Paper, Wikipedia defines it as a non-woven fabric made of plant fibers that can be folded at will for writing.

The history of paper is a history of human civilization. From the emergence of paper in the Western Han Dynasty, to the improvement of papermaking by Cai Lun in the Eastern Han Dynasty, and now, paper is no longer just a carrier for writing, but can also be used for other purposes such as printing, packaging, industry, and life.

In this issue, let's take a look at the general inspection/inspection key points and common defect judgments of paper products.

Scope of application

The products to which this guideline applies include: cultural paper, industrial and agricultural technical paper, packaging paper and household paper. My country's imported paper is mainly cultural paper (newsprint, coated paper, offset paper, writing paper) and packaging paper (kraft cardboard, white cardboard, corrugated base paper, white cardboard, cellophane, etc.).

02 Inspection focus

| Appearance

The appearance of the paper is an important factor in determining the quality of the paper. It not only affects the appearance of the paper, but some appearance defects also affect the use of the paper.

General Inspection Guide for Paper Products

The appearance quality inspection of paper mainly adopts the methods of face-to-face inspection, flat inspection, squint inspection and hand-touch inspection. The surface of the paper is required to be flat and clean, and no folds, wrinkles, damage, hard blocks, light-transmitting spots, fish scale spots, chromatic aberration, various spots and obvious wool marks are allowed. Note: The appearance quality inspection of imported paper is carried out in accordance with the provisions of ZBY32033-90.

| Physical Properties

Key point: Different paper requirements are different according to the classification

Newsprint: Newsprint requires paper to be soft and compressible, and the paper surface should have greater absorbency. To ensure that the printing ink can dry quickly during the printing process. It is required that the two sides of the paper are smooth, the thickness is consistent, the opacity is good, the printing is free of lint, does not paste the plate, the pattern is clear, and there is no perspective defect. For the roll paper, the two ends of the roll are required to have the same tightness, few joints, and good tensile strength, so as to meet the printing requirements of high-speed rotary printing machines.

Quality requirements for coated paper: smoothness. The paper surface must be very smooth, so that it can be in full contact with the surface of the screen copper plate during printing, so as to obtain fine and clear thin line patterns, which are realistic in shape and pleasing to the eye.

Whiteboard paper: Whiteboard paper generally requires tight texture, smooth surface, consistent thickness, no lint on the paper surface, good absorbency and small stretch rate to meet the requirements of multi-color overprinting. In order to meet the requirements of box making, whiteboard paper should have the characteristics of high stiffness and strong folding resistance.

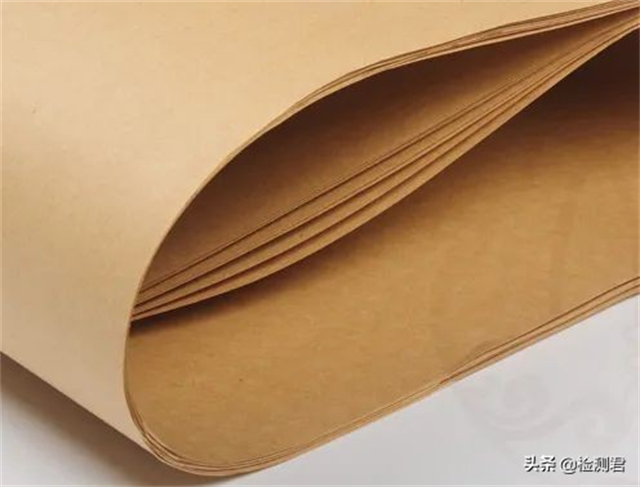

Kraft cardboard: Kraft cardboard is a cardboard specially used for the outer packaging of commodities, so the texture of the paper must be tough, and the bursting strength, ring compressive strength and tearing degree must be high. In addition, it should have high water resistance, so that the strength will not be greatly reduced due to a large amount of moisture absorption, resulting in damage to the carton during ocean transportation or cold storage. It should also have a certain smoothness for the kraft cardboard that needs to be used for printing.

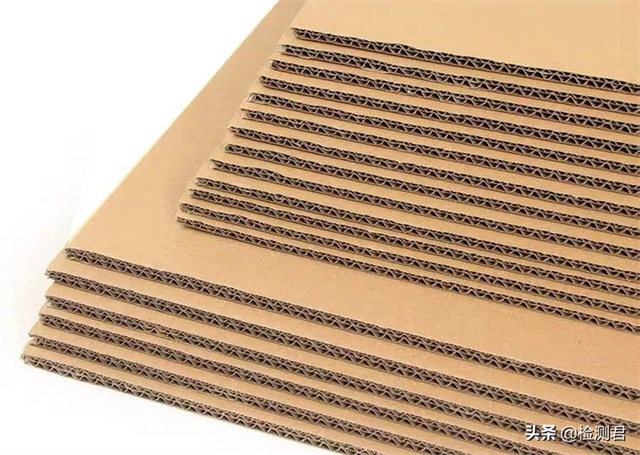

Corrugated base paper: Corrugated base paper requires good fiber bonding strength, smooth paper surface, and high tightness and stiffness. A certain degree of elasticity is required to maintain the shock-proof and pressure-resistant capacity of the produced carton. Therefore, bursting strength and ring compressive strength (or flat compressive strength) are the main indicators reflecting the strength of corrugated base paper. In addition, the moisture index should also be controlled. If the moisture content is too small, the paper will be brittle, and cracking will occur during the corrugating process. Excessive water content will bring difficulties to processing. Generally, the moisture content should be around 10%.

Cellophane: Cellophane is transparent in color, bright in paper surface, uniform in thickness, soft and stretchable. It will swell and become softer after being soaked in water, and shrink naturally after drying. In addition, due to the parallel arrangement of cellulose microcrystals in the longitudinal direction, the longitudinal strength of the paper is large, and the transverse direction is small, and if there is a crack, it will be broken by a very small force. Cellophane has the properties of impermeability, oil impermeability and water impermeability.

Offset printing paper: Offset paper is used for multi-color overprinting. In addition to requiring good whiteness and less dust, it has higher requirements for paper tightness, tensile strength and folding endurance. During printing, the surface of the paper does not shed lint, powder, or print through. It has the same requirements as coated paper.

03

Defect description and judgment

| Sales Packaging

Focus: Packaging and packaging methods

The defects and judgment standards related to the sales and packaging of paper products are as follows:

Defect description fatal serious minor product packaging improperly /*/

| Labeling/Marking/Printing

Focus: Labels, printing for sales packaging and products

Defect Description Fatal Serious Minor Product marketed in Europe and the US: No ingredient information *// Product marketed in the US: No country of origin information *// Product marketed in the US: No manufacturer name/registration number* //

| Production process

Key point: Whether the qualified paper is damaged, etc.

The defects and judgment criteria related to the production process are as follows:

Defect Description Fatal Severe Minor Paper Damage etc./*/spots/**holes/perforations/*/folds/wrinkles/**breaks/*/rips/*/folded corners/**dirty spots/**seersucker /**Pulp blocks and other hard blocks/**

| Post-press product inspection

Focus: Post-printing product spots, wrinkles, etc.

The defects and judgment standards related to post-press products are as follows:

Defect description fatal severe minor mottled /**wrinkled/**carbureted and water/**broken page*//less page*//

| Appearance

Key points: Appearance of wool marks, etc.

Appearance-related defects and judgment criteria are as follows:

Defect Description Fatal Severe Minor Felt Marks/**Couch Roll Shadow Marks/**Gloss Streaks/**

04

Testing on the spot

During the inspection of paper products, the following on-site tests are required:

| Product weight check

General Inspection Guide for Paper Products

Key point: gram weight checks whether the gram weight is sufficient

Test Quantity: At least 3 samples for each style.

Inspection requirements: Weigh the product and record the actual data; check according to the weight requirements provided or the weight information and tolerances on the product packaging materials.

| Paper Thickness Check

Key point: Whether the thickness meets the requirements

Test Quantity: At least 3 samples per style.

Inspection requirements: make product thickness measurements and record actual data; check according to the thickness requirements provided or the thickness information and tolerances on the product packaging materials.

Post time: Aug-04-2022