The cheongsam is known as the quintessence of China and the national dress of women. With the rise of the "national trend", the retro + innovative improved cheongsam has become the darling of fashion, bursting with new colors, and gradually entering the public's daily life, becoming a popular fashion item.

There are many theories about the origin of the cheongsam. Some believe that the cheongsam developed directly from the robes worn by flag girls in the Qing Dynasty. Others believe that the robes worn by Chinese women can be traced back to the Zhou, Qin, Han, Tang, Song, and Ming Dynasty.

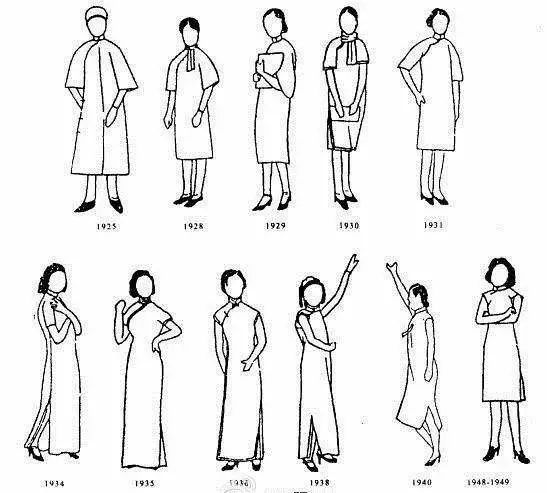

Regarding the evolution of cheongsam, the figure is roughly as follows:

Cheongsams come in various styles and are classified in various ways. According to the collar type, there are general collar, penguin collar, impatiens collar, no collar, drop collar, bamboo leaf collar, horseshoe collar, etc. According to the placket, there are oblique placket, middle placket, semi-circular placket, etc. Snap button types include one-word button, phoenix tail button, pipa button, butterfly button, single-color button, two-color button, etc. According to the sleeve type, there are sleeveless, shaved shoulders, short sleeves, three-quarter sleeves, eight-quarter sleeves, long sleeves, narrow sleeves, bell sleeves, large bell sleeves, horseshoe sleeves, turned-back sleeves, etc.

Quality requirements for cheongsam

Judging the quality of a cheongsam requires comprehensive consideration of fabrics, workmanship and other aspects. Regarding the quality of cheongsam, the current national standard "GB/T 22703-2019 Cheongsam" clearly stipulates various quality requirements and indicators for cheongsam.

Fabric

Focus: Cheongsam fabric

fabric quality

The fabrics of cheongsam generally include brocade, damask, power spinning, hangro, silk, linen, tussah silk, spun silk, mulberry silk, castor silk, fragrant cloud yarn, silk, antique satin, plain crepe satin, georgette , gold jade satin, etc.

No matter what kind of fabric it is, it must be a fabric that meets the relevant quality requirements of the GB/T 22703-2019 standard, as shown below.

Lining

Focus: lining

quality

The lining of the cheongsam should be suitable for the fabric used and meet the relevant quality requirements of the GB/T 22703-2019 standard.

Excipients

Focus: excipients

Interlining, sutures, etc.

Interlining and shoulder pads: Interlining and shoulder pads should be used that are suitable for the performance of the fabrics used, and their quality should comply with the relevant provisions of the GB/T 22703-2019 standard;

Sutures: sutures, embroidery threads, etc. that are suitable for the performance of the fabrics, linings, and accessories used; button threads should be suitable for the color of the trip buttons; label stitching lines should be suitable for the background color of the trademark (decorative threads except)

Buttons, zippers and other accessories: Buttons (except decorative deductions), zippers and other accessories should be used that are suitable for the fabric used. Buttons, decorative buttons, zippers and other accessories should have a smooth surface, no burrs, chips, defects, and no accessible sharp points or sharp edges. The zipper should mesh well and flow smoothly.

Note: Accessible sharp points and sharp edges refer to sharp points and edges on the finished product that may cause harm to human skin under normal wearing conditions.

warp and weft direction

Focus: warp and weft direction

Skew degree

The bottom edge of the front body should not be turned upside down. The yarn skew of the fabric should not be greater than 3%.

Focus: color difference

Color difference level

The color difference between the collar, sleeve surface and the body should be higher than level 4, and the color difference in other surface parts should not be lower than level 4. The color difference of the lining should be no less than 3-4 levels.

Matching strips and squares

Focus: fabric strips

Plaid type

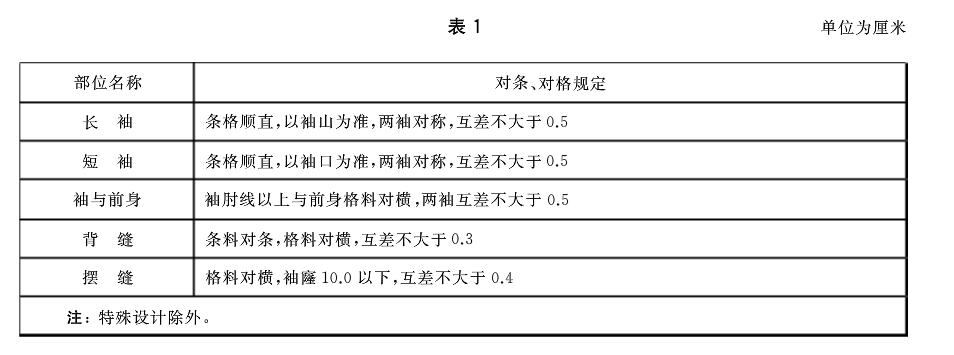

Fabrics with obvious strips and grids and widths of 1.0cm and above should be specified in Table 1.

For wool (velvet) and yin-yang fabrics, the whole body should be in the same direction.

For fabrics with special patterns, please refer to the main picture, and the whole body should be consistent.

Appearance defects

Focus: Appearance of cheongsam

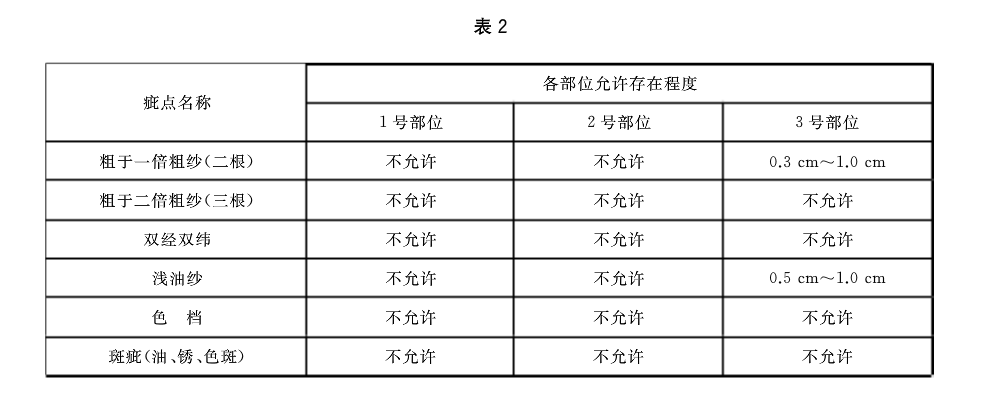

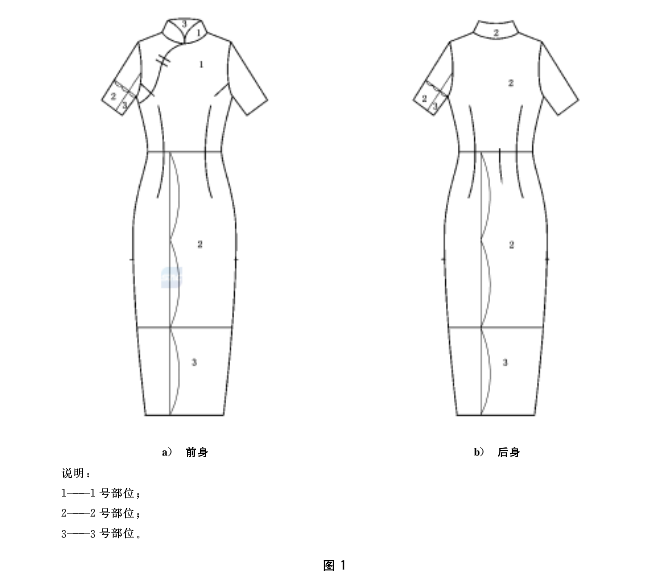

The allowable degree of defects in each part of the finished product should be specified in Table 2. The division of each part of the finished product is shown in Figure 1. Only one allowed level of defects is allowed for each part. Defects not listed in Table 2 shall refer to the similar defect provisions in Table 2 according to their shape.

sewing

Focus: Sewing

Craftsmanship

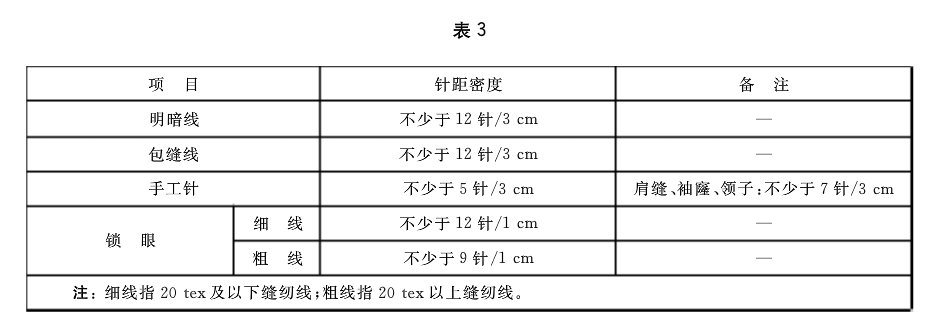

The stitch density should be specified in Table 3, except for special designs.

The sewing lines of each part should be straight, neat, flat and firm;

The bottom thread should be tight and tight, and there should be no jumpers or broken threads. There should be a back stitch at the lifting and lowering needles;

The collar should be flat, with appropriate elasticity and reinforcement at the collar;

The sleeves should be round and smooth, basically consistent from front to back;

The rolling strips and pressing strips should be flat and the width should be basically the same and smooth;

All exposed seams should be overlocked or raw edges should be folded cleanly;

The seam allowance at the upper collar should not be less than 0.5cm, the seam allowance at the piping should not be less than 0.3cm, and the seam allowance at other parts should not be less than 0.8cm;

The position of trademarks and durable labels should be correct and flat;

There should be no continuous skipped stitches or more than one single skipped stitch within 30cm of the sewing stitches in each part;

Decorations (embroidery, inlay, etc.) should be firm and flat;

The button loops and button heads of the flower buttons should be positioned accurately; firm and flat; neat and beautiful;

The slits on both sides should be symmetrical from left to right; the slits should be firm, the slits should be straight, and there should be no regurgitation, inward warping, or wrinkles;

The elasticity of the zipper should be straight and without wrinkles;

The finished product should not contain metal needles or metal sharp objects.

Allowable deviation of specifications and dimensions

Focus: Specifications and dimensions

Allowable deviation

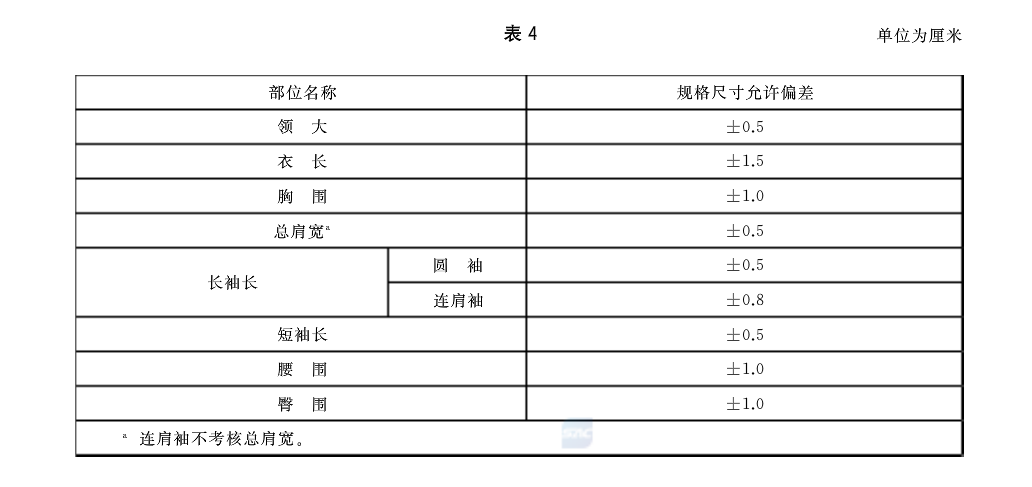

The allowable deviations in specifications and dimensions of the main parts of the finished product shall be as specified in Table 4.

Ironing

Focus: Ironing

All parts should be ironed, neat and tidy, without yellowing, water stains or shine;

There should be no degumming, glue seepage, wrinkling or blistering in the area where the adhesive lining is used. There should be no glue on the surface of each part.

Physical and chemical properties

Focus: Security

check

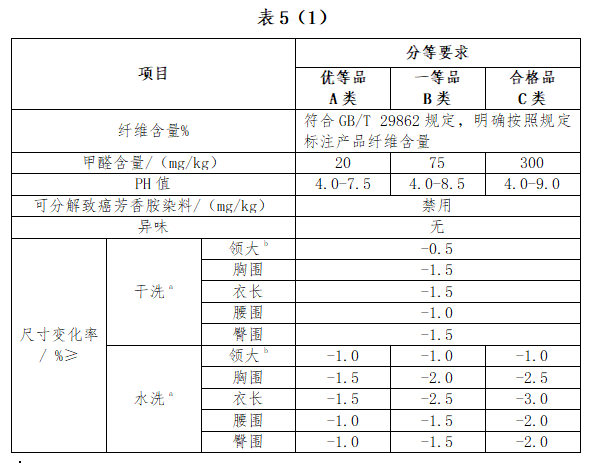

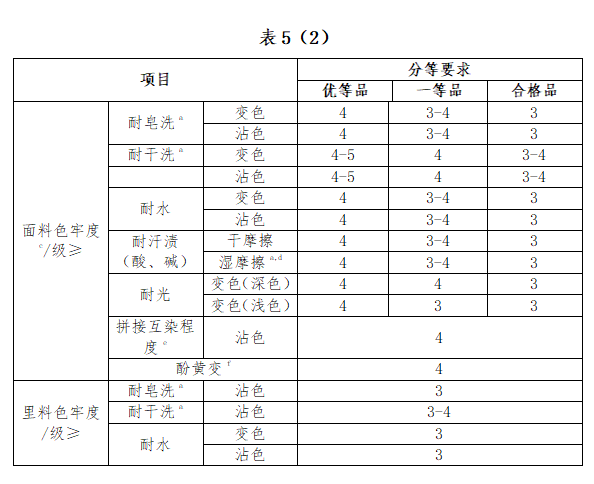

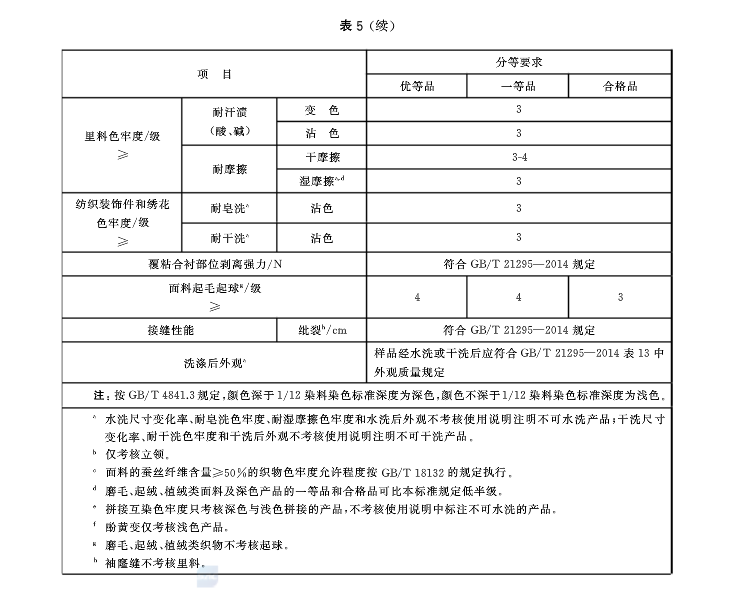

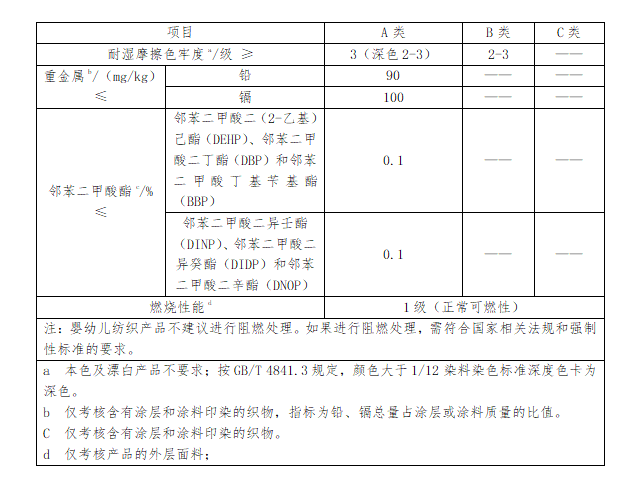

The physical and chemical properties of the finished product should be as specified in Table 5.

Among them, the safety performance of clothing worn by children over 3 to 14 years old should also comply with the regulations of GB 31701, as shown below:

Testing method

The various quality requirements of cheongsam require corresponding methods to inspect and determine whether they are qualified. In "GB/T 22703-2019 Cheongsam", corresponding regulations and explanations are also made for the inspection methods of cheongsam.

When inspecting cheongsam, the tools that need to be used include a tape measure (or ruler), a gray sample card for evaluating discoloration (i.e., a five-level gray sample card), a 1/12 dye dyeing standard depth color card, etc. The specific inspection items and methods are as follows:

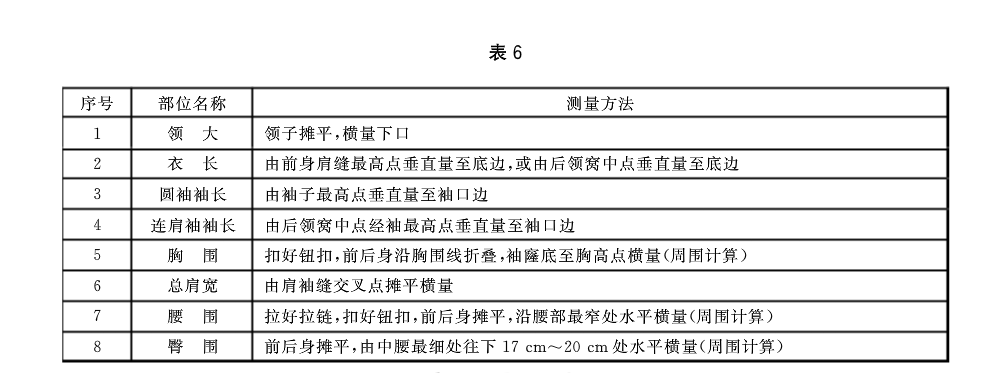

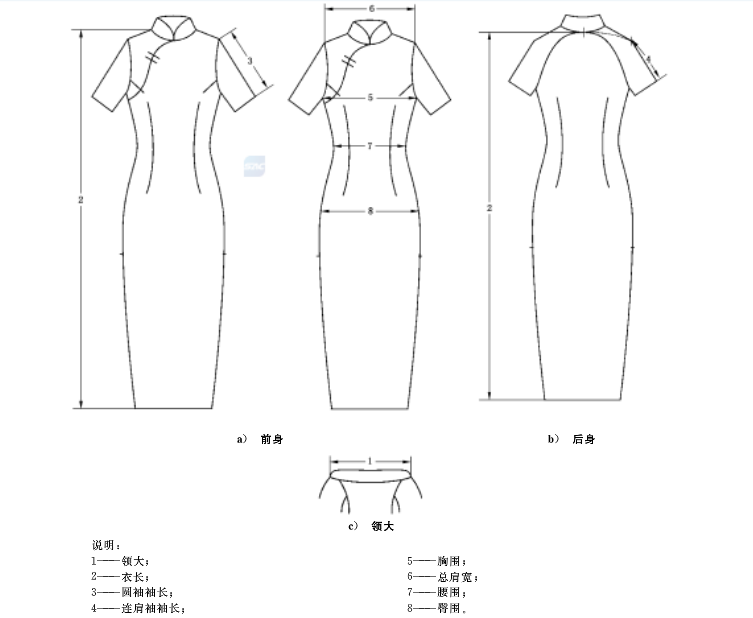

Finished product specification measurement

Focus: Measurement

Finished product size, etc.

The allowable deviations in specifications and dimensions of the main parts of the finished product are specified in Table 4, the measurement parts are shown in Figure 2, and the measurement methods are specified in Table 6.

Visual inspection

Focus: Appearance

Appearance defects

Appearance inspection generally uses light illumination with an illumination of not less than 600lx. Northern skylight illumination can also be used when conditions permit;

When evaluating the degree of color difference, the yarn direction of the evaluated parts should be consistent. The angle between the incident light and the fabric surface is approximately 45 degrees. The observation direction should be perpendicular to the fabric surface, and the distance should be 60cm for visual inspection. Compare with the GB/T 250 sample card;

When determining the allowable degree of defects, visually inspect from a distance of 60cm and compare with the standard photo of shirt appearance defects (GSB 16-2951-2012). If necessary, use a steel tape measure or ruler to measure;

The stitch density is measured at any 3cm on the finished sewing stitch (excluding thick and thin parts);

After measuring the skewness of warp and weft yarns, calculate the results according to the following formula;

S=d/W×100

S——Warp or weft yarn skew degree, %;

d——The maximum vertical distance between the warp or weft yarn and the ruler, in millimeters;

W——The width of the measuring part, in millimeters.

testing regulations

Inspection of finished cheongsam products is divided into factory inspection and type inspection. The timing of type inspection is based on the actual production situation or the provisions of the contract agreement, and is generally carried out when production is changed, production is resumed after a shutdown, or there are major changes in raw materials or processes.

"GB/T 22703-2019 Cheongsam" stipulates that the following rules need to be followed during cheongsam inspection:

Appearance quality grade and defect classification rules

Focus: Appearance

Quality defects

Appearance quality grade classification rules: Finished product quality grade classification is based on the existence of defects and their severity. The individual products in the sampling sample are graded based on the number of defects and their severity, and the batch grade is graded based on the number of defects in the single product in the sampling sample.

Classification of appearance defects: A single product that does not meet the requirements specified in this standard constitutes a defect. Defects are divided into three categories according to the degree of product failure to meet standard requirements and the impact on product performance and appearance:

Serious defects: Defects that seriously reduce the performance of the product and seriously affect the appearance of the product;

Major defects: Defects that do not seriously reduce the performance of the product or seriously affect the appearance of the product, but are serious defects that do not meet the requirements of the standard;

Minor defects: Defects that do not meet standard requirements but have a minor impact on the performance and appearance of the product.

Basis for judging appearance quality defects:

The appearance quality defects of finished products are determined as follows:

Excipients and accessories

Minor defect - the color and tone of the accessories are not suitable for the fabric;

Major defect - the performance of lining and accessories is not suitable for the fabric. The zipper is not smooth;

Serious defects - buttons and accessories fall off; metal parts are rusted; the surface of buttons, decorative buttons and other accessories is not smooth, has burrs, defects, defects, and accessible sharp points and sharp edges. Poor zipper engagement.

warp and weft direction

Minor defects - yarn direction deviation exceeds 50% or less specified in this standard; the bottom edge of the front body is warped;

Serious defect - the yarn direction skew exceeds the provisions of this standard by more than 50%.

Matching strips and squares

Minor defects - the number of lines and squares exceeds the provisions of this standard by 50% or less;

Serious defects - more than 50% of the items and squares exceed the requirements of this standard;

Serious defects - the fabric is not smooth and the direction of the whole body is inconsistent; special patterns are inconsistent in the direction.

Color difference

Minor defect - color difference is half a grade lower than specified in this standard;

Serious defect - the color difference is more than half a grade lower than that specified in this standard.

Defects

Minor defects - No. 2 and No. 3 parts exceed the requirements of this standard; (see the appearance defects section above for details)

Serious defect - Part No. 1 exceeds the requirements of this standard.

trademark

Minor defects - trademarks and durable labels are not straight, flat and obviously skewed;

Allowable deviation of specifications and dimensions

Minor defects - the allowable deviation of specifications and dimensions exceeds the provisions of this standard by 50% or less;

Major defect - the allowable deviation of specifications and dimensions exceeds the provisions of this standard by more than 50%;

Serious defect - the allowable deviation of specifications and dimensions exceeds the provisions of this standard by 100% and within.

Note 1: Defects not covered above can be determined according to the defect classification rules and similar defects as appropriate.

Note 2: Any missing work, missing order, or wrong order are serious defects. Missing parts are serious defects.

Sampling rules

Focus: Sampling

quantity

Sampling quantity by product batch:

——10 pieces for random inspection of 500 pieces or less;

——500 pieces to 1,000 pieces (including 1,000 pieces), 20 pieces will be randomly inspected;

——30 pieces will be randomly inspected for more than 1,000 pieces.

The physical and chemical performance inspection sampling is based on test needs, generally not less than 4 pieces.

Note 1: The above sampling standards are in accordance with "GB/T 22703-2019 Cheongsam", which is different from the AQL sampling standards commonly used in inspection work. In specific work, it can be executed according to the order requirements.

Decision rules

Focus: Judgment rules

How to judge

Appearance judgment of single piece (sample)

Excellent product: number of serious defects = 0, number of major defects = 0, number of minor defects ≤ 3

First-class product: number of serious defects = 0, number of major defects = 0, number of minor defects ≤ 5, or number of serious defects = 0, number of major defects ≤ 1, number of minor defects ≤ 3

Qualified product: number of serious defects = 0, number of major defects = 0, number of minor defects ≤ 8, or number of serious defects = 0, number of major defects ≤ 1, number of minor defects ≤ 4

Batch grade determination

Excellent product batch: The number of excellent products in the appearance inspection samples is ≥90%, the number of first-class products and qualified products is ≤10%, and no unqualified products are included. All physical and chemical performance tests meet the requirements for high-quality products.

First-class product batch: The number of first-class and above products in the appearance inspection sample is ≥90%, the number of qualified products is ≤10%, and no unqualified products are included. All physical and chemical performance tests have reached the first-class product index requirements.

Qualified product batch: The number of qualified products and above in the appearance inspection sample is ≥90%, and the number of unqualified products is ≤10%, but does not include unqualified products with serious defects. All physical and chemical performance tests meet the requirements for qualified product indicators.

Note: When the appearance sewing quality judgment is inconsistent with the physical and chemical performance judgment, it shall be judged as a low grade.

When the judgment number of each batch in the random inspection meets the corresponding grade requirements in 6.4.2, the batch of products is judged to be qualified; otherwise, it is judged to be unqualified.

Re-inspection regulations

If the judgment number of each batch in the random inspection does not meet the requirements of this standard or the delivery parties have objections to the inspection results, a second random inspection can be carried out. At this time, the random inspection quantity should be doubled. The retest result shall be the final judgment result.

Marking, packaging, transportation and storage

In addition to the quality requirements, inspection methods, and inspection rules for cheongsam, quality workers also need to pay attention to product marking, packaging, transportation, and storage.

"GB/T 22703-2019 Cheongsam" stipulates that marking, packaging, transportation and storage should be implemented in accordance with FZ/T 80002. details as follows:

logo

Focus: logo

Sign regulations

The transport packaging should indicate the product number, product name, model or specification, quantity, company name and address, etc. The packaging signs should be clear and eye-catching.

Package

Focus: packaging

Packaging materials, etc.

Packaging materials should be clean and dry, and materials that do not cause pollution to the natural environment or are recyclable should be selected. The heavy metal content in packaging materials should comply with the regulations of GB/T 16716.1;

Infant clothing and clothing product packaging that directly contacts the skin should use non-metallic products (except outer packaging boxes);

Paper packages should be folded correctly and packaged firmly;

Plastic bag packaging requirements: The specifications of the plastic bag should be suitable for the product, and the seal should be firm. Products should be put into plastic bags flat and with appropriate tightness. Use plastic bags with printed text and patterns. The text and patterns should be printed on the outside of the plastic bag, and the pigments should not contaminate the product. Products packaged with hangers should be straight and flat;

Carton packaging: The size of the carton should be suitable for the product, and the product should be packed in the box with appropriate tightness. Products packaged with hangers should be straight and flat.

transportation

Focus: Transportation

Transportation safety

When transporting product packages, they should be protected against moisture, damage and contamination.

storage

Focus: Storage

Storage conditions

Product storage should be moisture-proof, and woolen products should be moth-proof. Product packages should be stacked in the warehouse, which should be dry, ventilated, and clean.

Post time: Nov-24-2023