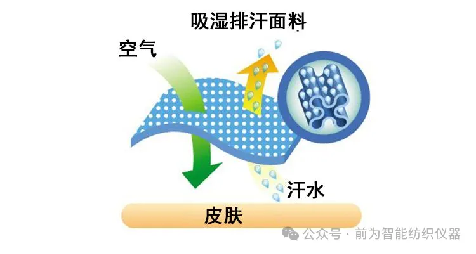

As the weather gets warmer and the temperature rises, clothes become thinner and wear less. At this time, the breath-ability of clothes is particularly important! A piece of clothing with good breath-ability can effectively evaporate sweat from the body, so the breath-ability of the fabric is directly related to the comfort of the fabric.

Application of breath-ability in textile industry

Clothing industry: Breath ability is one of the important indicators for evaluating the comfort of textiles. Especially when designing outdoor sportswear, sports shoes and other products, it is necessary to verify whether they can provide good breath ability through breath ability testing to achieve moisture absorption and perspiration. , Keep dry effect.

Home textiles: products such as bedding, curtains, furniture covers, etc. Air permeability testing can be used to determine the air permeability of these products and then evaluate their comfort and applicability.

Medical supplies: Medical textiles such as surgical gowns and masks need to have good breath ability to ensure that medical personnel can remain comfortable in a long-term working environment. Through breath ability testing, the gas exchange performance of a product can be determined to prevent bacterial and viral infections.

Sports equipment: Some sports equipment such as sports shoes, sports hats, etc. will also use breath ability testing to ensure their air circulation performance.

Applications of breath-ability in other industries

Automotive interior parts materials: Determine the air permeability and air resistance of automotive interior parts materials (such as polyurethane, PVC, leather, textiles, non-woven fabrics, etc.).

Building materials: Determine the air permeability of building materials (such as stone, concrete, etc.) to evaluate their ability to affect the air quality inside the building.

Packaging materials: Many special packaging materials (such as fresh-keeping packaging, etc.) need to have a certain degree of air permeability to ensure the quality of the packaging contents.

Electronic products: Some components of electronic products need to have good breathability to ensure the normal operation of electronic equipment.

Comparison of different test methods for breath-ability

Now, there are many standards and methods for fabric breath-ability testing. The following brings you the test standards and comparisons of air permeability of commonly used fabrics at home and abroad. These standards come from different countries or organizations, such as ISO, GB, BS, ASTM, etc. Individual standards may apply to different types of materials or products, such as nonwovens, textiles, etc. Different standards may use different testing principles, such as air flow method, water vapor transfer method, etc. Although most standards use similar testing principles, the specific test equipment may vary depending on the requirements of the standard.

1.ISO 9073-15 ISO 9237

Scope of application: Suitable for air permeability testing of non-woven materials, such as filter materials, thermal insulation materials and other fields. Test principle: The air flow method is used to measure the flow of gas through the sample to evaluate the breath-ability performance. Test equipment: The air permeability tester includes air source, test fixture, flow meter and other components.

2. GB/T 5453 GB/T 24218.15

Application scope: Used to evaluate the breath-ability performance of textiles, including fabrics, clothing, etc.

Test principle: Use the air flow method or water vapor transfer method to measure the rate of gas or water vapor passing through the sample to evaluate the breath-ability performance.

Testing equipment: Different testing methods may require different equipment. For example, the air flow method requires breath-ability testing equipment, and the water vapor transfer method requires humidity control equipment, etc.

3. BS 3424-16 BS 6F 100 3.13

Application scope: Used to evaluate the breath-ability performance of fabrics, such as fabrics, clothing, etc.

Testing principle: air flow method or water vapor transfer method is used.

Testing equipment: Different equipment may be required according to different testing methods. For example, the air flow method requires breath-ability testing equipment, and the water vapor transfer method requires humidity control equipment, etc.

4. ASTM D737

Scope of application: Mainly used to evaluate the breath-ability performance of fabrics.

Test principle: The air flow method is used to measure the flow of gas through the sample to evaluate the breath-ability performance.

Test equipment: Air permeability tester includes air source, test fixture, flow meter, etc.

5. JIS L1096 Item 8.26 Method C

Scope of application: Widely used in the Japanese textile industry, mainly used to evaluate the breath-ability performance of fabrics.

Testing principle: The air flow method is used to measure the breath-ability of fabrics.

Test equipment: Air permeability tester includes air source, test fixture, flow meter, etc.

Among them, two standard methods, ISO 9237 and ASTM D737, are widely used. GB/T 5453-1997 This standard applies to a variety of textile fabrics, including industrial fabrics, non-woven fabrics and other breathable textile products. During the test, clothing fabrics and industrial fabrics were subtly distinguished through different pressure drops. The pressure drop of clothing fabrics was 100Pa, and the pressure drop of industrial fabrics was 200Pa. In GB/T5453-1985 "Fabric Breath-ability Test Methods", the air permeability (referring to the volume of air flowing through the unit area of the fabric per unit time under the specified pressure difference on both sides of the fabric) is used to measure the air permeability of the fabric. The revised standard GB /T 5453-1997 uses air permeability (referring to the rate of airflow vertically passing through the sample under the specified sample area, pressure drop and time conditions) to express the air permeability of the fabric.

ASTM D737 differs from the above standards in terms of application range, temperature and humidity, test area, pressure difference, etc. Taking into account the actual situation of import and export textile trade, it is planned to use different samples to compare and discuss the specific temperature and humidity, test area, pressure difference and other conditions of ISO 9237 and ASTM D737, select the applicability and representative conditions, and establish a suitable Industry standards for import and export trade.

Test result comparison

Fabric breath-ability results are closely related to the testing method used. Among the test results obtained using four different testing method standards: ISO 9237, GB/T 5453, ASTM D 737 and JIS L 1096: the air permeability tested according to GB/T 5453 and ISO 9237 is the same; according to GB/T5453 (ISO 9237) ) The air permeability tested is the smallest; the air permeability tested according to JIS L1096 is the largest; the air permeability tested according to ASTM D737 is in the middle. When the test area remains unchanged, the air permeability increases as the pressure drop increases, which is proportional to the pressure drop increase multiple. In summary, only by selecting appropriate testing methods based on product characteristics can the breathability of fabrics be correctly evaluated.

Detailed explanation of test steps (taking GB/T 24218-15 as an example)

Sampling is determined based on product standards or consultation with relevant parties. For testing equipment that can directly test large-size nonwoven fabrics, at least 5 parts of the large-size nonwoven fabric can be randomly selected as samples for testing; for testing equipment that cannot test large-size samples, a cutting mold or template can be used (Cut at least 5 samples of 100mmX100 mm size).

Place the sample from the ordinary environment into a standard atmospheric environment that complies with GB/T6529 and adjust the humidity to equilibrium.

Hold the edge of the specimen to avoid changing the natural state of the nonwoven test area.

Place the specimen on the test head and fix it with a clamping system to prevent distortion of the specimen or edge gas leakage during the test. When there is a difference in air permeability between the front and back sides of the sample, the test side should be noted in the test report. For coated specimens, place the specimen with the coated side down (toward the low pressure side) to prevent edge gas leakage.

Turn on the vacuum pump and adjust the air flow rate until the required pressure difference is reached, that is, 100Pa, 125Pa or 200Pa. On some new instruments, the test pressure value is digitally preselected, and the pressure difference on both sides of the measurement aperture is displayed digitally in the selected test unit to facilitate direct reading.

If a pressure gauge is used, wait until the required pressure value is stable and then read the air permeability value in liters per square centimeter seconds [L/(cm·s)].

Post time: May-06-2024