Miyezo yovomerezeka ya dziko ndi IEC ili nayozofunikira zaukadaulopoyika chizindikiro, chitetezo choletsa kugwedezeka, kapangidwe kake, magwiridwe antchito amagetsi, magwiridwe antchito amakina, ndi zina zambiri zamapulagi ndi soketi zanyumba ndi zolinga zofanana.Zotsatirazi ndi miyezo yoyendera ndi njira zamapulagi ndi zitsulo.

Kuwunika kwa pulagi ndi socket

1. Kuyang'anira maonekedwe

2. Kuyang'ana mbali zonse

3. Chitetezo ku kugwedezeka kwamagetsi

4. Njira zoyatsira pansi

5. Ma Terminals ndi Headers

6. Mapangidwe a soketi

7. Kusakalamba komanso chinyezi

8. Insulation resistance ndi mphamvu zamagetsi

9. Kutentha kumakwera

10. Kuphwanya mphamvu

11. Opaleshoni yachibadwa (mayesero a moyo)

12. Mphamvu yokoka

13. Mphamvu zamakina

14. Kuyesa kukana kutentha

15. Zopangira, zida zonyamula pakali pano ndi kulumikizana kwake

16. Creepage mtunda, chilolezo magetsi, malowedwe kutchinjiriza kusindikiza mtunda

17. Kukana kutentha kwachilendo ndi kukana kwa moto kwa zipangizo zotetezera

18. Ntchito yolimbana ndi dzimbiri

1. Kuyang'anira maonekedwe

1.1 Zigawo zazikulu za mankhwalawa ziyenera kukhala ndi izi:

-Kuvotera panopa (amps)

- Mphamvu yamagetsi (volts)

- Chizindikiro chamagetsi;

-Dzina, chizindikiro kapena chizindikiritso cha wopanga kapena wogulitsa;

-Nambala yachinthu

- Chizindikiro

1.2 Zizindikiro zolondola ziyenera kugwiritsidwa ntchito pazogulitsa:

1.3 Pazitsulo zokhazikika, zizindikiro zotsatirazi ziyenera kulembedwa pazigawo zazikulu:

-Kuvotera pakali pano, voliyumu yamagetsi ndi mphamvu zamagetsi;

-Dzina kapena chizindikiro kapena chizindikiritso cha wopanga kapena wogulitsa;

-Kutalikirana kotsekera komwe kuyenera kuvula kondakitala asanalowetsedwe mu terminal yopanda screwless (ngati ilipo);

- Ngati soketiyo ili yoyenera kulumikiza mawaya olimba, payenera kukhala chizindikiro chakuti malo opanda screwless ndi oyenera kulumikiza mawaya olimba;

-Nambala yachitsanzo, yomwe ikhoza kukhala nambala yamakalata.

1.4 Kuwoneka bwino: Pamwamba pazitsulo ziyenera kukhala zosalala, chipolopolocho chiyenera kukhala chofanana, ndipo pasakhale pores, ming'alu, indentations, totupa, kuwonongeka, mawanga, kapena dothi;mbali zachitsulo siziyenera kukhala ndi okosijeni, mawanga a dzimbiri, mapindikidwe, dothi, ndi zokutira ziyenera kukhala zofanana komanso zowala.

1.5 Kupaka: Dzina lazinthu, mawonekedwe, nambala yazinthu, dzina la fakitale, kuchuluka, ndi nambala ya batch yopanga ziyenera kulembedwa pabokosi lonyamula.

2. Kuyang'ana mbali zonse

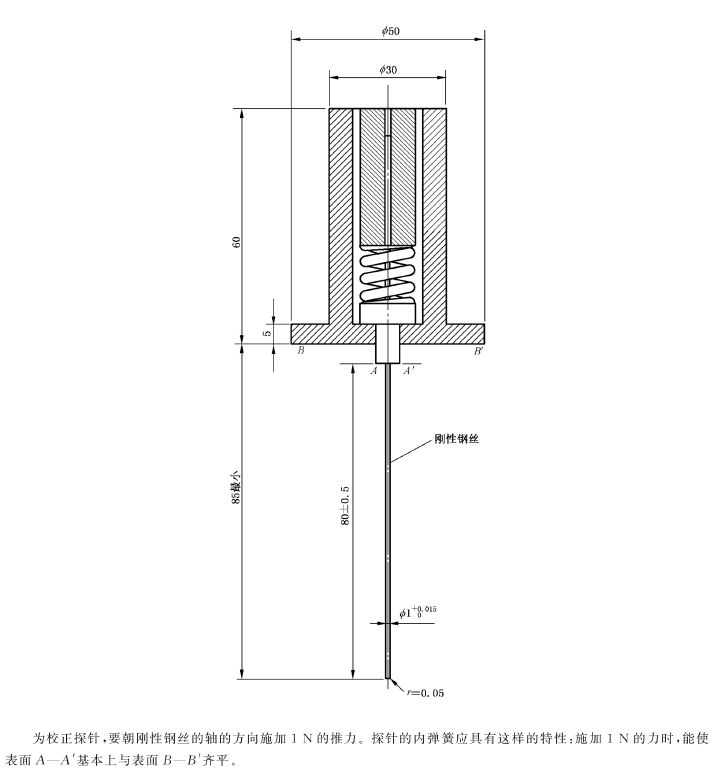

2.1 Soketi iyenera kulowetsedwa ndikumasulidwa ka 10 ndi pulagi yokhala ndi pini yayikulu kwambiri yomwe imakwaniritsa zofunikira za muyezo womwewo.Kukula kwa pini kumawunikiridwa poyezera kapena kugwiritsa ntchito geji.

2.2 Mu dongosolo lomwe laperekedwa, pulagi siyenera kulumikizana ndi socket-outlets:

-Masoketi okhala ndi ma voliyumu apamwamba kwambiri kapena kutsika kwapano;

-Masoketi okhala ndi ma electrode osiyanasiyana;

3.Pchitetezo motsutsana ndi kugwedezeka kwamagetsi

3.1 Pulagi ikalowetsedwa mu socket, mbali zamoyo za pulagi ziyenera kukhala zosafikirika.Yang'anani ngati ili yoyenera poyang'anira.Ma socket-outlets okhazikika, mapulagi ophatikizika ndi ma socket-outlets amamangidwa ndikupangidwa kuti, akayikidwa kapena wayaya kuti agwiritse ntchito bwino, mbali zamoyo sizipezeka ngakhale atachotsa mbali zomwe zimapezeka popanda zida.Zomwezo zimapitanso mbali zomwe zingathe kuchotsedwa.

3.2 Zida zamagetsi zikalumikizidwa ndi waya ndikuyikidwa molingana ndi zofunikira zomwe zimagwiritsidwa ntchito, zimakhalabe magawo ofikirika, kupatula zomangira zing'onozing'ono ndi zigawo zofanana zomwe zimagwiritsidwa ntchito kukonza zigawo zazikulu ndi zophimba ndi zophimba zazitsulo, zomwe zimasiyanitsidwa ndi moyo. magawo.Ayenera kupangidwa ndi zipangizo zotetezera.zakuthupi.

3.3 Pini iliyonse ya pulagi sidzatha kulumikiza ndi soketi ya soketi pamene pini ina ili yonse ikupezeka.

3.4 Zigawo zakunja za pulagi ziyenera kupangidwa ndi zinthu zotetezera.Izi siziphatikiza mbali zofikirako monga zomangira, mapini onyamula pakali pano, mapini oyambira pansi, zomangira, ndi mphete zachitsulo zozungulira mapini.

3.5 Socket yokhala ndi chitseko choteteza, pulagi ikatulutsidwa, socket yamoyo imatha kutetezedwa yokha.

3.6 Manja apansi a soketi asakhale opunduka m'njira yomwe ingawononge chitetezo chifukwa choyika pulagi.

3.7 Pazitsulo zokhala ndi chitetezo chowonjezereka, zikaikidwa ndi waya malinga ndi zofunikira zogwiritsira ntchito, zigawo zamoyo ziyenera kukhala zosafikirika ndi 1 mm m'mimba mwake.Monga momwe zilili pansipa:

4. Njira zoyatsira pansi

4.1 Pulagi ikalowetsedwa, pini yoyambira iyenera kulumikizidwa ndi socket yoyamba, ndiyeno pini yonyamula pakali pano iyenera kulimbikitsidwa.Pulagi ikachotsedwa, pini yonyamula pakali pano iyenera kudulidwa pini yapansi isanaduke.

4.2 - Kukula kwa terminal yapansi kudzakhala kofanana ndi kukula kwa terminal kokondakita yamagetsi.

- Malo opangira magetsi osinthika okhala ndi zolumikizira padziko lapansi azikhala mkati.

- Malo otsetsereka apansi a socket-outlet adzakhazikika pamunsi kapena pachigawo chokhazikika pamunsi.

- Dzanja loyambira la socket-outlet liyenera kukhazikika pamunsi kapena pachivundikiro.Ngati atayikidwa pachivundikirocho, dzanja lapansi lidzalumikizana ndi malo oyambira pomwe chivundikirocho chili pamalo ake onse.Zolumikizira ziyenera kukhala zokutidwa ndi siliva kapena zizikhala ndi dzimbiri komanso zosagwirizana ndi siliva.

4.3 Muzitsulo zokhazikika zokhala ndi zitsulo zoyambira pansi, zitsulo zofikirika zomwe zidzakhala zamoyo pamene kutchinjiriza kulephera ziyenera kulumikizidwa kosatha ndi kotetezedwa ku malo oyambira.

4.4 Socket-outlet yokhala ndi nambala ya IP yokwera kuposa IPXO komanso malo otsekera okhala ndi chingwe cholowera kuposa chimodzi chizikhala ndi malo otsekera mkati, kapena kupereka malo okwanira malo oyandama, kulola maulumikizidwe obwera ndi otuluka kuti zitsimikizire kupitiliza kwa kuzungulira pansi.

4.5 Kulumikizana pakati pa malo otsetsereka pansi ndi zitsulo zopezeka mosavuta kuyenera kukhala kugwirizana kochepa, ndipo kukana sikuyenera kukhala kwakukulu kuposa 0.05Ω.

4.6 Zotsekera zokhazikika zomwe zimapangidwira kuti zipereke dera lomwe silingasokonezedwe ndi magetsi pomwe zida zomwe zidalumikizidwa zizikhala ndi socket yoyambira ndipo ma terminals ake azikhala otalikirana ndi zitsulo zilizonse kapena kuchokera ku nthaka yoteteza yomwe ingakhale olumikizidwa ku dongosolo.magetsi otalikirana ndi mbali zina zowonekera za dera.

5.Materminals ndi mitu

5.1 Ma sockets okhazikika omwe amatha kubwezeredwa azikhala ndi ma terminals okhala ndi screw-clamp kapena ma terminals opanda screwless.

5.2 Mapulagi opangidwanso ndi ma socket-outlets otha kubwezanso azikhala ndi ma terminals okhala ndi ulusi wothirira.

5.3 Ngati zingwe zogulitsidwa kale zikugwiritsidwa ntchito, ziyenera kudziwika kuti muzitsulo zamtundu wa screw-type, malo omwe agulitsidwa kale ayenera kukhala kunja kwa malo otsekemera pamene akugwiritsidwa ntchito bwino.

5.4 Ngakhale magawo omwe amagwiritsidwa ntchito kukakamiza ma kondakitala mu terminal atha kugwiritsidwa ntchito kusungitsa ma terminal ali momwemo kapena kuletsa terminal kuti isazungulire, sayenera kugwiritsidwa ntchito kukonza zina zilizonse.

5.3 Thread clamp type terminal

-Magawo ophatikizika a ulusi ayenera kulumikiza makondakitala osasinthidwa;

- Malo otchingira ulusi akuyenera kukhala ndi mphamvu zokwanira zamakina ndipo asakhale ndi chitsulo chofewa kapena chitsulo chomwe chimakonda kukwawa;

- Ma terminal clamping ulusi ayenera kugonjetsedwa ndi dzimbiri;ulusi clamping terminals sayenera kuwononga kwambiri ma conductor powamanga;

-Malo otsekera okhala ndi ulusi amatha kumangirira kokondakita pakati pa zitsulo ziwiri;

-Terminal clamping terminal, mukamangitsa wononga kapena nati, ndizosatheka kuti mawaya a cokondakita olimba a single-core kapena kondakitala wokhazikika atuluke;

- Ma terminals amtundu wa ulusi azikhazikika mu pulagi ndi socket m'njira yoti zomangira zomangira kapena mtedza zisamangidwe kapena kumasulidwa popanda kupangitsa kuti terminal isungunuke.

- Zomangira zomangira ndi mtedza wa ma terminals amtundu wa ulusi wa clamp ziyenera kutsekedwa mokwanira kuti zisamasuke mwangozi;ndipo akuyenera kukhala opanda zida.

- Ma terminal amtundu wa Thread clamp adzakhala oti pasakhale chiwopsezo cha dzimbiri chifukwa cholumikizana pakati pa zigawozi ndi kondakitala yamkuwa kapena zitsulo zina zomwe zingakhudzidwe nazo.

5.4 Ma terminal opanda ma screw a ma conductor akunja amkuwa

- Ma terminal opanda ma screwless amatha kukhala amtundu woyenera okhawo opangira mkuwa wolimba, kapena amtundu woyenera makondakitala amkuwa olimba komanso ofewa.

- Ma terminal opanda screwless amatha kulumikiza ma conductor omwe sanakonzedwe mwapadera.

-Ma terminal opanda ulusi amayenera kutetezedwa bwino pa socket.Ma terminal opanda screwless sayenera kumasuka chifukwa cholumikizidwa kapena kulumikizidwa kwa ma conductor panthawi yoyika.

-Ma terminal opanda ulusi amatha kupirira zovuta zamakina zomwe zimachitika pakagwiritsidwe ntchito bwino.

-Ma terminal opanda ma Threadless amatha kupirira kupsinjika kwa magetsi ndi kutentha komwe kumachitika pakagwiritsidwe ntchito bwino.

6.1 Zigawo za mkono wa socket ziyenera kukhala zotanuka mokwanira kuti zitsimikizire kukhudzana kokwanira ndi zikhomo.

6.2 Zigawo za socket-outlet assembly zomwe zimagwirizana ndi zikhomo za pulagi ndipo zimagwiritsidwa ntchito kuti zigwirizane ndi magetsi pamene pulagi yalowetsedwa mu socket iyenera kuwonetsetsa kuti pali kukhudzana kwachitsulo kumbali ziwiri zosiyana. pin.

6.3 Dzanja la soketi liyenera kugonjetsedwa ndi dzimbiri komanso kuvala.

6.4 Zofunikira pazitsulo zotsekera ndi zotchingira zotchingira.

6.5 Socket-outlet idzamangidwa kuti ithandizire kuyika ma kondakitala ndi kulumikizana koyenera ku ma terminals, kuyikika koyenera kwa ma kondakitala, kukhala kosavuta kuteteza zida zazikulu ku khoma kapena bokosi, ndi malo okwanira.

6.6 Kapangidwe ka socket-outlet sayenera kuletsa kukwerana kwathunthu ndi pulagi yoyenera chifukwa cha zotuluka kuchokera pamalo okwerera.Pulagi ikalowetsedwa mu socket, zimatsimikiziridwa ndi kuyeza kuti kusiyana pakati pa mating pamwamba pa pulagi ndi zitsulo zokwerera pamwamba sikuyenera kupitirira 1mm.

6.7 Pini yoyika pansi iyenera kukhala ndi mphamvu zokwanira zamakina.

6.8 Socket yoyambira, socket socket ndi socket yopanda ndale iyenera kutsekedwa kuti isatembenuke.

6.9 Zingwe zachitsulo zozungulira pansi siziyenera kukhala ndi ma burrs omwe angawononge kutsekemera kwa oyendetsa magetsi.

6.10 Soketi zomwe zimayikidwa m'mabokosi oyika zidzapangidwira kuti mapeto a conductor athe kukonzedwa pambuyo poti bokosi loyika likhazikitsidwe pamalo abwino koma socket isanakhazikitsidwe mubokosi loyika.

6.11 Kulowera kwa zingwe kuyenera kulola kulowera kwa ma chubu kapena ma sheath kuti apereke chitetezo chokwanira pamakina.

7. Osakalamba komanso osachita chinyezi

7.1 Socket iyenera kukhala ndi kukana kukalamba: chitsanzocho chikawonekera ku uvuni wa kutentha kwa 70 ℃ ± 2 ℃ kwa maola 168, chitsanzocho sichikhala ndi ming'alu ndipo zinthu zake sizidzakhala zomata kapena zoterera.

7.2 Socket iyenera kukhala yotsimikizira chinyezi: chitsanzocho chikasungidwa kwa maola 48 pa chinyezi chachibale cha 91% ~ 95% ndi kutentha kwa 40 ℃ ± 2 ℃, kukana kwa insulation ndi mphamvu zamagetsi ziyenera kutsatira malamulo.

8. Insulation resistance ndi mphamvu zamagetsi

8.1 Kukana kwa insulation pakati pa mitengo yonse yolumikizidwa palimodzi ndi thupi ndi ≥5MΩ.

8.2 Kukana kwa insulation pakati pa mitengo yonse ndi ≥2MΩ.

8.3 Ikani kuyesa kupirira voteji ya 50Hz, 2KV ~ pakati pa zigawo zonse kwa mphindi imodzi.Pasakhale kutsetsereka kapena kusweka.

9. Kutentha kumakwera

Pambuyo pa chitsanzo chadutsa mayeso a moyo, kutentha kwa ma terminals ake kuyenera kusapitirira 45K, kutentha kwakukulu kwa zigawo zopezeka zitsulo kuyenera kusapitirira 30K, ndi kutentha kwa magawo omwe si azitsulo omwe amafika sayenera kupitirira 40K.

10. Kuphwanya mphamvu

Pazida zamagetsi zomwe zili ndi voteji yosapitilira 250 V ndi mphamvu yapano yosapitirira 16 A, kugunda kwa zida zoyeserera kuyenera kukhala pakati pa 50 mm ndi 60 mm.

Lowetsani pulagi mkati ndi kunja kwa socket nthawi 50 (mikwingwirima 100), kuchuluka kwa pulagi ndi kutulutsa ndi:

- Pazida zamagetsi zomwe zili ndi mphamvu yapano yosaposa 16 A ndi voliyumu yosapitilira 250V, mikwingwirima 30 pamphindi;

-Pazinthu zina zamagetsi, zikwapu 15 pamphindi.

Pakuyesa, palibe kung'anima kwa arc komwe kumayenera kuchitika.Pambuyo poyesa, chitsanzocho chidzakhala chopanda kuwonongeka komwe kungakhudze kugwiritsidwa ntchito kwina, ndipo dzenje loyikapo pini lidzakhala lopanda kuwonongeka komwe kungakhudze chitetezo chake mkati mwa tanthauzo la chikalatachi.

11.Opaleshoni Yachizolowezi (kuyesa moyo)

Zida zamagetsi ziyenera kupirira kupsinjika kwamakina, magetsi ndi kutentha komwe kumachitika chifukwa chogwiritsa ntchito bwino popanda kuvala mosayenera kapena zovuta zina.M'dera lokhala ndi magetsi ovotera, ovotera pano, COSφ=0.8±0.05, pulagi ndi kutulutsa nthawi 5000.

Pakuyesa, palibe kung'anima kwa arc komwe kumayenera kuchitika.Pambuyo pa kuyesedwa, chitsanzocho sichiyenera kusonyeza: kuvala komwe kungakhudze ntchito yamtsogolo;kuwonongeka kwa nyumba, gaskets insulating kapena zotchinga, etc.;kuwonongeka kwa socket yomwe ingakhudze ntchito ya pulagi;kugwirizana kwamagetsi kapena makina otayirira;kutuluka kwa sealant.kutayikira.

12. Mphamvu yokoka

Soketiyo iyenera kuwonetsetsa kuti pulagi ndiyosavuta kuyika ndikuchotsa ndikuletsa pulagi kuti isatuluke pasoketi ikagwiritsidwa ntchito bwino.

13. Mphamvu zamakina

Zida zamagetsi, mabokosi oyika pamwamba, ma glands opangidwa ndi ulusi ndi zophimba ziyenera kukhala ndi mphamvu zokwanira zamakina kuti zipirire kupsinjika kwamakina komwe kumapangidwa pakuyika ndikugwiritsa ntchito.

14.1 Chitsanzocho chimatenthedwa ndi kutentha kwa 100 ° C ± 2 ° C kwa ola limodzi.Pakuyesa, chitsanzocho sichiyenera kusinthidwa zomwe zingakhudze kugwiritsidwa ntchito kwamtsogolo, ndipo ngati pali zosindikizira, siziyenera kuyenda kuti ziwonetse zigawo zamoyo.Pambuyo pa mayeso, chizindikirocho chiyenera kukhala chomveka.

14.2 Pambuyo poyesa kuthamanga kwa mpira, kuchuluka kwa indentation sikudutsa 2mm.

15. Zopangira, zonyamula pakali pano ndi zolumikizira zake

15.1 Kulumikizana kwamagetsi ndi kumakina kuyenera kupirira zovuta zamakina zomwe zimachitika pakagwiritsidwe ntchito bwino.

15.2 Pa zomangira zomwe zimagwiritsa ntchito ulusi wa insulating ndi zomangira zomwe zimafunika kumangidwa polumikiza zida zamagetsi pakuyika, onetsetsani kuti zawongoleredwa bwino pamabowo kapena mtedza.

15.3 Kulumikizana kwamagetsi kuyenera kukhala kotero kuti kukakamiza kwa kukhudzana sikumaperekedwa kudzera mu insulating material.

15.4 Screws ndi ma rivets ayenera kutsekedwa popanga kulumikiza magetsi ndi makina olumikizira kuti asamasulidwe ndi kuzungulira.

15.5 Zitsulo zonyamulira zamakono ziyenera kupangidwa ndi zitsulo zomwe zimakwaniritsa zofunikira zamakina mphamvu, mphamvu zamagetsi ndi zowonongeka.

15.6 Ma Contacts omwe amatha kutsetsereka pakagwiritsidwe ntchito bwino ayenera kupangidwa ndi chitsulo chosagwira dzimbiri.

15.7 Zomangira zokha komanso zodzicheka siziyenera kugwiritsidwa ntchito kulumikiza zida zonyamula pakali pano.Atha kugwiritsidwa ntchito polumikizira nthaka, pokhapokha ngati zomangira ziwiri zikugwiritsidwa ntchito.

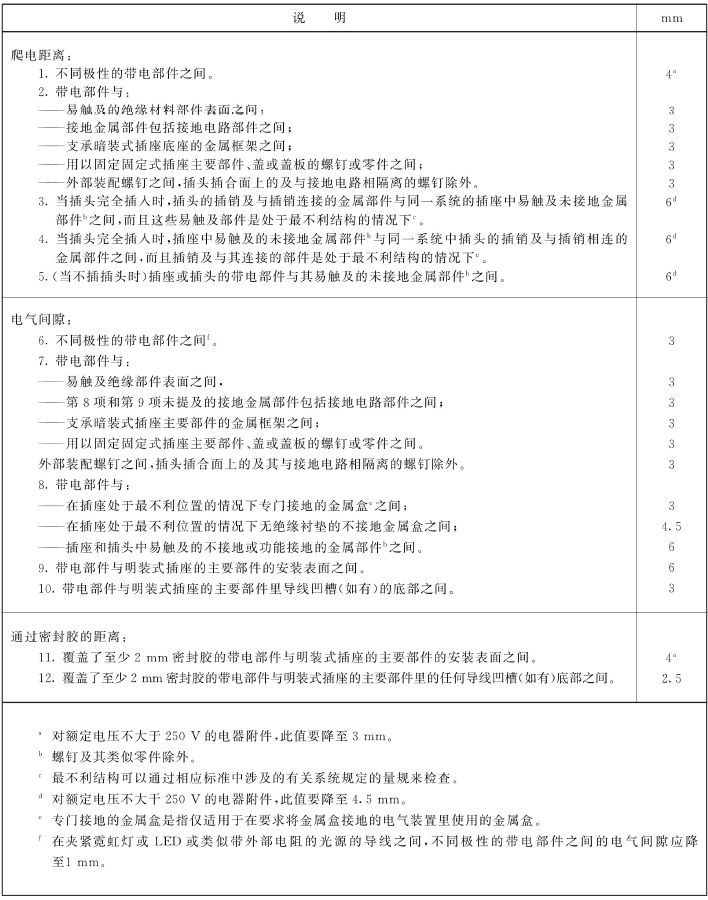

16. Mtunda wa Creepage, chilolezo chamagetsi, kudzera mtunda wotseka wotsekera

Mtunda wa Creepage, chilolezo chamagetsi ndi mtunda wodutsa pa sealant ndi motere:

17.Kutentha kosazolowereka ndi kukana moto kwa zipangizo zotetezera

17.1 Kuyesa kwa waya wonyezimira (kuyesedwa molingana ndi ndime 4 mpaka 10 ya BS6458-2.1:1984) Zipangizo zotchingira zida zonyamula pakali pano komanso magawo ozungulira 850 ℃

17.2 Zida zotetezera za zida zosakhazikika zomwe sizimanyamula komanso magawo ozungulira 650 ℃.

17.3 Pambuyo pa mayesero, palibe lawi lowoneka komanso kuwala kosalekeza, kapena lawi lamoto lizimitsidwa kapena kuwala kumatayika mkati mwa masekondi a 30 mutatha waya wowala;pepala la minofu siligwira moto, ndipo bolodi la paini siliwotcha.

18

Zigawo zachitsulo sizidzawonetsa dzimbiri pambuyo poyesa dzimbiri.

Nthawi yotumiza: Feb-05-2024