Ikomityi ye-thermos iphantse ibe yinto efunekayo kumntu wonke.Abantwana banokusela amanzi atshisayo nangaliphi na ixesha lokuzalisa amanzi, kwaye abantu abaneminyaka ephakathi kunye nabantu abadala banokucwina iintsuku ezibomvu kunye ne-wolfberry kukhathalelo lwempilo.Nangona kunjalo, iikomityi ze-thermos ezingafanelekanga zinokuba neengozi zokhuseleko, iintsimbi ezinzima kakhulu, njl.

Umgangatho ogunyazisiweyo wesizwe we-GB / T 40355-2021 uyasebenza kwimigqomo ye-vacuum ye-vacuum yemihla ngemihla yensimbi engenasici edibana nokutya.Ichaza imigaqo kunye neenkcazo,ulwahlulo kunye neenkcukacha, iimfuno, iindlela zovavanyo,imithetho yokuhlola, iimpawu, iilebhile, imiyalelo yokusetyenziswa kunye nokupakishwa, ukuthuthwa kunye nokugcinwa kwentsimbi ye-vacuum insulated containers.Umgangatho uya kuphunyezwa ngokusesikweni ngomhla woku-1 kuMatshi ka-2022.

Ukuhlolwa kwekomityi ye-thermos yensimbi engenasici (ibhotile, imbiza).

1.Imbonakalo

2. Izinto zensimbi ezingenasici

3. Ukutenxa umthamo

4. Ukusebenza kakuhle kwe-insulation

5.Uzinzo

6.Ukuchasana kwempembelelo

7.Ukutywinwa

8.Iinxalenye zokutywina kunye nevumba lamanzi ashushu

I-9.Ukuchasana kwamanzi ashushu kwiindawo zerabha

10.Amandla okufakwa komqheba kunye nomsesane wokuphakamisa

11.Amandla eentambo kunye nezilingi

12.Ukunamathela kwi-coating

13.Ukunamathela kombhalo oshicilelweyo kunye neepateni kumphezulu

14. Amandla okujijwa komnqwazi wokutywina (iplagi)

15.Ukusetyenziswa kokusebenza

1.Imbonakalo

-Umphezulu wekomityi ye-thermos (ibhotile, imbiza) kufuneka ihlambuluke kwaye ingabikho imikrwelo ebonakalayo.Amalungu afikelelekayo ezandleni kufuneka angabi nazibhula.

-Inxalenye edibeneyo kufuneka ihambe kakuhle kwaye icoceke, ngaphandle kweepores, i-cracks okanye i-burrs.

-Into yokugquma akufunekanga ivele, ixobulwe okanye ibe nomhlwa.

-Isicatshulwa esishicilelweyo kunye nemizobo kufuneka icace kwaye iphelele.

2.Izinto zensimbi ezingenasici

Itanki yangaphakathi kunye nezixhobo zokuncedisa: Itanki yangaphakathi kunye nezixhobo zensimbi ezingenasici ezidibana ngokuthe ngqo kunye nokutya kufuneka zenziwe nge-12Cr18Ni9, 06Cr19Ni10 izinto zensimbi ezingenasici, okanye ezinye izinto zensimbi ezingenasici ezinokumelana ne-corrosion engekho ngaphantsi kwamabanga achazwe ngasentla.

Isixhobo seqokobhe:Iqokobhe kufuneka lenziwe ngentsimbi ye austenitic stainless.

3.Ukutenxa umthamo

Ukutenxa umthamo wekomityi ye-thermos (ibhotile, imbiza) kufuneka ibe phakathi kwe-± 5% yomthamo wegama.

4.Ukusebenza kakuhle kwe-insulation

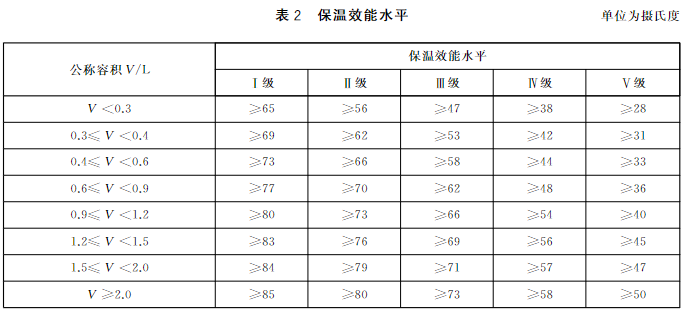

Inqanaba lokuphumelela kwe-insulation yeekomityi ze-thermos (iibhotile, iimbiza) zihlulwe zibe ngamanqanaba amahlanu.Inqanaba I lelona liphezulu kwaye inqanaba V lelona lisezantsi, njengoko kubonisiwe kwitheyibhile engezantsi.

Umzimba ongundoqo wekomityi ye-thermos (ibhotile, imbiza) ushiywe evezweni ngaphezu kwemizuzu engama-30 kubushushu obuchaziweyo bemekobume yovavanyo kwaye izaliswe ngamanzi angaphezu kwama-96°C.Obona bushushu bulinganisiweyo bamanzi kumzimba oyintloko wekomityi ye-thermos (ibhotile, imbiza) bufikelela ku-(95±1)°C., vala isiciko sokuqala (i-stopper), kwaye emva kwe-6h± 5min, ukulinganisa ubushushu bamanzi kumzimba oyintloko wekomityi ye-thermos (ibhotile, imbiza).Kuyimfuneko ukuba iikomityi ze-thermos (iibhotile kunye neembiza) ezineeplagi zangaphakathi akufanele zibe ngaphantsi kwenqanaba le-II;iikomityi ze-thermos (iibhotile kunye neembiza) ezingenazo iiplagi zangaphakathi akufanele zibe ngaphantsi kwe-V.

5.Uzinzo

Ngaphantsi kokusetyenziswa okuqhelekileyo, gcwalisa ikomityi ye-thermos (ibhotile, imbiza) ngamanzi, uyibeke kwibhodi yeplanga engatyibilikiyo ethambekele kwi-15 °, kwaye ujonge ukuba iyabhukuqa na.

6.Ukuchasana kwempembelelo

Gcwalisa ikomityi ye-thermos (ibhotile, imbiza) ngamanzi obushushu begumbi, yixhome ngokuthe nkqo kumphakamo oyi-400mm ngelanyard, kwaye uyiwise kwibhodi eqinileyo emiswe ngokuthe tye enobunzima obungaphezulu kwe-30mm kwimeko engashukumiyo ukujonga iintanda. kunye nomonakalo.Ngexesha elifanayo, khangela ukuba i-thermal insulation performance idibana nemimiselo ehambelanayo.

7.Ukutywinwa

Beka i-50% yomthamo wamanzi ashushu ngaphezulu kwe-90 ℃ kumzimba ophambili wekomityi ye-thermos (ibhotile, imbiza), uyitywine ngesivalo sokuqala (isithinteli), umlomo ubheke phezulu, ujiwuze unyuke nasezantsi amaxesha ali-10 rhoqo. ye-1 ixesha/umzuzwana kunye ne-amplitude ye-500mm., khangela iindawo ezivuzayo.

8.Iinxalenye zokutywina kunye nevumba lamanzi ashushu

Emva kokucoca ikomityi ye-thermos (ibhotile, imbiza) ngamanzi afudumeleyo phakathi kwe-40℃ kunye ne-60℃, yigcwalise ngamanzi ashushu ngaphezu kwe-90℃, vala isiciko sokuqala (isithinteli), kwaye usishiye imizuzu engama-30.Khangela ukuba iindawo zokutywina kunye namanzi ashushu analo naliphi na ivumba elingaqhelekanga.

I-9.Ukuchasana kwamanzi ashushu kwiindawo zerabha

Beka iindawo zerabha kwisitya se-reflux condensation device, ubilise kancinane iiyure ezi-4, uze uzikhuphe kwaye ukhangele ukuba zincangathi.Emva kokuyishiya iiyure ze-2, jonga ngeso lenyama ukuba kukho nayiphi nadeformation ebonakalayongenkangeleko.

10.Amandla okufakwa komqheba kunye nomsesane wokuphakamisa

Hangisa ikomityi ye-thermos (ibhotile, imbiza) ngomqheba okanye umsesane wokuphakamisa, kwaye ubeke ubunzima obulingana namaxesha ama-6 ubunzima bekomityi ye-thermos (ibhotile, imbiza) ezaliswe ngamanzi (kubandakanywa nazo zonke izincedisi), kwaye uyixhome kancinci indebe ye-thermos (kubandakanywa nazo zonke izixhobo).yigcine imizuzu emi-5, kwaye ujonge ukuba kukho isiphatho okanye umsesane wokuphakamisa.

11.Amandla eentambo kunye nezilingi

Uvavanyo lwamandla e-strap: vula intambo ukuya kwindawo yayo ende, emva koko uxhome ikomityi ye-thermos (ibhotile, imbiza) ngomtya, kwaye usebenzise ubunzima obulingana namaxesha ali-10 ubunzima bekomityi ye-thermos (ibhotile, imbiza) ezaliswe ngamanzi (kubandakanywa zonke izincedisi), ezifana Ukuba akuboniswanga, yixhome kancinci kwikomityi ye-thermos (ibhotile, imbiza) kwaye uyigcine imizuzu emi-5.Jonga ukuba imitya, izilingi kunye noqhagamshelo lwazo ziyatyibilika okanye zophukile.

Uvavanyo lwamandla esilingi: xhoma ikomityi ye-thermos (ibhotile, imbiza) ngesilingi, sebenzisa ubunzima obulingana namaxesha ali-10 ubunzima bekomityi ye-thermos (ibhotile, imbiza) ezaliswe ngamanzi (kubandakanywa nazo zonke izixhobo), kwaye uyixhome kancinci kwikomityi ye-thermos. umfanekiso (ibhotile, imbiza), yigcine imizuzu emi-5, kwaye ukhangele i-sling kunye nokudibanisa kwayo.

12.Ukunamathela kwi-coating

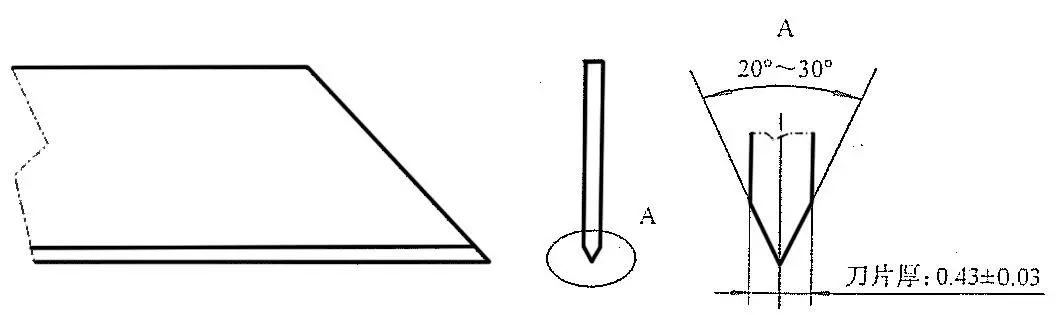

Sebenzisa isixhobo sokusika esinomphetho omnye esine-engile ye-blade engama-20 ° ukuya kwi-30 ° kunye nobukhulu be-blade (0.43±0.03) mm (njengoko kubonisiwe ngezantsi), sebenzisa ngokuthe nkqo nangokunyanzeliswa kumphezulu wengubo oza kuvavanywa, kwaye krwempa i-100 (10 × 10) 1mm2 igridi yokukhangela ibhodi, kwaye uncamathele iteyiphu encamathelayo enoxinzelelo olunobubanzi obungama-25mm kunye namandla okuncamathela (10±1) N/25mm kuyo, uze uxobule iteyiphu ngamandla kwicala kwii-engile ezichanekileyo kumphezulu, kwaye ubale inani le tape engekaxobulwa.

Umzobo weSchematic wesixhobo sokusika umgca omnye

13.Ukunamathela kombhalo oshicilelweyo kunye neepateni kumphezulu

Kwisicatshulwa kunye nephethini, unamathele i-tape yokubambelela enoxinzelelo kunye nobubanzi be-25mm kunye namandla okubambelela (10 ± 1) N / 25mm.Emva koko hlambulula i-tape ngamandla kwii-angles ezifanelekileyo kumphezulu kwaye ukhangele ukuba iwile.

14.Iamandla okujijayecap yokutywina (iplagi)

Okokuqala qinisa isigqubuthelo (iplagi) ngesandla, uze usebenzise i-torque ye-3 N · m kwisigqubuthelo (iplagi), kwaye ukhangele ukuba intambo inamazinyo ajikelezayo.

15.Ukusetyenziswa kokusebenza

Ukuhlola ngesandla kunye nokubonwayo ukuba iindawo ezihambayo zekomityi ye-thermos (ibhotile, imbiza) zifakwe ngokuqinileyo, zihamba ngokuguquguqukayo, kwaye zisebenza ngokuqhelekileyo.

Ixesha lokuposa: Nov-25-2023