Inkomishi ye-thermos cishe iyinto okufanele ube nayo wonke umuntu.Izingane zingaphuza amanzi ashisayo nganoma yisiphi isikhathi ukuze zigcwalise amanzi, futhi abantu abaneminyaka ephakathi nasebekhulile bangacwilisa izinsuku ezibomvu kanye ne-wolfberry ukuze bathole ukunakekelwa kwezempilo.Kodwa-ke, izinkomishi ze-thermos ezingafanelekile zingaba nezingozi zokuphepha, izinsimbi ezisindayo ngokweqile, njll.

Izinga le-GB/T 40355-2021 eliphoqelekile likazwelonke lisebenza ezitsheni zansuku zonke ze-vacuum vacuum zensimbi engenasici ezithinta ukudla.Icacisa imigomo nezincazelo,ukuhlukaniswa kanye nemininingwane, izidingo, izindlela zokuhlola,imithetho yokuhlola, izimpawu, amalebula, imiyalelo yokusetshenziswa nokupakishwa, ukuthuthwa kanye nokugcinwa kweziqukathi ezivalekile zensimbi engagqwali.Izinga lizosetshenziswa ngokusemthethweni ngoMashi 1, 2022.

Ukuhlolwa kwenkomishi ye-thermos yensimbi engagqwali (ibhodlela, ibhodwe).

1.Ukubukeka

2. Izinto zensimbi engagqwali

3. Ukuchezuka kwevolumu

4. Ukusebenza kahle kwe-insulation

5.Ukuzinza

6.Ukumelana nomthelela

7.Ukubekwa uphawu

8.Izingxenye zokuvala kanye nephunga lamanzi ashisayo

I-9.Ukumelana kwamanzi ashisayo ezingxenyeni zenjoloba

10.Amandla okufaka isibambo kanye nendandatho yokuphakamisa

11.Amandla ezintambo kanye nezihlilingi

12.Ukunamathela kokugqoka

13.Ukunamathela kombhalo ophrintiwe namaphethini ebusweni

14.Amandla okujiya wekepisi lokuvala (ipulaki)

15.Ukusebenza kokusetshenziswa

1.Ukubukeka

-Ingaphezulu lendebe ye-thermos (ibhodlela, ibhodwe) kufanele ihlanzeke futhi ingabi nemihuzuko esobala.Izingxenye ezifinyeleleka ezandleni kufanele zingabi nama-burrs.

-Ingxenye eshiselwe kufanele ibe bushelelezi futhi ihlanzeke, ngaphandle kwama-pores, imifantu noma ama-burrs.

-Ingubo akufanele ivele, ixebuke noma igqwale.

-Umbhalo ophrintiwe kanye nezithombe kufanele kucace futhi kuphelele.

2.Stainless steel impahla

Ithangi langaphakathi nezinto zokwakha: Ithangi langaphakathi kanye nezinsiza zensimbi engagqwali ezithintana ngqo nokudla kufanele zenziwe ngezinto zensimbi engagqwali engu-12Cr18Ni9, 06Cr19Ni10, noma ezinye izinto zensimbi engagqwali ezinokumelana nokugqwala ezingekho ngaphansi kwamabanga ashiwo ngenhla.

Izinto zegobolondo:Igobolondo kufanele lenziwe ngensimbi engagqwali ye-austenitic.

3.Ukuchezuka kwevolumu

Ukuchezuka kwevolumu yenkomishi ye-thermos (ibhodlela, ibhodwe) kufanele kube phakathi kuka-±5% wevolumu yokulinganisa.

4.Ukusebenza kahle kwe-insulation

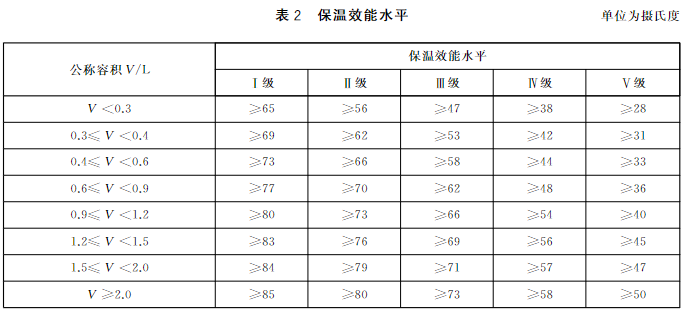

Izinga le-insulation ukusebenza kahle kwezinkomishi ze-thermos (amabhodlela, amabhodwe) lihlukaniswe ngamaleveli amahlanu.Izinga I liphakeme futhi izinga V liphansi kunawo wonke, njengoba kukhonjisiwe kuthebula elingezansi.

Umzimba oyinhloko wenkomishi ye-thermos (ibhodlela, ibhodwe) ushiywa obala isikhathi esingaphezu kwemizuzu engama-30 ezingeni lokushisa elishiwo endaweni yokuhlola futhi ugcwaliswe ngamanzi angaphezu kuka-96°C.Izinga lokushisa langempela elilinganiselwe lamanzi emzimbeni oyinhloko wenkomishi ye-thermos (ibhodlela, ibhodwe) lifinyelela (95±1)°C., vala isembozo sokuqala (i-stopper), futhi ngemva kwe-6h±5min, ulinganise izinga lokushisa lamanzi emzimbeni oyinhloko wenkomishi ye-thermos (ibhodlela, ibhodwe).Kudingeka ukuthi izinkomishi ze-thermos (amabhodlela nezimbiza) ezinamapulaki angaphakathi akufanele zibe ngaphansi kwezinga II;izinkomishi ze-thermos (amabhodlela namabhodwe) ngaphandle kwamapulaki angaphakathi akufanele zibe ngaphansi kwezinga elingu-V.

5.Ukuzinza

Ngaphansi kokusetshenziswa okuvamile, gcwalisa inkomishi ye-thermos (ibhodlela, ibhodwe) ngamanzi, uyibeke ebhodini lokhuni elingasheleli elitshekele ku-15°, bese ubheka ukuthi liyawa.

6.Ukumelana nomthelela

Gcwalisa inkomishi ye-thermos (ibhodlela, ibhodwe) ngamanzi okushisa asekamelweni, ilengise iqonde endaweni ephakeme engu-400mm ngelanyard, bese uyiphonsa ebhodini eliqinile elimiswe ngokuvundlile elinogqinsi olungaphezu kuka-30mm esimweni esingashintshile ukuze uhlole ukuqhekeka. kanye nomonakalo.Ngesikhathi esifanayo, hlola ukuthi ukusebenza kwe-thermal insulation kuyahlangabezana yini nemithetho ehambisanayo.

7.Ukubekwa uphawu

Faka u-50% wevolumu yamanzi ashisayo ngaphezu kuka-90 ℃ emzimbeni omkhulu wenkomishi ye-thermos (ibhodlela, ibhodwe), uyivale ngekepisi lokuqala (isivalo), umlomo ubheke phezulu, ushwibeka phezulu naphansi izikhathi eziyi-10 isikhathi esingu-1/ngesekhondi kanye ne-amplitude engu-500mm., hlola ukuvuza.

8.Izingxenye zokuvala kanye nephunga lamanzi ashisayo

Ngemva kokuhlanza inkomishi ye-thermos (ibhodlela, ibhodwe) ngamanzi afudumele aphakathi kuka-40℃ no-60℃, yigcwalise ngamanzi ashisayo angaphezu kuka-90℃, vala isivalo sokuqala (isivalo), bese usishiya imizuzu engama-30.Hlola ukuthi izingxenye zokuvala namanzi ashisayo zinalo yini iphunga elingavamile.

I-9.Ukumelana kwamanzi ashisayo ezingxenyeni zenjoloba

Faka izingxenye zenjoloba esitsheni sedivaysi yokufingqa kwe-reflux, ubilise kancane amahora angu-4, bese uzikhipha bese uhlola ukuthi zinamathele yini.Ngemva kokuyishiya amahora angu-2, hlola ngeso lenyama ukuthi ikhona yinideformation esobalangokubukeka.

10.Amandla okufaka isibambo kanye nendandatho yokuphakamisa

Lengisa inkomishi ye-thermos (ibhodlela, ibhodwe) esibambeni noma endandatho yokuphakamisa, bese ubeka isisindo esilingana nesisindo esiphindwe izikhathi ezingu-6 sendebe ye-thermos (ibhodlela, ibhodwe) eligcwele amanzi (kuhlanganise nazo zonke izesekeli), bese ulenga kancane inkomishi ye-thermos (kuhlanganise nazo zonke izesekeli).yigcine imizuzu emi-5, futhi uhlole ukuthi sikhona yini isibambo noma iringi yokuphakamisa.

11.Amandla ezintambo kanye nezihlilingi

Ukuhlolwa kwamandla ebhande: vula ibhande liye endaweni yalo ende kakhulu, bese ulenga inkomishi ye-thermos (ibhodlela, ibhodwe) ngebhande, futhi usebenzise isisindo esilingana nesisindo esiphindwe izikhathi ezingu-10 sendebe ye-thermos (ibhodlela, ibhodwe) eligcwele amanzi (kuhlanganise zonke izesekeli), njengokuthi Uma zingaboniswa, zilengise kancane enkomishini ye-thermos (ibhodlela, ibhodwe) bese uyigcina imizuzu emi-5.Hlola ukuthi izintambo, izihlilingi nokuxhumana kwazo kuyashelela noma kuphukile.

Ukuhlolwa kwamandla e-Sling: lengisa inkomishi ye-thermos (ibhodlela, ibhodwe) ngokusebenzisa isihlilingi, sebenzisa isisindo esilingana nesisindo sendebe ye-thermos ephindwe ka-10 (ibhodlela, ibhodwe) eligcwele amanzi (kuhlanganise nazo zonke izesekeli), bese ulenga kancane enkomishini ye-thermos isibalo (ibhodlela, ibhodwe), yigcine imizuzu emi-5, bese uhlola isihlilingi nokuxhumana kwayo.

12.Ukunamathela kokugqoka

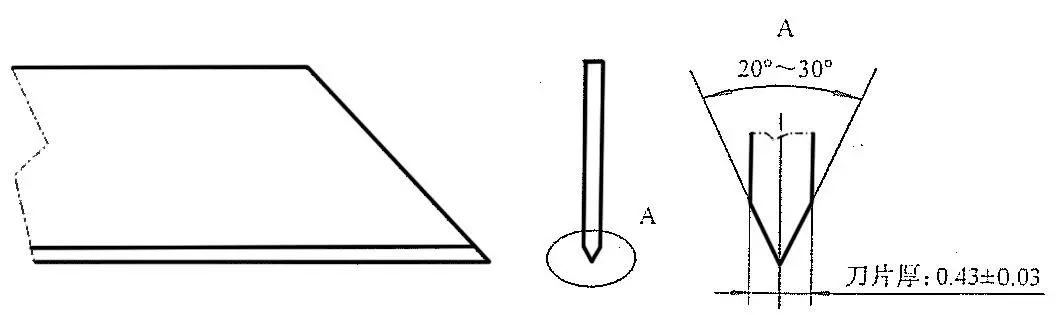

Sebenzisa ithuluzi lokusika elinohlangothi olulodwa eline-engeli ye-blade engu-20° ukuya ku-30° kanye nogqinsi lweblade elingu-(0.43±0.03) mm (njengoba kuboniswe ngezansi), sebenzisa amandla aqondile ngisho nangaphezulu endaweni enamathelayo ezohlolwa, futhi klwebha i-100 (10× 10) 1mm2 igridi yebhodi lokuhlola, bese unamathisele itheyiphu enamathelayo ezwela ukucindezela enobubanzi obungu-25mm namandla okunamathela angu-(10±1) N/25mm kuyo, bese ukhumula itheyipu ngamandla ibheke ngakubo. kuma-engeli angakwesokudla phezulu, futhi ubale inani letheyiphu elingakahlutshiwe Inani lamagridi okuhlola ebhodini elisele, ngokuvamile kuyadingeka ukuthi okokunamathela kufanele kugcine amagridi ebhodi okuhlola angaphezu kwangu-92.

Umdwebo wohlelo lwethuluzi lokusika elinqenqemeni elilodwa

13.Ukunamathela kombhalo ophrintiwe namaphethini ebusweni

Embhalweni nephethini, namathisela itheyiphu enamathelayo ezwela ukucindezela enobubanzi obungu-25mm namandla okunamathela angu-(10±1) N/25mm.Bese ususa itheyiphu ngamandla kuma-engeli angakwesokudla phezulu bese uhlola ukuthi iwile yini.

14.Iamandla e-screwingyekepisi lokuvala (ipulaki)

Qala uqinise ikhava (ipulaki) ngesandla, bese usebenzisa i-torque engu-3 N·m embozweni (ipulaki), bese uhlola ukuthi intambo inamazinyo ashelelayo yini.

15.Ukusebenza kokusetshenziswa

Hlola ngokwakho futhi uhlole ukuthi izingxenye ezihambayo zenkomishi ye-thermos (ibhodlela, ibhodwe) zifakwe ngokuqinile, zinyakaza kalula, futhi zisebenza ngokujwayelekile.

Isikhathi sokuthumela: Nov-25-2023