As a critical link in pre-shipment quality control, carton drop testing directly determines whether products can withstand the rigors of international logistics—from factory loading to port unloading and final delivery.

By simulating accidental drops, collisions, and impacts during transit, this test verifies the protective performance of packaging, avoiding costly losses caused by product damage.

As a professional third-party inspection organization, TTS combines ISTA (International Safe Transit Association) standards and years of on-site testing experience to sort out 5 key points of carton drop testing, providing authoritative guidance for importers, exporters, and cross-border e-commerce enterprises.

1. Drop Height: Strictly Determined by Carton Gross Weight

The drop height is not arbitrary but is scientifically calibrated based on the total weight of the carton (including products and inner packaging).

The widely adopted ISTA 1A standard specifies clear parameters, with common weight-height correspondences as follows:

| Carton Gross Weight | Drop Height (Imperial) | Drop Height (Metric) |

| ≤21 lbs (~10 kg) | 30 inches | ~760 mm |

| 21–40 lbs (10–18 kg) | 24 inches | ~610 mm |

| 40–65 lbs (18–29 kg) | 18 inches | ~460 mm |

| 65–100 lbs (29–45 kg) | 12 inches | ~305 mm |

| 100–150 lbs (45–68 kg) | 8 inches | ~200 mm |

Note: For special products (e.g., fragile goods, precision instruments), drop height may be adjusted according to customized standards to simulate more extreme transit conditions.

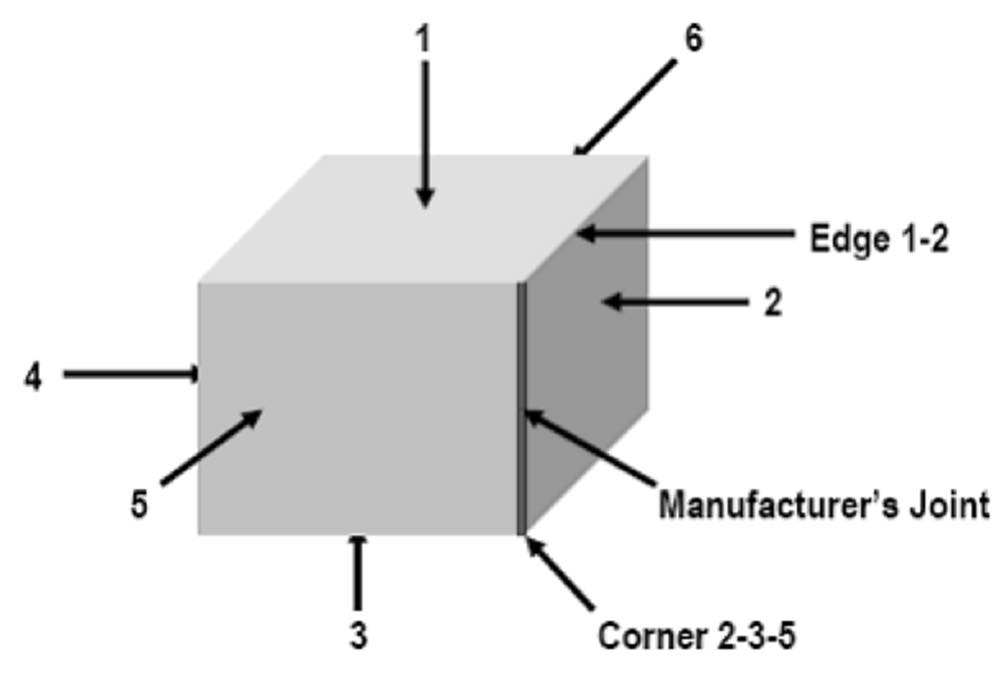

2. Test Sequence: 10 Standard Drops Cover All Critical Surfaces

To comprehensively evaluate packaging durability, the test requires 10 drops in a strict sequence, covering the carton’s most vulnerable parts:

- 1 drop on the weakest corner (usually the corner where the three lowest-strength edges meet);

- 3 drops on the three edges adjacent to this weak corner (each edge must bear the impact independently);

- 6 drops on the six faces of the carton (front, back, left, right, top, bottom), ensuring uniform stress distribution testing.

Any deviation from the sequence may lead to inaccurate results, so professional inspectors must operate in accordance with ISTA 1A procedures.

3. Result Evaluation: 4 Key Criteria for Pass/Fail Judgment

After completing the 10 drops, inspectors will open the carton and evaluate the result based on the following 4 criteria.

The test is deemed a failure if any of the following occurs:

- Outer carton: Visible cracks, tears, or deformation that affects structural integrity;

- Inner packaging: Damage to bubble wrap, foam, or other protective materials, losing cushioning effect;

- Product appearance: Scratches, dents, cracks, or other surface defects;

- Product functionality: Malfunction, inability to operate normally, or damage to key components.

A failed test indicates that the carton’s strength or packaging design is insufficient, and adjustments (e.g., increasing carton grammage, adding buffer materials) are required before shipment.

4. Burst Strength: The “Hidden Threshold” for Carton Durability

Burst strength (measured in PSI, pounds per square inch) is a core indicator of carton quality, referring to the maximum pressure the carton can withstand before breaking.

This value is usually printed on the carton’s bottom flap:

- Standard requirement: Cartons with a burst strength of ≥200 PSI can generally meet the durability needs of ISTA 1A drop tests;

- High-demand scenarios: For heavy products or long-distance transit, a burst strength of 250–300 PSI is recommended to enhance packaging resilience.

TTS inspectors will verify burst strength during pre-shipment inspections, ensuring cartons meet both drop test and long-term storage requirements.

5. ISTA 1A Standard: Beyond Drops—Comprehensive Transit Simulation

While drop testing is the focus, ISTA 1A is a comprehensive standard that also includes:

- Vertical impact test: Simulates impacts from stacking or dropping during loading/unloading;

- Incline impact test: Simulates collisions with other goods in transit;

- Random vibration test: Simulates vibration during truck, ship, or air transport.

These additional tests require professional equipment (e.g., vibration test benches, impact testers), making it impractical for most importers to conduct independent testing.

Third-party inspection organizations like TTS are equipped with certified laboratories and professional teams to provide full-cycle ISTA 1A compliance testing services.

Why Choose TTS for Pre-Shipment Carton Drop Testing?

- Authoritative Compliance: Strictly follow ISTA, ISO, and other international standards, with test reports recognized globally;

- On-Site Efficiency: Conduct tests at factories or warehouses, providing real-time results and rapid feedback;

- Customized Solutions: Tailor test plans for special products (fragile goods, oversized items) to meet specific industry requirements;

- Risk Mitigation: Identify packaging defects in advance, avoiding product damage, delivery delays, and customer complaints.

Carton drop testing is not just a formality but a key safeguard for product safety and brand reputation. By integrating professional pre-shipment inspection services, enterprises can effectively reduce logistics risks and ensure products arrive at their destinations intact.

For more details on carton drop testing, ISTA standard compliance, or customized pre-shipment inspection solutions, contact TTS Inspection today—we are committed to providing reliable quality assurance for your global trade!

Post time: Dec-16-2025