Daily-use ceramics generally refer to utensils in people’s daily life, such as tableware, tea sets, wine sets or other utensils. Because of the huge market demand, as an inspector, there are many opportunities to come into contact with such products. Today, I will share with you some knowledge about the inspection of daily-use ceramics.

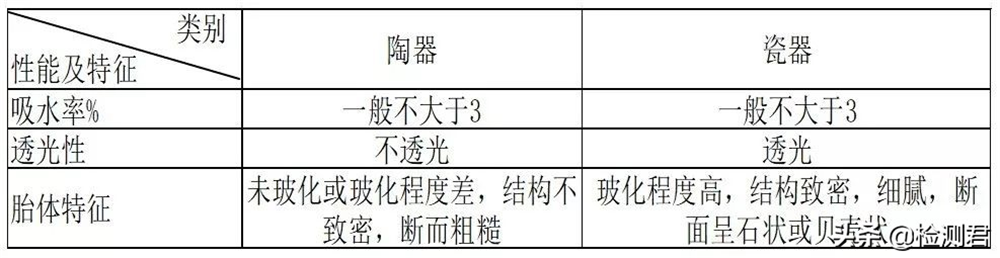

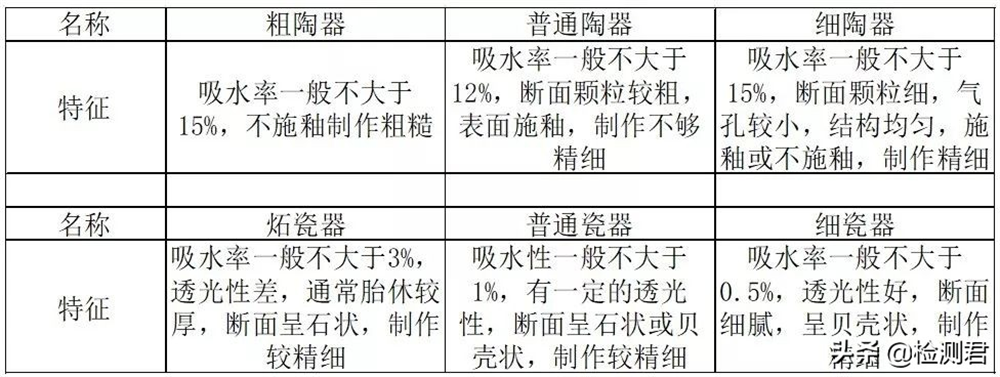

Difference Between Pottery and Porcelain

The difference between various types of ceramics

Inspection of packaging

First of all, the packaging inspection should be carried out according to the specific agreement signed by both parties. The outer packaging should be firm, and the inner lining should be made of shock-proof material; the parts of a product, such as the teapot and the lid, should be separated by soft paper. Outside the packing box (basket), there should be signs of “fragile items” and “moisture-proof items”.

After unpacking, you should check whether there is any damage and the number of pieces is short, and whether the product name and model specifications are consistent with the agreement. Fine porcelain should also check its completeness, such as whether the total number of fine porcelain tableware in a complete set (commonly known as how many heads) is correct.

Appearance defect inspection

1. Deformation: refers to the shape of the product that does not conform to the specified design.

2. Crooked mouth and ear handle: The height of the mouth and ear handle is uncomfortable and skewed.

3. Pimple: Refers to the raised tumor-like solid shape of the underglaze body.

4. Bubble: refers to the hollow bubble that is raised on the underglaze body.

5. Slag: Refers to the defects caused by the remaining mud and glaze residue on the blank that have not been removed.

6. Lack of mud: refers to the phenomenon that the green body is incomplete.

7. Glaze bubble: refers to the small bubbles on the surface of the glaze.

8. Blister edge: refers to a series of small bubbles appearing on the edge of the product mouth.

9. Blank explosion: Refers to the local peeling caused by improper moisture control before the blank enters the kiln.

10. Fried glaze: refers to the phenomenon of cracking on the glazed surface of the product.

11. Cracks: refers to the striate defects formed by the cracking of blanks and glazes, which are divided into three types. The first is a crack covered by the glaze, called a yin crack. The second is that the glaze is cracked and the body is not cracked, which is called glaze cracking. The third is that both the body and the glaze are cracked, which is called the cracking of both the body and the glaze.

12. Molten hole: refers to the hole produced by the melting of the fusible material during the firing process.

13. Spots: refers to the colored stains on the surface of the goods, also known as iron spots.

14. Pores: refers to the small holes (or brown-eyed pig pores, pinholes) present on the glaze surface.

15. Slag falling: refers to the saggar ash and other slag particles adhered to the glazed surface of the product.

16. Bottom edge sticky slag: refers to the small slag particles sticking to the edge of the foot of the product.

17. Needle point: the trace left by the support on the product.

18. Sticky scar: the defect formed by the bonding between the green body and the foreign object during firing.

19. Fire thorn: The rough brown surface caused by the fly ash in the flame.

20. Lack of glaze: Refers to the partial deglazing of the product.

21, orange glaze: refers to the glaze similar to orange peel.

22. Mud glaze strand: refers to the strand-like phenomenon of the green body and the glazed surface being partially raised.

23. Thin glaze: Refers to the glaze layer on the surface of the product, which forms an image that the glaze surface is not bright.

24. Dirty color: refers to the appearance of variegated colors on the surface of the product that should not be present.

25. Incorrect color: refers to the uneven color of the same pattern or the phenomenon of lack of light caused by lack of fire.

26. Lack of lines: refers to the defects of lines and edges decorated with lines.

27. Lack of picture: Refers to the phenomenon of incomplete picture and incorrect color.

28. Baked flower sticky glaze: refers to the colored stains and glaze damage on the glazed surface of the product during the baking process.

29. Dirty bottom feet: Refers to other impurities sticking to the bottom feet and discoloration.

30. The color difference of the joint mud of the mouth and ear: The color of the joint mud of the mouth and ear is inconsistent with the product itself.

31. Gypsum dirty: refers to the heterochromatic phenomenon of the green body due to the adhesion of gypsum.

32. Blue Gold: The bluish phenomenon caused by the metal being too thin.

33. Smoked: refers to the appearance of gray, black and brown in part or all of the product.

34. Yin yellow: refers to the partial or complete yellowing of the product.

35. Glaze scratches: refers to the phenomenon of streaks and partial loss of gloss on the glazed surface of goods.

36. Bump: refers to the partial impact or mutilation of goods, also known as hard injury.

37. Rolling traces: refers to the arc-shaped traces produced in rolling or knife pressing.

38. Wavy pattern: refers to the wavy pattern presented by the uneven glaze of the product.

Physical and chemical index test

1. Water absorption test of daily-use ceramics

2. Inspection of thermal stability of household ceramics

3. Whiteness of daily ceramics

4. Inspection of lead and cadmium dissolution of daily-use ceramics.

Daily Fine Porcelain Inspection

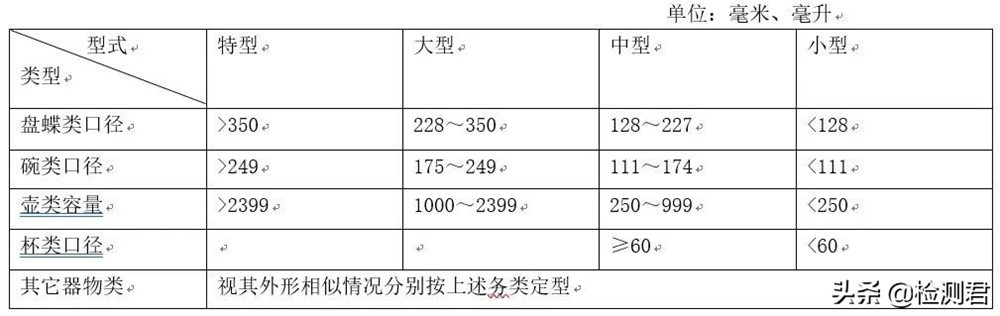

1. Specifications of fine porcelain for daily use

Product specifications are divided into special, large, medium, and small. The specific content is shown in the table:

2. Classification of fine porcelain for daily use

Daily fine porcelain is divided into four grades according to the appearance quality, and the specific requirements are as follows:

No more than 4 kinds of defects per product for first-class products;

Second-class products shall not exceed 5 defects per product;

Each product of the third-class product shall not exceed 6 kinds of defects;

Each product of Grade 4 shall not have more than 7 kinds of defects;

In addition, according to the standard, it is also required:

1. The water absorption rate should not exceed 0.5%.

2. The thermal stability requirements, from 200 ℃ into 20 ℃ water, the heat exchange will not crack once (bone china is not limited).

3. The whiteness of white porcelain shall not be lower than 65%, except for products with blue glaze and special color style.

4. The dissolution of lead on the contact surface with food is not more than 7PPM, and the dissolution of cadmium is not more than 0.5PPM.

5. Diameter tolerance. For diameters equal to or greater than 60 mm, allow from +1.5% to -1%; for diameters less than 60 mm, allow ±2%.

6. When the pot is tilted at 70 degrees, the lid must not fall off. When the lid is moved to one side, the distance between the lid and the spout must not exceed 3 mm. The mouth of the spout should not be lower than 3 mm from the spout.

7. The glaze color and picture color of a set of products should be basically the same, and the specifications and sizes should be commensurate.

8. No frying glaze, bumping, cracking and leakage defects are allowed.

Daily fine pottery inspection

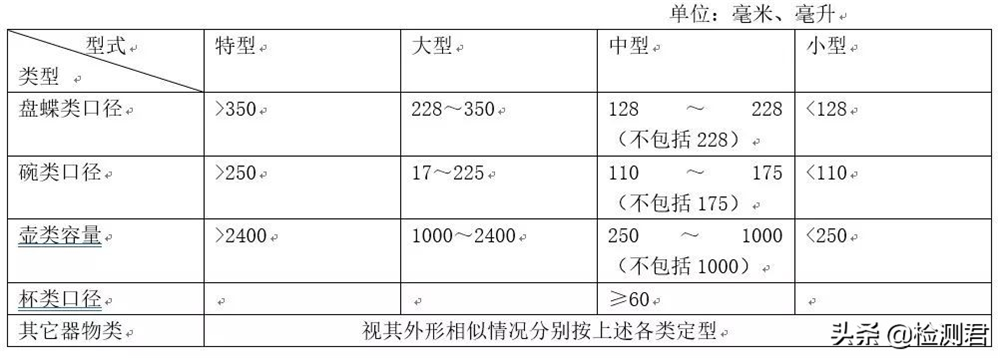

1. Specifications of daily fine pottery

Product specifications are divided into special, large, medium, and small. The specific content is shown in the table

2. Grading of daily fine pottery

Daily fine pottery is divided into three grades according to the appearance quality, the specific requirements are as follows:

First-class products shall not exceed 5 defects per product;

Second-class products shall not exceed 6 defects per product;

Each product of the third-class product shall not exceed 8 kinds of defects;

In addition, the standard stipulates that:

1. The tire quality is dense, and the water absorption rate does not exceed 15%.

2. The glaze surface is smooth and the color is pure.

3. Thermal stability requirements, from 200 ℃ into 20 ℃ water, the heat exchange will not crack once.

4. The product must be flat and stable when placed on a flat surface.

5. Tolerance of product diameter, the tolerance is +1.5% to 1% for the diameter greater than or equal to 60 mm, and the tolerance is ±2% for the diameter less than 60 mm.

6. The size of the lid and mouth of all covered products must be appropriate.

7. The product is not allowed to have frying glaze, bumping, cracking and leakage defects, and there are no opening and cracking bubbles at the edge of the mouth and the corners.

8. The glaze color, picture and gloss of the complete set of products should be basically the same, and the specifications and sizes should be commensurate.

9. The dissolution of lead on the contact surface with food is not more than 7PPM, and the dissolution of cadmium is not more than 0.5PPM.

Post time: Aug-16-2022