1. Scope

The technical requirements and test items for the use conditions, electrical performance, mechanical properties and environmental performance of lithium primary batteries (clock batteries, power outage meter reading), etc., integrate the acceptance test standards for lithium primary batteries.

Acceptance, regular confirmation, and full performance inspection of lithium primary batteries

High and low temperature alternating humidity and heat test chamber

Salt spray test chamber

Vernier caliper

Battery function tester

Vibration test device

Impact test device

multimeter

3.1 Packaging requirements

Packaging design should conform to the nature, characteristics and storage and transportation conditions of the product. The packaging box should be marked with the manufacturer's name, product name, product model, date of manufacture and packaging quantity. The outside of the packaging box should be printed or affixed with transportation signs such as "Handle with Care", "Afraid of Wet", "Up" and so on. The logos printed or affixed on the outside of the packaging box must not fade or fall off due to transportation conditions and natural conditions. The packaging box should meet the requirements of moisture-proof, dust-proof and shock-proof. The inside of the package should have packing list, product certificate, accessories and other relevant random documents.

3.2 Basic requirements

3.2.1 Temperature range

The ambient temperature should comply with the table below.

| No. |

Battery Type |

temperature(℃) |

| 1 |

clock battery(Li-SOCl2) |

-55~85 |

| 2 |

Power outage meter reading battery(Li-MnO2) |

-20~60 |

3.2.2 Humidity range

The relative humidity of the air should comply with the table below.

|

No. |

Condition |

Relative humidity |

|

1 |

Average per year |

<75% |

|

2 |

30 days (these days are naturally distributed throughout the year) |

95% |

|

3 |

Appear by chance on other days |

85% |

3.2.3 Atmospheric pressure

63.0kPa~106.0kPa (elevation 4000m and below), except for special order requirements. High-altitude areas require normal operation at an altitude of 4000m to 4700m.

Lithium primary batteries should at least be marked with the manufacturer's name, trade name or trademark, production date, model, nominal voltage, nominal capacity, and safety certification mark. Batteries should be marked with "Warning" and have the following or equivalent expression: "Battery has the risk of fire, explosion and combustion. Do not recharge, disassemble, squeeze, heat above 100°C or incinerate. Keep it in the original packaging before use. "The marked content should be consistent with the detailed technical specifications.

The detailed technical specifications of lithium primary batteries include at least nominal voltage, open circuit voltage, operating temperature, nominal capacity, nominal energy, pulse performance, maximum continuous discharge current, average annual self-discharge rate, size, connector form, trademark, and manufacturing Corporate identification logo and other content.

(1) Open circuit voltage

(2) Load voltage

(3) Pulse performance

(4) Passivation performance

(5) Nominal capacity (applicable to full performance test)

3.5 Mechanical performance requirements

The battery should undergo the terminal strength test, impact test, and vibration test specified in 5.6 of this test standard. After the test, the battery will not leak, discharge, short-circuit, rupture, explode, or catch fire, and the welding piece will have no breakage or visible damage. The quality The change rate is less than 0.1%.

3.6 Soldering performance

3.6.1 Solderability (applicable to types with metal solder tabs)

When the battery is tested in 5.7.1 of this test standard, the wetting force should not be less than 90% of the theoretical wetting force.

3.6.2 Resistance to welding heat (applicable to types with metal welding tabs)

The battery is subjected to the test 5.7.2 of this test standard. After the test, the appearance of the lithium primary battery does not have any mechanical damage. The electrical test should comply with the relevant requirements of the technical specifications.

3.7 Environmental performance requirements (applicable to full performance test)

Lithium primary batteries undergo the environmental test 5.8 of this test standard. The electrical test carried out after the test shall comply with the relevant technical requirements of its detailed technical specifications.

3.8 Safety test (applicable to full performance test)

Lithium primary batteries should meet the following technical requirements when conducting safety tests in 5.9 of this test standard.

| No. | Pilot projects | Requirement |

| 1 | high altitude simulation | No leakage, no discharge, no short circuit, no rupture,no explosion, no fire,The mass change rate should be less than 0.1%. |

| 2 | free fall | |

| 3 | external short circuit | It doesn't heat up, burst, explode, or catch fire. |

| 4 | Heavy object impact | No explosion, no fire. |

| 5 | extrusion | |

| 6 | Abnormal charging | |

| 7 | Forced discharge | |

| 8 | hot abuse |

4. Test methods

4.1 General requirements

4.1.1 Test conditions

Unless otherwise specified, all tests and measurements shall be performed under the following environmental conditions:

Temperature: 15℃~35℃;

Relative humidity: 25% ~ 75%;

Air pressure: 86kPa~106kPa.

4.2 Check relevant technical documents

(1) Confirm whether the specification quantity and name are consistent with the delivery inspection form;

(2) Check whether the manufacturer is a qualified supplier.

4.3 Packaging inspection

(1) Check whether the packaging box is marked with the following information in a conspicuous position: manufacturer name, product name, product model, inspection date and packaging quantity, and whether the marked content has faded or fallen off.

(2) Check whether the packaging box is printed or affixed with transportation signs such as "Handle with Care", "Afraid of Wet", "Upward", etc. in a conspicuous position, and whether the contents of the signs are faded or peeled off.

(3) Check whether the inner and outer packaging of the products in the box are deformed, damaged, damp or squeezed.

(4) Check whether the documents in the packaging box are complete. At least there should be packing list, product certificate, accessories and other relevant random documents.

4.4 Appearance inspection and dimensional inspection

Visual inspection method is used to check product status, processing quality and surface quality, and measure dimensions to meet the requirements of 4.3. Including but not limited to the following:

(1) Whether the markings (text symbols or graphic marks) comply with the requirements of the specification;

(2) The label must not have any unreadable defects (blurred, overflowing, incomplete, disconnected);

(3) It should be clean, free of pollution, no defects, and no mechanical damage;

(4) The dimensions should meet the detailed technical specifications and tolerance requirements.

4.5 Electrical test

(1) Open circuit voltage test

(2) Load voltage test

(3) Pulse performance test

(4) Passivation performance test (applicable to Li-SOCl2 batteries)

(5) Nominal capacity test

4.6 Mechanical performance test

(1) Terminal strength test (applicable to types with metal solder tabs)

(2) Impact test

(3) Vibration test

4.7 Soldering performance test

(1) Solderability test (applicable to types with metal solder tabs)

(2) Welding heat resistance test (applicable to types with metal welding tabs)

4.8 Environmental testing

(1) Thermal shock test

(2) High temperature and high humidity test

(3) Salt spray test

4.9 Safety test

In view of the strong professionalism of safety testing, suppliers are required to provide third-party test reports.

(1) High simulation test

(2) External short circuit test

(3) Heavy object impact test

(4) Extrusion test

(5) Forced discharge test

(6) Abnormal charging test

(7) Free drop test

(8) Thermal abuse test

5.Inspection rules

5.1 Factory inspection

The manufacturing unit shall conduct factory inspection on each product produced according to the test methods provided in this test standard. After passing the inspection, a quality certificate will be issued. For inspection items, refer to the appendix.

5.2 Sampling inspection

Sampling inspection shall be carried out in accordance with the sampling method specified in GB/T2828.1 "Counting Sampling Inspection Procedure Part 1 Batch-by-batch Inspection Sampling Plan Retrieved by Acceptance Quality Limit (AQL)". According to this test standard, test items are divided into two categories: A and B. Category A is a veto item, and category B is a non-veto item. If any Category A failure occurs in the sample, the batch will be judged to be unqualified. If a Category B failure occurs and the test passes after rectification, the batch will be judged to be qualified.

5.3 Periodic confirmation testing

Regular confirmation sampling shall be carried out in accordance with the "Periodic Confirmation and Inspection System for Key Materials", and testing shall be carried out in accordance with the test items, test requirements and test methods specified in this test standard to determine the compliance of the product characteristics with the provisions of this test standard.

During the periodic confirmation test, if any one or any item of the sample fails, the product will be judged to be unqualified, and the manufacturing unit will be notified for quality confirmation and rectification.

5.4 Full performance test

Test according to the test items, test requirements and test methods stipulated in this test standard to determine the compliance of the product characteristics with the provisions of this test standard.

The full performance test is suitable for sample inspection by the manufacturing unit. In the full performance test, if any one or any item of the sample fails, the product will be judged to be unqualified.

6 storage

Well-packaged products should be stored in a warehouse with a temperature of 0°C to 40°C, a relative humidity of RH <70%, an atmospheric pressure of 86kPa to 106kPa, ventilation and no corrosive gases.

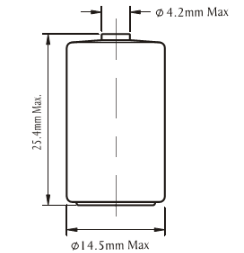

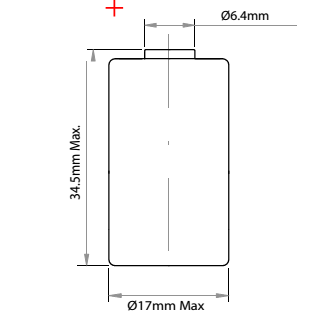

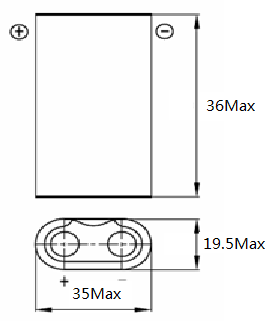

Appendix A: Reference dimensions

A.1 Clock battery (14250)

A.2 Power outage meter reading battery (CR123A)

A.3 Power outage meter reading battery (CR-P2)

Post time: Nov-29-2023