During the wearing process, clothing is constantly exposed to friction and other external factors, causing the formation of hairiness on the surface of the fabric, which is called fluffing. When the fluff exceeds 5 mm, these hairs/fibers will entangle with each other to form irregular balls, which is called pilling.

01Why does it pill?

As the fabric continues to rub during use, the fiber balls gradually become closer, and the fibers connected to the fabric are repeatedly bent, fatigued, and even broken in different directions. The fiber balls fall off the surface of the fabric, but the fiber hairiness at the broken end will remain after that. During use they continue to be pulled out and form fiber balls again.

Generally speaking, wool fibers and chemical fibers are prone to pilling, especially carded wool fabrics or wool-like carded fabrics and cashmere fabrics. From the perspective of yarn and tissue structure, the yarn twist is small, the hairiness is high, the fabric structure is loose, and twill and satin fabrics with long floating lines are prone to pilling.

In addition, from the perspective of processing form, generally the fiber twist is large, the cohesion between fibers is large, and the fabric structure is relatively tight and smooth, so it is not easy to pill. On the contrary, the pilling phenomenon is more serious in blended fabrics, especially nylon, polyester, polypropylene, etc. This is mainly because blended fabrics have different twists between fibers, and the surface of the fabric is prone to lint.

02How to test pilling?

In order to ensure the safety and comfort performance of clothes or textiles during use, the fabrics will be tested for pilling performance before they are made into finished products or after the garments are completed.

The test method standards for pilling of clothing and textile products are:

GB/T 4802.1-2008 "Circular trajectory method"

GB/T 4802.2-2008 "Modified Martindale Law"

GB/T 4802.3-2008 "Pilling Box Method"

GB/T 4802.4-2020 "Random Tumbling Method"

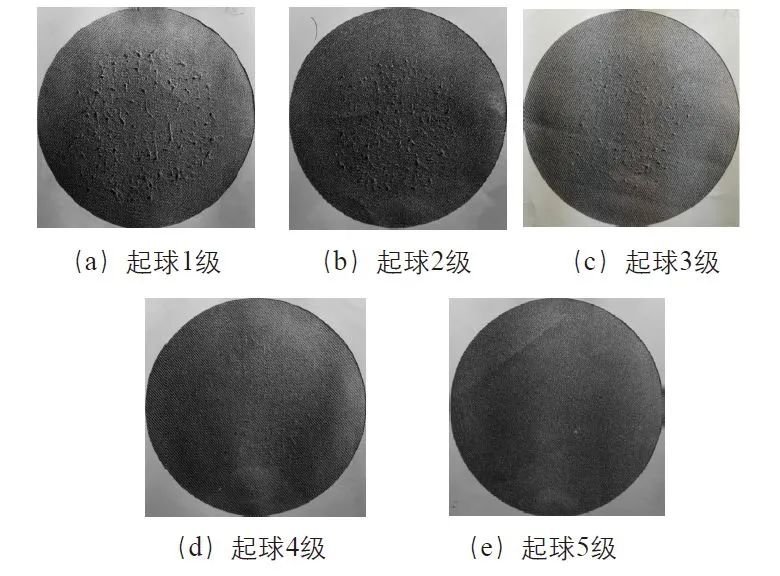

Although they all test the pilling degree of fabrics, the above methods are applicable to different clothing fabrics and the working principles of the instruments are also different. The tested pilling performance is expressed in the form of a grade, which is generally divided into grades 1 to 5. The larger the grade, the less likely the clothes are to pill. The general standard stipulates that the index ≥ level 3 is a qualified product.

2.1 Circular trajectory method

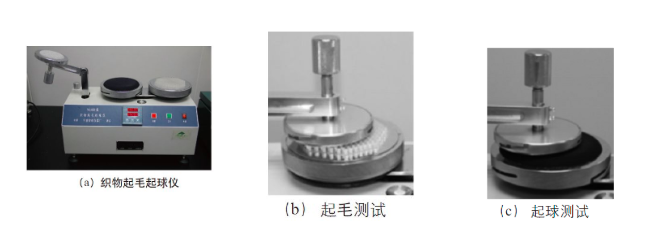

The principle of GB/T 4802.1-2008 "Circular Trajectory Method" is that the sample is rubbed with a nylon brush and fabric abrasive or only with fabric abrasive for a specified number of times under a specified pressure to cause pilling on the surface of the sample.

This method has a fast test speed and can simulate the friction and pilling of the fabric after being hooked. Suitable for clothing woven fabrics and knitted fabrics such as sweatshirts and T-shirts.

Taking GB/T 4802.1-2008 "Circular Trajectory Method" to test the pilling of fabrics as an example, Figure 2 is a photo of a chemical staple fiber fabric sample with pilling levels 1 to 5.

Figure 1 Circular trajectory method pilling instrument and test process

Figure 2 Example of sample pilling grade

2.2 Modified Martindale method

The principle of GB/T 4802.2-2008 "Modified Martindale Method" is that under specified pressure, the circular sample rotates freely around the central axis perpendicular to the plane of the sample, and the trajectory of the Lissajous figure is consistent with the same fabric or Wool fabric abrasives are used for friction, which is suitable for bed type testing.

Figure 3 Martindale pilling tester

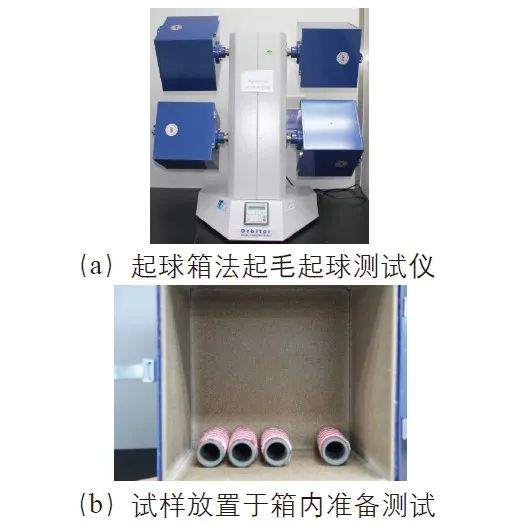

The principle of GB/T 4802.3-2008 "Pilling Box Method" is: the sample is installed on a polyurethane tube and turned over randomly in a wooden box lined with cork with a constant rotation speed. After the specified number of flips, the fuzzing and/or pilling properties are visually described and evaluated. Suitable for testing sweater textiles.

Figure 4 Pilling box method pilling tester and sample placement

The principle of GB/T 4802.4-2020 "Random Tumbling Method" is to use a random tumbling pilling box to cause the fabric to tumble and rub randomly in a cylindrical test chamber paved with cork lining and filled with a small amount of gray short cotton. Domestic clothing product standards have not yet cited this method.

Figure 5 Random tumbling method pilling tester

Testing precautions: When non-garment samples are sent for inspection, the front side when used must be marked to avoid testing side errors. For combing, carding, etc. that have different parameter requirements, attention should be paid to parameter selection.

Post time: Jan-23-2024