Children's furniture inspection includes quality requirements and quality inspection of children's tables and chairs, children's cabinets, children's beds, children's sofas, children's mattresses and other children's furniture.

一 . Appearance inspection of children’s furniture

1. Appearance inspection of wooden parts of children’s furniture

-No through cracks;

-No insect infestation;

-The exterior should be free of decay, and the area of slight decay on the interior should not exceed 20% of the area of the part;

-The appearance and materials used for storing items should be free of resin pockets;

-The width of the exterior knots should not exceed 1/3 of the material width, and the diameter should not exceed 12 m (except for special design requirements);

- Dead joints, holes, jackets, resin channels, and gum channels should be repaired (defects with a maximum single length or diameter less than 5 mm are not counted). After repair, the number of defects should not exceed 4 on the outside and 6 on the inside (design Except as required);

-Other minor material defects such as cracks (except through cracks), blunt edges, etc., should be repaired.

2. Appearance inspection of artificial panels for children’s furniture

-There should be no dry flowers or wet flowers on the appearance

-The area of dry flowers and wet flowers on the inner surface does not exceed 5% of the board surface

-On the same board surface, one place is allowed, with an area of 3mm~3mm.

There should be no obvious scratches on the surface.

-There should be no obvious indentation on the appearance

-The appearance should have no obvious color difference

-The appearance should be free of bubbling, cracking and delamination.

3. Appearance inspection of children’s furniture hardware

-Electroplated parts: The surface of the coating should be free of rust, burrs, and exposed bottoms; the surface of the coating should be smooth and flat, and should be free of blistering, yellowing, spots, burns, cracks, scratches, and bumps, etc.

-Sprayed parts: The coating should be free of spray leakage and rust; the coating should be smooth and even, consistent in color, and free of sagging, pimples, wrinkled skin, flying paint, etc.

-Metal alloy parts: There should be no rust, oxide film peeling, cutting edges, sharp edges; the surface should be fine and there should be no cracks, burrs, black spots, etc.

-Welded parts: The welded parts should be firm, and there should be no desoldering, false welding, or welding penetration; the welds should be uniform, and there should be no defects such as burrs, sharp edges, spatter, cracks, etc.

4. Appearance inspection of glass parts of children’s furniture

The exposed periphery should be edged, and the firmly installed glass should be clean and smooth, without defects such as cracks, scratches, lumps, and pitting.

5. Appearance inspection of plastic parts of children’s furniture

The surface of plastic parts should be smooth and clean, without cracks, wrinkles, stains, or obvious color differences.

6. Appearance inspection of children’s furniture packages

The spliced symmetrical patterns of the covered fabrics should be complete; the pile directions of the velvet fabrics in the same part should be consistent; there should be no obvious color difference. The covered fabric should not have scratches, color stains, oil stains, fluffing, or pilling.

The surface of the soft cover should be:

1) flat, full, and evenly tight, with no obvious wrinkles;

2) symmetrical and technical wrinkles that should be well-proportioned and well-organized.

Soft surface inlaid threads should:

1) be smooth and straight;

2) be symmetrical at the rounded corners;

3) have no obvious floating threads, obvious skipped stitches or exposed thread ends.

Exposed bubble nails:

1) The arrangement should be neat and the spacing is basically equal;

2) There should be no obvious flattened or peeling nails.

7. Children’s furniture carpentry inspection

The non-interconnected surfaces of artificial panel components should be edge-sealed or painted. Boards or components should not have burrs, edges or corners where they come into contact with the human body or where objects are stored. The surface of the plate or component should be smooth, and the chamfers, fillets, and round lines should be consistent. There should be no degumming, bubbling or cracking in the veneer, edge sealing and wrapping. The veneer should be tight and smooth, and there should be no obvious glue penetration, plug corners, and joints between parts and components should not be broken. The combination of parts should be tight and firm. The installation of various accessories and connectors should not include missing pieces or missing nails (except for reserved holes and optional holes).The installation of various accessories should be tight, smooth, straight and firm, and the joints should be free of cracks or looseness.

The opening and closing parts should be flexible to use after installation. The engraved pattern should be uniform, clear, and well-defined, and the symmetrical parts should be symmetrical. There should be no missing corners at convex and large digs, bridges, edges, and arcs. The bottom of the shovel should be flat, and there should be no hammer marks or burrs on any part. The number of defects per item shall not exceed 4. The linear shape of the turned wood should be consistent, the concave and convex steps should be even, the symmetrical parts should be symmetrical, the turning lines should be clear, and there should be no stubble, knife marks, or sand marks on the processed surface. The number of defects per item shall not exceed 4. Furniture locks should be locked in place and open flexibly. The casters should be flexible to rotate or slide.

8. Appearance inspection of paint film on children’s furniture

Like-colored parts should have similar shades. There should be no fading or discoloration. The coating should not be wrinkled, sticky or leaky. The coating should be smooth, clear, without obvious particles or edge swelling; there should be no obvious processing marks, scratches, cracks, haze, white edges, white spots, bubbling, oily white, sagging, shrinkage holes, bristle, etc. Accumulated powder and debris. The number of defects per item shall not exceed 4.

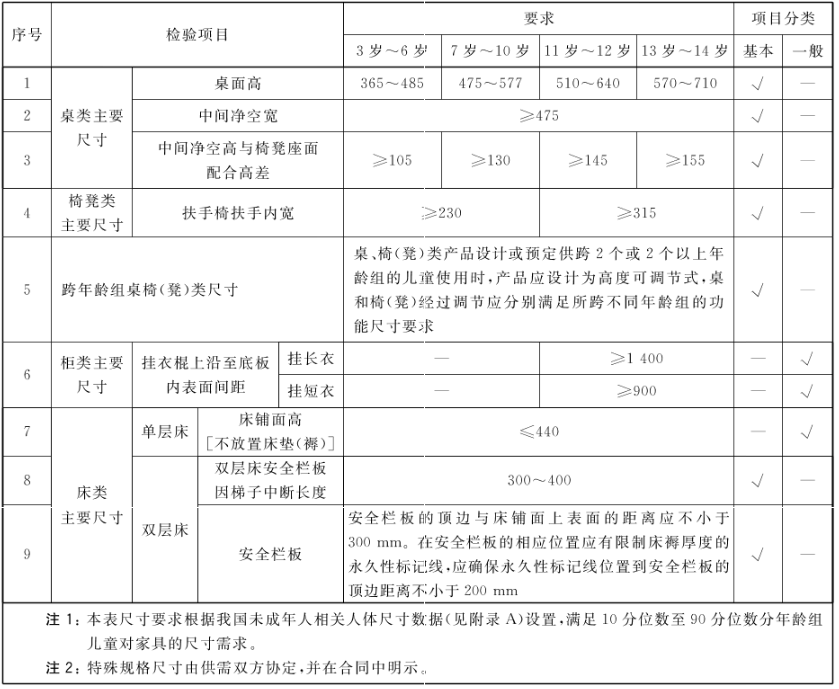

二 Children's furniture size inspection

Main size requirements for children's furniture:

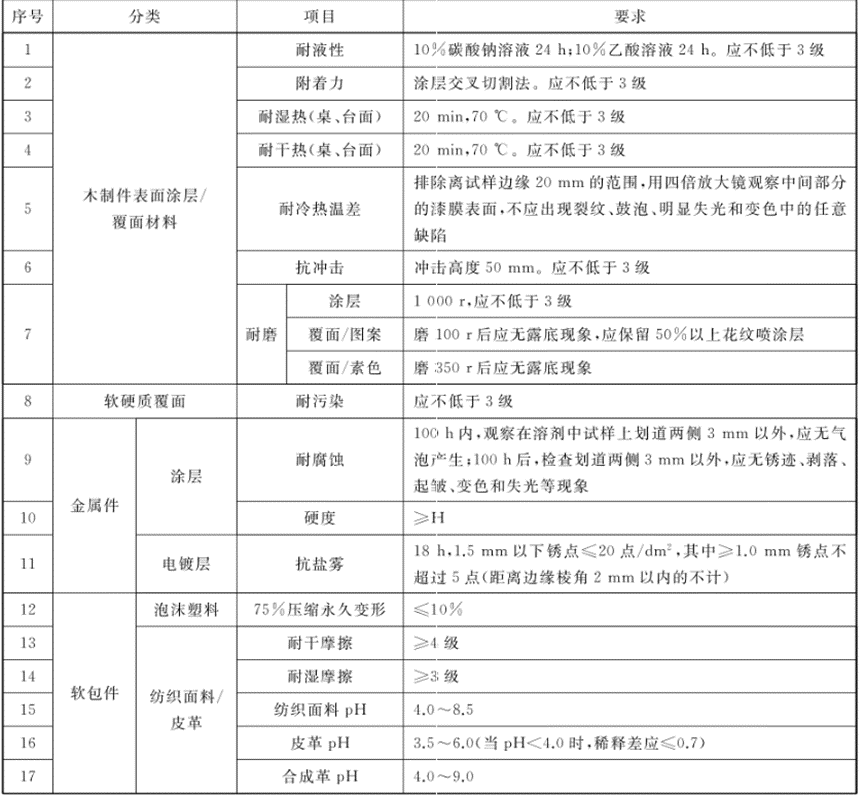

三 Physical and chemical performance testingof children's furniture

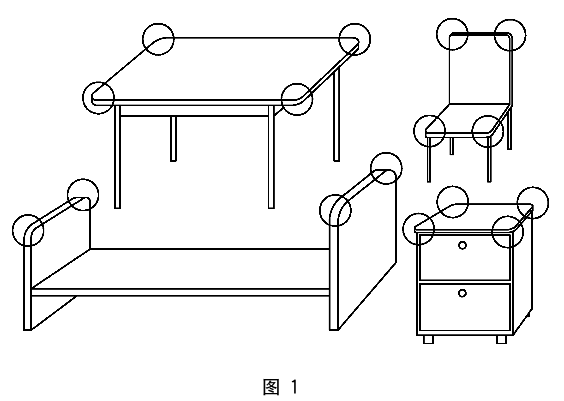

四 Children's furniture structural inspection

1.Outside corner

The dangerous outer corners of children's furniture that are accessible under normal use (see the circled position in Figure 1) should be rounded, with a radius of not less than 10 mm, or a rounding arc length of not less than 15 mm.When the product instructions clearly state that the product needs to be placed against the wall and connected to the wall, the outer corner of the product on the wall side does not need to be rounded.

2. Accessible dangerous sharp edges

The edges of accessible rigid materials on the product are tested as sharp edges and should not be hazardous sharp edges.Without the use of special tools, the bolt threads on the product expose an accessible edge simply by turning the knob, and this edge should also pass the sharp edge test.

3. Accessible dangerous sharp points

The points of accessible rigid materials on the product are tested as sharp points and should not be hazardous sharp points.

4. Dangerous protrusions

The product should not have dangerous protrusions. If there are dangerous protrusions, they should be protected in appropriate ways. For example, bend the end or add a protective cap or cover to effectively increase the area that may come into contact with the skin.

5. Holes, gaps and openings should meet the following requirements:

For holes, holes and gaps in the rigid material of the product with a depth exceeding 10 mm, the diameter or gap shall be less than 7 m or greater than or equal to 12 mm according to the test; the openings of all accessible tubular parts on the product shall be closed with a sealing cover or cap; Conduct a tensile test on the protective parts to ensure they do not fall off.

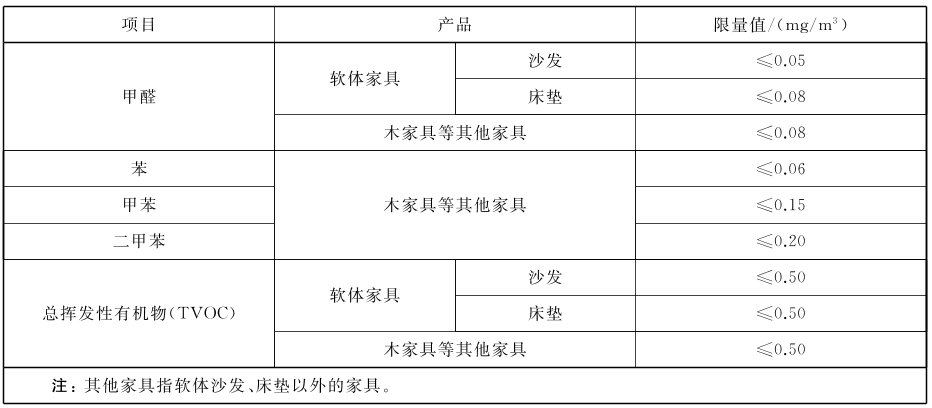

五 Children's furniture formaldehyde, benzene, toluene, xylene TVOC emission and other substance limit inspection

Formaldehyde, benzene, toluene and xylene TVOC release requirements for children’s furniture:

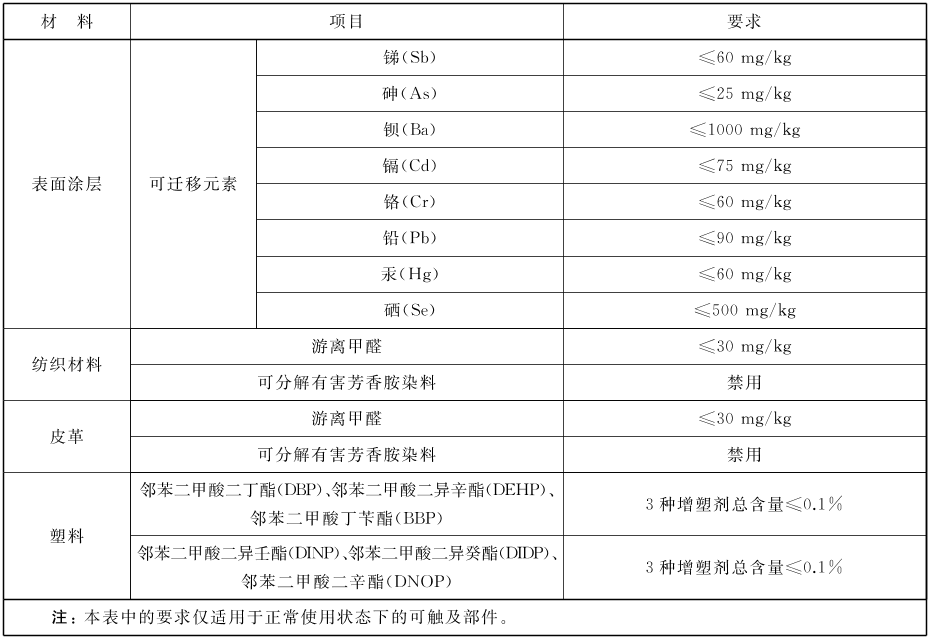

Limit requirements for other substances in children’s furniture:

六 Mechanical performance inspection of children’s furniture

After the mechanical performance test is carried out in accordance with the regulations, the following requirements should be met: no parts or components are broken, cracked or fallen off; no looseness, wear or deformation that affects the use function; some parts that should be firm should be pressed by hand, and there is no permanent looseness , such as degumming; the movable parts (doors, drawers, etc.) can be opened and closed flexibly; the hardware has no obvious deformation, damage or falling off; the upholstered furniture fabric has no damage, no springs are broken, the seams are not off-line, and the padding material is not damaged or displaced; During the stability test, the product did not tip over.

Post time: Dec-20-2023