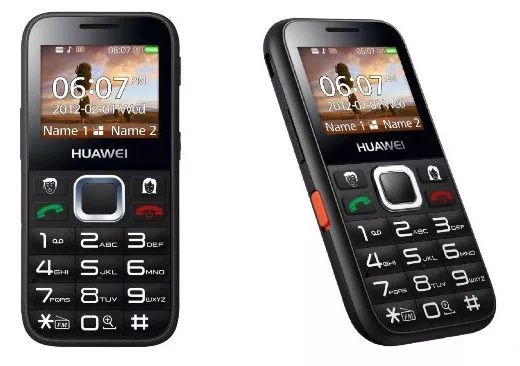

Mobile phones are definitely the most frequently used products in daily life. With the development of various convenient apps, our daily necessities of life seem to be inseparable from them. So how should a frequently used product like a mobile phone be inspected? How to inspect GSM mobile phones, 3G mobile phones and smart phones? As a product with many functions, what inspection items need to be completed?

1. Specific inspection methods (full inspection)

Preparation before inspection

Determine the signal sources required for this test (such as various WIFI signals, etc.)

Determine the files or software required for testing (various image formats, audio formats, file formats, anti-virus software)

Determine the external devices required for testing (such as car cigarette lighter plug, headphones, SIM card, U disk, memory card, etc.)

Determine the voltage and frequency used

Determine the socket used

Determine whether the equipment is calibrated and whether the expiration date is valid

Determine the number of sets of test equipment that can be provided

Determine the testing environment and equipment for Running test

Ask the factory to provide specifications for the display screen and camera.

1) The test voltage should be the rated voltage and frequency

(1) Safety test

(2)Shock test

(3) Check the default software and hardware version, default country, and default language

(4) Each button and interface on the test equipment

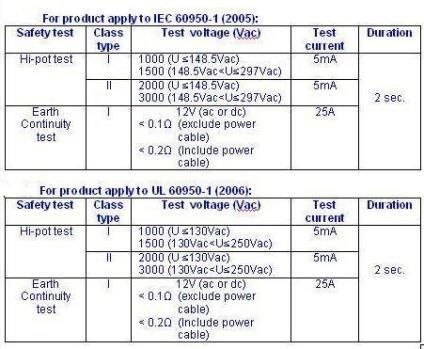

1) Safety test standards can be referred to

(1) IEC: International Standard (201106 Edition)

(2) UL: American Standard (201106 Edition)

2) Check whether the IMEI numbers on the outer box, color box, and machine label are consistent..

3) Check whether the sealing strips of the outer box and color box are firm and not damaged.

4) First install the SIM card, SD card, battery and battery cover yourself. The battery and cover must be easy to install and remove without using assistance tools. Pay attention to whether the contact surfaces of the SIM card and SD card are rusty or moldy.

5) Check immediately when turning on the computer:

(1) Boot logo

(2)Default country

(3)Default language

(4)Default time

(5)Software version

(6)Hardware version

(7) Contents on the built-in memory (no redundant or missing test files)

6) Connect the charger (AC power adapter and car adapter) for charging check.

7) Connect the wired headset or Bluetooth headset and prepare for the next test

8) Enter *#06# and check whether the IMEI number displayed on the LCD screen is the same as the IMEI number on the color box and the body.

9) Check the button backlight and light transmittance

(1) The buttons on the mobile phone are all backlit, making it easier to operate at night. When checking, pay attention to whether the backlight is uniform and the brightness is sufficient. When checking the key backlight, if the surrounding environment is bright, you can cover the keyboard with your hands to see.

10) Test each button on the machine to see if it has any function, whether the key is jammed (jammed key), and whether there is any abnormal sound. Pay special attention to the navigation key.

When entering the test mode, during the keyboard test step, press the corresponding key, and the corresponding key on the screen will change color.

11) Conduct an actual call test, pay attention to the ring tone type and vibration function, and confirm that the call quality is normal when the volume is set to the maximum.

a) When using the built-in speaker

b) In case of hands-free function test

c) Test the function of wired headsets and Bluetooth headsets to answer calls

(Priority is given to using the short number group for testing. If there is no short number card in the factory, you can dial 10086 or 112 special numbers for testing, but do not miss the microphone test)

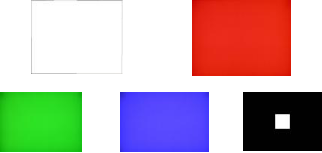

12) Check each monochrome screen of the mobile phone display (white, red, green, blue, black)

13) There are two methods for batch inspection of display screen quality

(1) Check through the built-in test software of the machine

(2) Pass the three primary color monochrome screen inspection

a. Observe each monochrome picture (white, red, green, blue, black)

b. Main observations under monochrome display:

(a) Watch the highlights on a black screen

(b) See dark spots on a white screen

(c) Confirm whether it is a bright spot or a dark spot on other screens

(d) Color purity and uniformity can be checked

(e) Check light leaks and spots Mura under black screen

14) Check the reception sensitivity of the mobile phone (see whether the same phone can receive the same number of signal bars at the same location)

15) Conduct touch screen reaction test

(1) Generally, during testing, you can touch points around the screen and on the screen to see if it responds.

As shown in the product test shown below, after entering the test mode, after touching each small red square, it will turn blue-green.

(2) Multi-touch technology (Multi-Touch)

That is, multiple points can be controlled simultaneously on one touch screen. That is, the screen will be able to recognize clicks and touches made by your five fingers at the same time. For example, you can easily zoom in and out of images with just two fingers.

(1) Move the lens to observe the surrounding scenery, observe whether the image in the viewfinder is normal, shoot an object (such as a face) at a distance of 3 meters, and see whether it can automatically focus and whether the photo is normal (no discoloration, blur, lines, or black shadows) etc. defective)

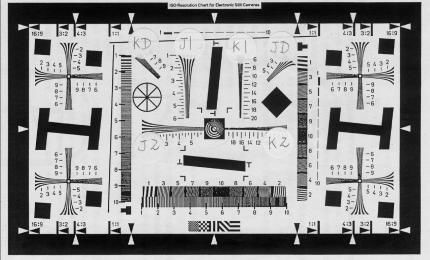

(2) Some factories will use some test cards to test resolution and color:Such as ISO12233 card, Jiugong color card.

- ISO 12233 resolution test card

b. For Jiugong color pictures, just look at the color reproduction of the camera, and there are no discoloration, odd spots, ripples and other undesirable phenomena.

(3) Camera flash function:

Turn on the camera’s flash function and see if the photos taken under the flash are normal.

Main checks: whether they are synchronized; whether there is excessive whitening.

17) Video recording function test

Record people walking around and see if the video and audio played after recording are smooth.

18) Recording and playback function test

19) Randomly play video and audio of a certain format. Check the playback quality of images and audio when the volume is set to maximum.

20) Randomly browse pictures, texts, and e-books in a certain format

21) SMS sending and receiving test

22) Check whether the various built-in sensors are working properly

(1) Ambient Light Sensor

When checking, cover the left hole with your hand and the LCD screen will darken.

(2) Proximity Sensor—distance sensor

During the inspection, you can put your hand close to the earpiece of the mobile phone and watch whether the LCD screen will automatically turn off. After you move it away, the LCD screen will light up again.

(3) Orientation Sensor

When checking, after the phone is rotated, the screen image can automatically rotate and switch the aspect ratio, and the text or menu can also be rotated at the same time, making it easier for you to read.

(4) Accelerometer, G-sensor

What the gravity sensor can measure is a straight line. It is a force sensor.

(5) Electronic compass, also called azimuth sensor (E-compass)

You can install a compass software during inspection, and the pointer on it will change with the direction of rotation.

Generally, electronic compasses (E-compass) and acceleration sensors (G-sensor) are now often combined inside a chip, and these two sensors must also be used together.

(6)Temperature transducer

Generally, you can see the temperature of the battery in the factory test mode, which indicates that a temperature sensor has been built in.

(7) Gyroscope

When the user rotates the phone, the gyroscope can sense the offset in the three directions of X, Y, and Z and convert it into digital signals, thereby accurately controlling mobile games.

18) Conduct 3G – Video Call video call test: when the signal is good, the video and audio should not be delayed.

24) Network cable connection test

(1) GPRS Internet function check

(2) Wi-Fi wireless network connection test, open the www.sgs.com website and accept it

(3) Bluetooth network connection test requires discovering and connecting the attached Bluetooth device.

25) Functional testing of USB interface, HDMI port, TF card, and each connecting cable (note: all input and output interfaces on the device need to be fully inspected)

26) If the mobile phone has a USB port connected to the computer, manual virus checks need to be performed on all mobile phones (please use the latest version of anti-virus software and virus database)

27) Confirmation of the equipment’s own capacity

28) Carry out FM/TV receiving function test. (If the TV function cannot be viewed at the inspection location or the image is unclear when viewing, you need to download remark)

29) Carry out GPS satellite search test (it is recommended to conduct it outdoors, and 4 satellites need to be received within the specified time)

30) Shutdown screen check

31) For inspection of accessories (such as stylus, case, strap, etc.), it is recommended that the accessories of each machine be inspected together with the main unit, and separate inspection is not recommended.

remind:

1. During the inspection, you can use the factory’s self-test software to check the above items, but make sure that each item can be tested. Contents that are not tested by the self-test software must be tested separately.

2. After the test is completed, be sure to notify factory personnel to delete the test records in the device and restore the factory settings.

3. Mobile phone appearance requirements are strict, so pay special attention during inspection

1) The surface of structural parts must not be scratched, dirty or poorly painted.

2) The front and rear shells of the mobile phone and the touch screen are evenly spaced (< 0.15mm) and the steps are even (< 0.1mm).

3) Are there any missing, loose or twisted screws on the back cover?

The instruction manual, color box, and spec have relevant indicator tests mentioned.

Make a call to a colleague and check the actual call effect with each other, paying attention to whether there is noise, bass, abnormal sidetone and echo.

Test the working current and standby current of the built-in battery

Built-in storage disk capacity

When testing black-and-white screen and color-screen LCD, take multiple samples and turn them on together to compare to see if there is any color deviation between the machines.

Touch screen calibration test

The camera and flash shoot with autofocus at 1 meter, 2 meters and 3 meters

Note: If the indicators mentioned in the manual, color box, and SPEC cannot be confirmed or tested on site, you need to put a Remark or information explanation in the report.

Since some indicators in the spec (such as transmit power, sensitivity, frequency offset, etc.) require professional instruments and professional personnel to test, in normal inspection, except for special requirements from customers, inspectors generally do not need to check (indicators that have not been tested cannot be Written as confirmed or tested)

Reminder:

(1) When testing the battery, it is recommended to charge the device as soon as it arrives at the factory. In this way, the battery can be charged for about 4 hours. Start playing audio and video in the afternoon to see how many hours of continuous playback it can.

(2) Pay special attention to whether the battery capacity meets the specification and whether the actual discharge time is too short.

(3) Pay attention to whether the part of the product near the battery is abnormally hot to the touch. If it is found to be hot, remark it.

5. Confirmation test (Quantity: one)

1) Check the content and functions of the manual (check every word and sentence)

2) Whether the factory settings of the machine are correct.

3) Installation and use of the mobile phone’s own software

4) Color box, SPEC or BOM content verification

5) Confirmation of plugs and power cords in relevant countries

6) Commonly used approval marks on batteries

7) Confirm the manufacturer and model of the display screen

8) Screen size measurement and screen resolution confirmation

9) Maximum recognized SD card capacity

10) Test whether you can browse normally and play files, audio and video in various formats mentioned in the manual.

11) Can you call emergency numbers 911, 119, 110, etc. in the relevant country without a card or locked keyboard?

12) After changing the menu content, re-enter the Default setting test (check whether the changed language, brightness, etc. settings can be restored to the Default setting)

13) Confirm the required Approval mark for the country and product used

14) In WiFi, test whether the connection can be made correctly under different encryption methods.

15) The sliding cover and flip-cover machines perform 100 rapid opening and closing tests every two seconds.

16) Functional test of network lock and card lock

17) Low battery alarm function

18) Australia and New Zealand communications product compulsory certification mark A-tick

19) Carton Drop Test (1 corner, 3 sides and 6 sides) (Before dropping, you need to confirm with the factory whether this test is allowed)

After the drop test, attention should be paid to the internal inspection: Are the pillars connected to the rotating part cracked?

6. Internal check Internal check (number of samples: one)

1) LCD mark

2)Battery mark

3) CPU mark

4) Flash IC mark

5)Wi-Fi module mark

6) PCB marking

7) Workmanship inspection

Compare the sample (if any) to check the internal structure of the product and its process. The product structure should be consistent with the sample. Plastic parts should not be damaged, melted, deformed, etc. Metal parts should not be rusted, damaged, etc.

- 1. Holder’s workflow

1) Arrange the Assistant’s work first, such as how to partition the inspected products to be inspected, scan the IMEI barcode of the product, check whether the barcodes of the color box and outer carton are consistent, etc.

2) Tell the Assistant the key points of appearance inspection and the usual functional inspection methods (for example, for mobile phone products, you usually check the IMEI number, check the version number, call 112 or 10086 for call test, enter the engineering test mode for various tests, reset test, etc.) , let the Assistant first become familiar with the product and inspection procedures.

3) After confirming that the Assistant is familiar with the product and starting the batch inspection of the product, Holder first reviews the inspection methods for equipment functions in SPEC and lists the main contents to be inspected (such as charging inspection, IMEI inspection, confirmation of each software and hardware version number, dialing Call inspection, inspection in engineering mode, etc.) is written on a piece of paper to remind and notify the Assistant to perform a complete inspection according to the prompts.

4) Holder reviews and checks the complete SPEC and all information, and lists the problematic areas

5) Holder checks the product instructions in the color box and lists the problematic areas

6) Holder starts taking pictures (if the product is a mobile phone, the phone’s on and off logo, standby screen, menu interface, and interface pictures of each version number must be taken)

7) Holder starts writing the inspection report.

8) Holder uses verification to check the light and dark codes of all barcodes.

9) Holder starts inspecting the products to be inspected.

10) 15 minutes before the inspection is about to be completed, Holder stops the inspection work and notifies factory or customer personnel to go to the site to check for defective products.

11) After checking the defective products, complete and print the report

1) Scan or record the IMEI number or serial number of the product

2) Ask the holder about the appearance inspection and functional inspection content, and start inspecting the product

3) When inspecting the mobile phone, you can inspect it in the following order to improve the inspection speed. The specific method is: product → open the back cover → check the metal contact surface of each card holder, model label, seal warranty label, each screw, and the appearance of each place inside the cover → Install the SIM card, TF card, and battery → close the cover and turn on the phone → check the appearance during boot → function check

(This step is mainly because it takes a lot of time to turn on the device and search the mobile network. The inspector can use the time of turning on the device and logging into the mobile network to check the appearance).

4) The defective products found must be labeled with defects, and the detailed defective content shall be written down, and then discharged in separate areas. Unchecked defective products must be protected, and the factory is not allowed to inspect defective products without permission.

5) After inspecting the products, the inspector should put them back in the same color box, and pay attention to the placement method to avoid causing damage to the product parts.

1) If the products to be inspected are not unlocked, those products that have been unlocked must be labeled and placed in partitions

2) Inspected and un inspected products should be placed in separate areas;

3) Products in different boxes should be placed separately. Before placing them, coordinate with the factory to see how to control them on site to avoid mixing up the products.

4) The factory can only help with unpacking, and is not allowed to help insert cards (SIM cards/SD cards/TF cards, etc.) and install batteries.

Introduction to some defective products

1) Setting error

2) Defective screen

3) There is a problem with the buttons

4) The wireless network keeps dropping offline

5) The built-in sensor is not sensitive

6) During the editing and conversion of styles, the conversion of symbols in each style is abnormal.

7) When operating various functions during a call, abnormal phenomena such as crashes, call interruptions, and slow response may occur.

8) The product is overheated

9) Abnormal call

10) Short battery life

11) Missing inspection of accessories

12) The application, copying, and deletion between the local memory and the Micro SD card may cause abnormal phenomena such as crashes and slow response.

13) Large keyboard gap

14) Poor installation

15) Poor shooting

16) Poor screw installation

17) Missing key

Post time: Oct-30-2023