As the air frying pan has become increasingly popular in China, it has now spread all over the foreign trade circle and is widely favored by overseas consumers. According to the latest survey of Statista, 39.9% of American consumers said that if they plan to buy small kitchen appliances in the next 12 months, the most likely product to buy is air fryer. Whether it is sold to North America, Europe, or other regions, with the growth of sales, the air fryers have shipped thousands or even tens of thousands of products each time, and the inspection before shipment is particularly important.

Inspection of air fryers

Air fryers belong to household kitchen appliances. The inspection of air fryers is mainly based on IEC-2-37 standard: safety standard for household and similar electrical installations – special requirements for commercial electric fryers and deep fryers. If the following tests are not indicated, it means that the test method is in accordance with IEC international standards.

1. Transport drop test (not used for fragile goods)

Test method: Carry out drop test according to ISTA 1A standard. After 10 drops, the product and packaging should be free of fatal and serious problems. This test is mainly used to simulate the free fall that the product may be subjected to during transportation, and to investigate the ability of the product to resist accidental impact.

2. Appearance and assembly inspection

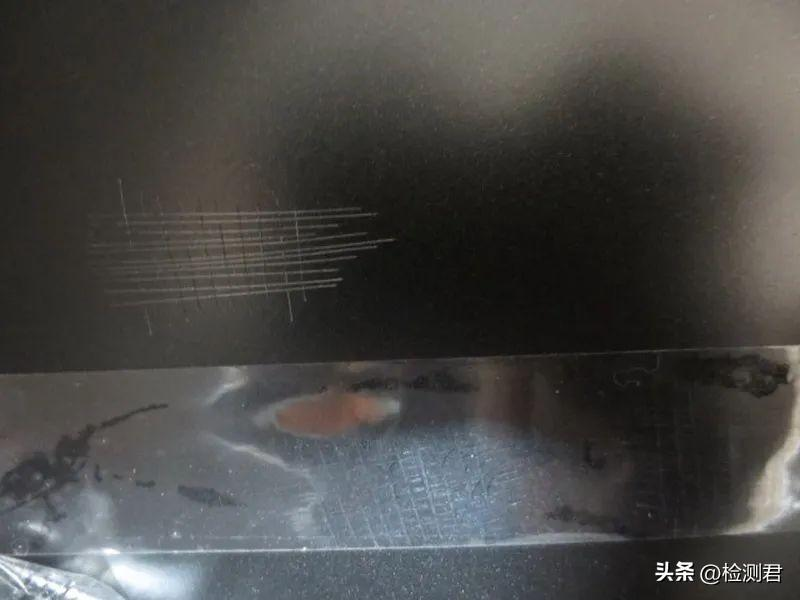

-The surface of electroplated parts must be smooth without spots, pinholes and bubbles.

-The paint film on the paint surface must be flat and bright, with uniform color and firm paint layer, and its main surface shall be free of defects affecting the appearance such as paint flow, stains, wrinkles and peeling.

-The surface of plastic parts shall be smooth and uniform in color, without obvious top white, scratches and color spots.

-The overall color shall be consistent without obvious color difference.

-The assembly clearance/step between the outer surface parts of the product should be less than 0.5mm, and the overall performance should be consistent, the fit strength should be uniform and appropriate, and there is no tight or loose fit.

-The rubber washer at the bottom shall be completely assembled without falling off, damage, rust and other phenomena.

3. Product size/weight/power cord length measurement

According to the product specification or the sample comparison test provided by the customer, measure the weight of a single product, the product size, the gross weight of the outer box, the size of the outer box, the length of the power cord and the capacity of the air fryer. If the customer does not provide detailed tolerance requirements, the tolerance of+/- 3% should be used.

4. Coating adhesion test

Use 3M 600 adhesive tape to test the adhesion of oil spray, hot stamping, UV coating and printing surface, and no 10% of the content can fall off.

5. Label friction test

Wipe the rated sticker with a cloth dipped in water for 15S, and then wipe it with a cloth dipped in gasoline for 15S. There is no obvious change on the label, and the handwriting should be clear, without affecting reading.

6. Full function test (including functions that must be assembled)

The switch/knob, installation, adjustment, setting, display and other functions specified in the manual shall be able to operate well. All functions shall comply with the declaration. For the air fryer, the function of cooking chips, chicken wings and other foods should also be tested. After cooking, the outer surface of the chips should be golden brown crisp texture, and the inside of the chips should be slightly dry without moisture, with good taste; After cooking the chicken wings, the skin of the chicken wings should be crisp and there should be no liquid flowing out. If the meat is too hard, it means that the chicken wings are too dry, and it is not a good cooking effect.

7. Input power test

Test method: measure and calculate the power deviation under rated voltage.

Under rated voltage and normal operating temperature, the deviation of rated power shall not be greater than the following provisions:

| Rated power(W) | Allowable deviation |

| 25<;≤200 | ±10% |

| >200 | +5% or 20W(Whichever is greater),-10% |

8. High voltage test

Test method: Apply the required voltage (the voltage is determined according to the product category or the voltage below the root) between the components to be tested, with the action time of 1s and the leakage current of 5mA. Required test voltage: 1200V for products sold in the United States or Canada; 1000V for Class I sold to Europe and 2500V for Class II sold to Europe, without insulation breakdown. Air fryers generally belong to Class I.

9. Startup test

Test method: the sample shall be powered by rated voltage, and work for at least 4 hours under full load or according to the instructions (if less than 4 hours). After the test, the sample shall be able to pass the high voltage test, function test, grounding resistance test, etc., and the results shall be free of defects.

10.Grounding test

Test method: the grounding test current is 25A, the time is 1s, and the resistance is not greater than 0.1ohm. American and Canadian market: the grounding test current is 25A, the time is 1s, and the resistance is not greater than 0.1ohm.

11. Thermal fuse function test

Let the temperature limiter not work, dry burn until the thermal fuse is disconnected, the fuse should act, and there is no safety problem.

12. Power cord tension test

Test method: IEC standard: pull 25 times. If the net weight of the product is less than or equal to 1kg, pull 30N; If the net weight of the product is more than 1kg but less than or equal to 4kg, pull 60N; If the net weight of the product is more than 4 kg, pull 100 newtons. After the test, the power line shall not produce more than 2mm displacement. UL standard: pull 35 pounds, hold for 1 minute, and the power cord cannot produce displacement.

13. Internal work and key parts inspection

Inspect the internal structure and key components according to CDF or CCL.

Mainly check the model, specification, manufacturer and other data of relevant parts. Generally, these components include: MCU, Relay, Mosfet, large electrolytic capacitor, large resistance, terminal, protective components such as PTC, MOV, etc.

14. Clock accuracy check

The clock should be set according to the instructions, and the actual time should be calculated according to the measurement (set at 2 hours). If there is no customer requirement, the tolerance of the electronic clock is+/- 1min, and the tolerance of the mechanical clock is+/- 10%

15. Stability check

UL standard and method: place the air fryer on a slope of 15 degrees from the horizontal plane as usual, place the power cord at the most unfavorable position, and the appliance shall not overturn.

IEC standards and methods: place the air fryer on an inclined plane 10 degrees from the horizontal plane according to the normal use, and place the power cord at the most unfavorable position without overturning; Place it on an inclined plane 15 degrees from the horizontal plane, and place the power cord in the most unfavorable position. It is allowed to overturn, but the temperature rise test needs to be repeated.

16. Handle compression test

The fixing device of the handle will withstand a pressure of 100N for 1 minute. Or support on the handle equal to 2 times the water volume of the whole pot and the weight of shell for 1 minute. After the test, the fixing system is free of defects. Such as riveting, welding, etc.

17. Noise test

Reference standard: IEC60704-1

Test method: under the background noise<25dB, place the product on a test table with a height of 0.75m in the center of the room, at least 1.0m away from the surrounding walls; Provide the rated voltage to the product and set the gear to make the product produce the maximum noise (Airfly and Rotisserie gears are recommended); Measure the maximum value of sound pressure (A-weighted) at a distance of 1m from the front, rear, left, right and top of the product. The measured sound pressure shall be less than the decibel value required by the product specification.

18. Water leakage test

Fill the inner container of the air fryer with water and leave it standing. The whole equipment should not leak.

19. Barcode scanning test

The barcode is printed clearly and scanned with barcode scanner. The scanning result is consistent with the product.

Post time: Mar-10-2023