The quality of bedding that is in direct contact with the skin will directly affect the comfort of sleep. Bed cover is a relatively common bedding, used in almost every household. So when inspecting the bed cover, what aspects need to be paid special attention to? We will tell you what key points need to be checked and which standards should be followed during inspection!

Inspection standards for products and packaging

The product

1) must have no safety issues during use

2) the appearance of the process must not be damaged, scratched, cracked, etc.

3) must comply with the laws and regulations of the destination country and the requirements of the customer

4) product structure and appearance , process and materials must meet customer requirements and batch samples

5) Products must meet customer requirements or have the same functions as batch samples

6) Labels must be clear and comply with legal and regulatory requirements

1) Packaging must be suitable and strong enough to ensure the reliability of the product transportation process

2) Packaging materials must be able to protect the product during transportation

3) Marks, barcodes and labels should meet customer requirements or batch samples

4) Packaging Materials should meet customer requirements or batch samples.

5) Explanatory text, instructions and related label warnings must be clearly printed in the language of the destination country.

6) Explanatory text, instruction descriptions must conform to the product and actual related functions.

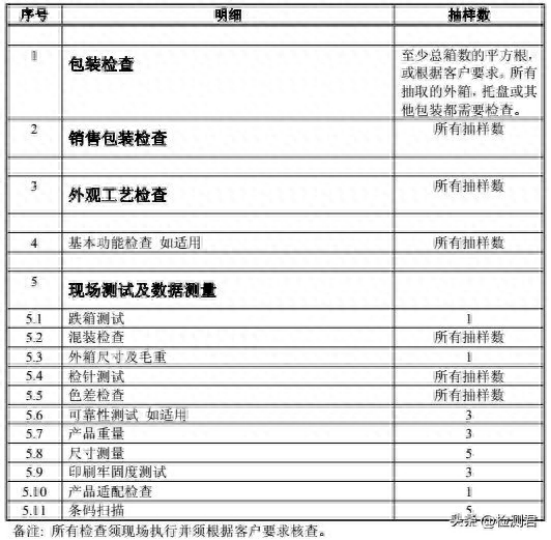

1) Applicable inspection standards ISO 2859/BS 6001/ANSI/ASQ – Z 1.4 Single sampling plan, normal inspection.

2) Sampling level

(1) Please refer to the sampling number in the following table

(2) If multiple models are inspected together, the sampling number of each model is determined by the percentage of the quantity of that model in the entire batch. The sampling number of this section is calculated proportionally based on the percentage. If the calculated sampling number is <1, select 2 samples for overall batch sampling, or select one sample for special sampling level inspection.

3) Acceptable quality level AQL does not allow serious defects Critical defectAQL xx Important defect standard Major DefectAQL xx Minor defect standard Minor Defect Note: “xx” indicates the acceptable quality level standard required by the customer

4) The number of samples for special sampling or fixed sampling , No unqualified items are allowed.

5) General principles for classification of defects

(1) Critical Defect: Serious defects, defects that cause personal injury or unsafe factors when using or storing the product, or defects that violate relevant laws and regulations.

(2) Major Defect: Functional defects affect the use or lifespan, or obvious appearance defects affect the sales value of the product.

(3) Minor Defect: A minor defect that does not affect the use of the product and has nothing to do with the sales value of the product.

6) Rules for random inspection:

(1) Final inspection requires that at least 100% of the products have been produced and sold in packaging, and at least 80% of the products have been packed into the outer carton. Except for special requirements of customers.

(2) If multiple defects are found on a sample, the most serious defect should be recorded as the basis for judgment. All defects should be replaced or repaired. If serious defects are found, the entire batch should be rejected and the customer will decide whether to release the goods.

4. Inspection process and defect classification

Serial number details Defect classification

1) Packaging inspection CriticalMajorMinor Plastic bag opening >19cm or area >10x9cm, no suffocation warning printed The origin mark is missing Or moisture, etc. XX Wrong material or incorrect packaging material X Wrong desiccant X Wrong hanger X Missing hanger X Missing buckle or other part Sex warning signs are missing or poorly printed

| 3) | Appearance process inspection |

X |

||

| Coils with risk of injury |

X |

|||

| Sharp edge and sharp point |

X |

|||

| Needle or metal foreign object |

X |

|||

| Small parts in children’s products |

X |

|||

| Odor |

X |

|||

| live insects |

X |

|||

| blood stains |

X |

|||

| Official language of destination country missing |

X |

|||

| Missing country of origin |

X |

|||

| Broken yarn |

X |

|||

| broken yarn |

X |

|||

| roving |

X |

X |

||

| Colored yarn |

X |

X |

||

| spun yarn |

X |

X |

||

| Big belly gauze |

X |

X |

||

| neps |

X |

X |

||

| Heavy needle |

X |

|||

| hole |

X |

|||

| Damaged fabric |

X |

|||

| stains |

X |

X |

||

| oil stains |

X |

X |

||

| water stains |

X |

X |

||

| Color difference |

X |

X |

||

| Pencil marks |

X |

X |

||

| Glue marks |

X |

X |

||

| Thread |

X |

X |

||

| foreign body |

X |

X |

||

| Color difference |

X |

|||

| fade |

X |

|||

| Reflective |

X |

|||

| Poor ironing |

X |

X |

||

| burnt |

X |

|||

| Poor ironing |

X |

|||

| compression deformation |

X |

|||

| Compression and stretching |

X |

|||

| Creases |

X |

X |

||

| wrinkles |

X |

X |

||

| fold marks |

X |

X |

||

| rough edges |

X |

X |

||

| Disconnected |

X |

|||

| line fall pit |

X |

|||

| Jumper |

X |

X |

||

| Pleating |

X |

X |

||

| Uneven stitches |

X |

X |

||

| Irregular stitches |

X |

X |

||

| Wave needle |

X |

X |

||

| Sewing is not strong |

X |

|||

| Bad return needle |

X |

|||

| Missing dates |

X |

|||

| Misplaced jujube |

X |

|||

| Missing seams |

X |

|||

| Seams are out of place |

X |

X |

||

| Sewing tension slack |

X |

|||

| Loose stitches |

X |

|||

| Needle marks |

X |

X |

||

| tangled sutures |

X |

X |

||

| Explode |

X |

|||

| Wrinkle |

X |

X |

||

| seam twisted |

X |

|||

| loose mouth/side | ||||

| seam fold |

X |

|||

| Seam folding direction is wrong |

X |

|||

| Seams are not aligned |

X |

|||

| seam slippage |

X |

|||

| Sewing in wrong direction |

X |

|||

| Sewing the wrong fabric |

X |

|||

| Not qualified |

X |

|||

| Not right |

X |

|||

| Missing embroidery |

X |

|||

| Embroidery misalignment |

X |

|||

| Broken embroidery thread |

X |

|||

| Wrong embroidery thread |

X |

X |

||

| Printing misalignment |

X |

X |

||

| printing mark |

X |

X |

||

| printing shift |

X |

X |

||

| fade |

X |

X |

||

| Stamping error |

X |

|||

| scratch |

X |

X |

||

| Poor coating or plating |

X |

X |

||

| Wrong accessory |

X |

|||

| Velcro is misplaced |

X |

|||

| Velcro uneven match |

X |

|||

| Elevator tag missing |

X |

|||

| Elevator label information error |

X |

|||

| Elevator label error |

X |

|||

| Poorly printed elevator label information |

X |

X |

||

| Elevator tag information is blocked |

X |

X |

||

| Elevator label is not secure |

X |

X |

||

| Labels are misaligned |

X |

|||

| Crooked mark |

X |

X |

5 Functional inspection, data measurement and on-site testing

1) Functional check: Zippers, buttons, snap buttons, rivets, Velcro and other components are not functioning properly. The zipper function is not smooth. XX

2) Data measurement and on-site testing

(1) Box drop test ISTA 1A Drop box, if safety and functionality are found to be lacking or important defects are found, the entire batch will be rejected

(2) Mixed packaging inspection and mixed packaging requirements do not meet customer requirements, the entire batch will be rejected

(3) The size and weight of the tail box must match the outer box printing, which is allowed. Difference +/-5%–

(4) The needle detection test found a broken needle, and the entire batch was rejected due to metal foreign matter.

(5) Color difference inspection is based on customer requirements. If there is no requirement, the following reference standards: a. There is color difference in the same piece. b. .The color difference of the same item, the color difference of dark colors exceeds 4~5, the color difference of light colors exceeds 5. c. The color difference of the same batch, the color difference of dark colors exceeds 4, the color difference of light colors exceeds 4~5, the entire batch will be rejected

(6) Zippers, buttons, snap buttons , Velcro and other functional reliability inspection tests for 100 normal uses. If the parts are damaged, broken, lose their normal function, reject the entire batch or cause defects during use.

(7) Weight inspection is based on customer requirements. If there is no requirement, define the tolerance +/-3% and reject the entire batch.

(8) Dimension inspection is based on customer requirements. If there is no requirement, record the actual found dimensions. Reject the entire batch

(9) Use 3M 600 tape to test the printing fastness. If there is printing peeling off, a. Use 3M tape to stick to the printer and press firmly. b. Tear off the tape at 45 degrees. c. Check the tape and printing to see if there is printing peeling off. Reject the entire batch

(10 ) Adaptation check Check whether the product is adapted to the corresponding bed type Reject the entire batch

(11) Barcode scanning Use a barcode scanner to read the barcode, whether the numbers and reading values are consistent Reject the entire batch Remarks: The judgment of all defects is only for For reference, if the customer has special requirements, it should be judged according to the customer’s requirements.

Post time: Sep-21-2023