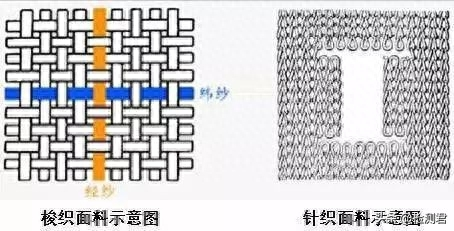

Knitting is a weaving process for fabrics commonly used in clothing. At present, most of the fabrics in our country are knitted and woven. Knitted fabrics are formed by forming loops of yarn or filaments with knitting needles, and then interlocking the loops. A woven fabric is a fabric formed by interweaving warp and weft yarns perpendicular to each other.

According to different process characteristics, knitting is divided into two categories: weft knitting and warp knitting. Knitted fabrics are fluffy, soft, smooth, less hairy, have good wrinkle resistance and air permeability, and have greater extensibility and elasticity. They are comfortable to wear and are mostly used to make close-fitting clothing. When it comes to inspection, the inspection points for knitted garments are also slightly different:

Key Points for Inspection of Knitwear

Compare the product with the customer's confirmation sample, reference sample, craft sheet, color sample or picture, etc., to judge whether the style and sewing process are correct.

Style and color comparison

Focus: Appearance attention to detail

Check whether the overall appearance of the product is consistent with the customer's requirements; whether the weft of the fabric exceeds 5%; knitwear is not allowed to be sewn with a flat car or three-thread overlay; check the cleanliness of the appearance, whether there is dirt or oil on the product surface; whether the left and right are symmetrical , Whether the stripes are aligned; whether the shape of the collar and placket is skewed; whether the zipper is seriously arched; whether the hem is smooth, whether the pockets are high or low, etc.;

Production Process Inspection

Emphasis: Craftsmanship Craftsmanship for the exterior and interior of garments

Whether the patchwork is straight; whether the stitches are even, whether there are broken threads, jumpers, pits, bursts, pleats, etc.; whether the embroidery, embossing, printing, etc. are clear; the positioning of pockets, bag flaps, sleeve loops, buttons, etc. Whether it is accurate; whether the fabric lining has weaving defects, irreparable needle holes, etc.; whether the size and length of the lining of each part are suitable for the fabric; whether the left and right sleeves and trouser legs are the same length;

Focus: Multi-dimensional chromatic aberration contrast

Inspect bulk products and samples, whether there is color difference between bulk products and products; inspect whether there is color difference in different parts of the fabric on the same piece of clothing.

Fabric Feel and Product Smell

Focus: feel, smell, feel, visual inspection, smell

The feel of the fabric must meet the requirements and be consistent with the sample; the product has no odor or peculiar smell.

Accessories and Ingredients Inspection

Key points: attachment quality firmness, location, etc.

Check the quality of accessories, style, size, workmanship, color, function, firmness of sticking or attachment, and whether the position meets the requirements.

Trademark and Logo Inspection

Key points: trademark, logo position, content, completeness, etc.

Check whether the trademark, cleaning label, hang tag, etc. are installed in the correct position as required; whether the content of the logo (text and pattern) is consistent with the information; whether the logo is clear, whether it is missing, damaged, or not firmly fixed, etc.

Packaging Inspection

Key points: packaging, packaging, outer boxes, etc.

Check whether the product packaging method meets the requirements; check whether the outer box size, gross weight, carton material, box marking information, and packing ratio are correct; whether the packaging is damaged.

Focus: Functional test dimensions, barcodes, fillings, etc.

In addition to the above detection points, a detailed functional test is required for the following:

Size measurement; barcode scanning test; filling inspection test; color fastness test; box gauge box weight test; unpacking test (packing ratio, quantity, etc.); needle detection test, etc.

The above are some key points of the inspection of knitted garments. In the specific inspection work, it is necessary to do targeted inspection and testing according to the requirements of customers.

Post time: Sep-01-2023