallets and key cases.

Main checkpoint

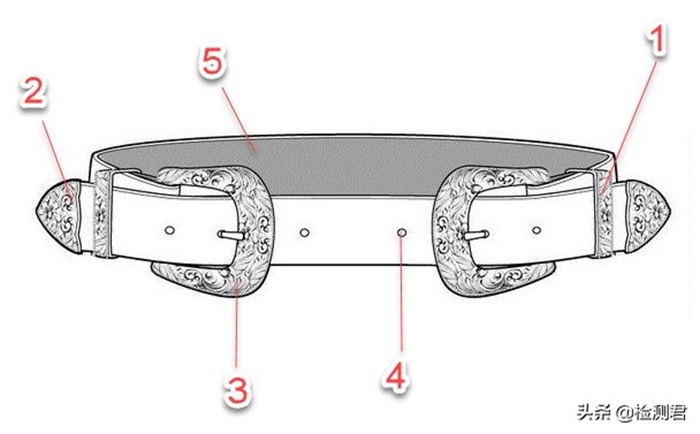

· Belt

Whether the length and width are as specified, whether the buckle and buckle holes match, all edges, material and workmanship quality, etc.

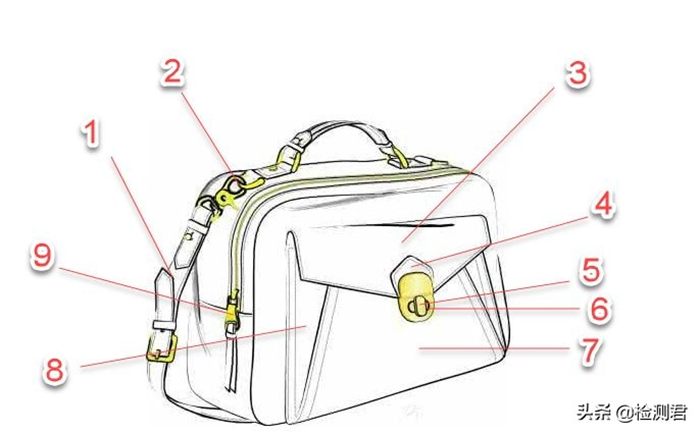

· Handbag

Shape, position and quality of logo, function, quality of materials and workmanship, etc.

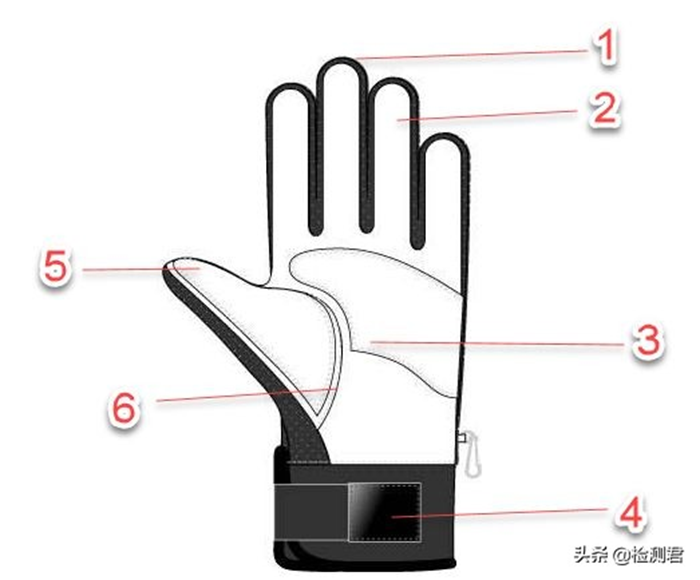

· Gloves

Compare the left and right parts of each pair of gloves (shape, design, texture, length and color difference), material and workmanship quality, etc.

Defect classification

1. Labeling, Marking, Printing (Sales Packaging and Products)

(1) Products sold in the European and American markets: no information on fiber content – major flaws

(2) Missing or wrong size information exported to the United States – major defects

Missing or incorrect size information for export to Europe – minor defect

(3) Products sold in the U.S. market: no country of origin information—major flaws

(4) Products sold in the US market: no manufacturer’s name/registration number (only applicable to textiles or products wrapped in textile fabrics) – major defects

2. Materials

(1) Mildew – fatal defect

(2) Damaged fabrics, sparse roads, color profiles, long missing needles, etc. – the main defects

(3) The hand feel is different from the customer’s signed sample or color sample – the main defect

(4) Inconsistent thickness caused by improper scraping – major or minor defects

(5) Insect bite marks – major or minor defects

(6) Plastic Defects – Piping (small burrs), unclear nozzle, insufficient filling (lack of material), embedded stains, pinch marks, flow marks, white spots, silver spots, needle marks, mold scratches – major or minor defect

(7) Texture mismatch – major or minor defects

(8) Leather frizz – major or minor defects

(9) Different textures – major or minor defects

3. Accessories (buttons, snaps, studs, rivets, zippers, buckles, hooks)

(1) Fractures, gaps – major or minor defects

(2) Improper bonding, lamination, welding or reinforcement/looseness – major or minor defects

(3) Deformed or broken fittings that do not meet the requirements – major or minor defects

(4) Unsmooth movement/functional impairment in movable places – major or minor defects

(5) loose fasteners – major or minor defects

4. Production process

(1) Embroidery

Bad shape or production of logo – major flaws

Poor quality of embroidery stitches – major or minor defects

(2) Printing

·The pattern does not meet the requirements – the main defect

· Pattern asymmetry – minor defects

(3) Cut

Crooked/Twisted Fabric Cuts – Minor Imperfections

(4) Suture

·Breaklines – major or minor defects

· Needlework – major or minor defects

· Seam loose (seam slippage) / burst / exposed bottom layer – major defects

·Punching hole / punching hole – main defect

5. Assembly

(1) There is a gap at the joint – a major or minor defect

(2) The fittings at the junction are unevenly arranged – major or minor defects

(3) Poor welding on the edge of the seam – major or minor defects

(4) The belt ring is too small to pass through – the main defect

(5) Dislocation of stripes/lattice/printing – the main defect

(6) The way of inserting the strips is wrong

6. Appearance

(1) Serious inconsistency/inconsistency in color, shape, printing and other materials – major defects

(2) Inconsistency/inconsistency in color, shape, printing and other materials – minor defects

(3) Uneven surface – major or minor defects

(4) The shape of the end of the belt is not good – the main defect

(5) Scratches, tooth marks, whitening, smudges, grit, dust, dirt, burn marks, glue marks visible at arm’s distance – major or minor defects

Field verification and testing (field verification may apply)

1. Textile size measurement

Number of samples:

Each size measurement sample is 4 pieces. For a single size product: The sample size for size measurement is Special Inspection Level 2 (S-2)

Inspection requirements:

Check against the requirements provided or the dimensional information on the product packaging material.

If the customer does not provide the tolerance, please use the tolerance of the trade point, and in the dimension measurement table of the report, change the “tolerance” to “the trade point tolerance”. If the number of dimension points exceeding the trade point tolerance is greater than 10% of the total number of points of the measured dimension, the inspection result is to be determined by the customer.

Unqualified Criteria:

If, for a single size, all measured samples are out of tolerance at one dimension point. Either the number of out-of-tolerance dimension points is greater than 10% of the total number of points of the measured dimension, or if, for a single size, the measured sample is increased and it is found that more than 50% of the samples are out of tolerance at a dimension point.

2. Product weight check:

(This check is only required if there is a product weight requirement or if the product weight information is displayed on the packaging material).

Number of samples:

The same number of samples as the product size measurement, use the same sample size for the weight check.

Inspection requirements:

Weigh the product and record the actual data, check against the weight requirements provided or the weight information and tolerances on the product packaging material. If the customer does not provide the tolerance, please refer to the tolerance of the trade point (-0, +5%) to determine the result.

Pass if all actual weighing results are within tolerance.

If any of the actual weighing results are out of tolerance, it is up to the customer to decide.

Post time: Aug-09-2022