Children's toys are good helpers for accompanying children's growth. There are many types of toys, including plush toys, electronic toys, inflatable toys, plastic toys, and so on. Due to the increasing number of countries implementing relevant laws and regulations to care for the healthy growth of children, special attention needs to be paid during toy inspection. Here are the inspection items and methods for inflatable toys. If you find them useful, you can bookmark them!

1.On site verification of BOOKING

After arriving at the factory, it is necessary to clarify the inspection tasks for the day with the factory manager, and promptly report any issues to the company to see if there are any of the following issues:

1) The actual production quantity of goods did not meet the inspection requirements

2) The actual production quantity of goods has changed compared to the order

3) The actual inspection location does not match the application

4) Sometimes factories may mislead INSPECTOR in expressing the quantity of sets

2.Box extraction

Number of boxes drawn: Generally, FRI follows the square root of the total number of boxes, while RE-FRI is the square root of the total number of boxes X 2

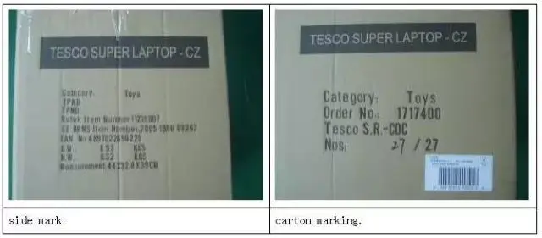

3.Verify the marking of the outer and inner boxes

The marking of the outer and inner boxes is an important symbol for product shipment and distribution, and symbols such as fragile labels can also remind consumers of process protection before the product arrives. Any discrepancies in the marking of the outer and inner boxes should be pointed out in the report.

4. Verify whether the ratio of outer and inner boxes and product packaging meet customer requirements, and provide a detailed description of the packaging items in the report.

5. Verify whether the product, sample, and customer information are consistent, and any differences should be taken seriously.

Please note:

1) The actual function of inflatable toys, whether the accessories are consistent with the packaging color picture, instructions, and so on

2) Marking for CE, WEE, age classification, etc

3) Barcode readability and correctness

1.Appearance and on-site testing

A)Appearance inspection of inflatable toys

a. Retail packaging for inflatable toys:

(1) There should be no dirt, damage, or moisture

(2) Cannot omit barcode, CE, manual, importer address, place of origin

(3) Is there an error in the packaging method

(4) When the circumference of the packaging plastic bag opening is ≥ 380mm, a hole needs to be punched and a warning message should be provided

(5) Is the adhesion of the color box firm

(6) Is the vacuum molding firm, is there any damage, wrinkles, or indentations

b. Inflatable toys:

(1) No sharp edges, sharp points

(2) Children under three years old are not allowed to produce small parts

(3) Is the instruction manual missing or poorly printed

(4) Missing corresponding warning labels on the product

(5) Missing general decorative stickers on the product

(6) The product must not contain insects or mold marks

(7) The product produces an unpleasant odor

(8) Missing or incorrect components

(9) Rubber parts deformed, dirty, damaged, scratched, or bumped

(10) Poor fuel injection, leakage, and incorrect spraying of components

(11) Poor color injection molding, bubbles, spots, and streaks

(12) Parts with sharp edges and uncleaned water injection ports

(13) Defective function

(14) The valve plug can be inserted into the inlet seat when filled with gas, and the protrusion height must be less than 5mm

(15) Must have a reflux valve

B)On site testing of general inflatable toys

a. Complete assembly testing must be consistent with the instructions and packaging color box description

b. Complete inflation function test for 4 hours, must be consistent with the instructions and packaging color box description

c. Product size check

d. Product weight check: facilitates verification of material consistency

e. Printing/marking/silk screen for 3M tape testing products

f. ISTA drop box test: One point, three sides, six sides

g. Product tensile testing

h. Functional testing of check valves

Post time: May-07-2024